Hot-melt pressure-sensitive adhesive and preparation method thereof

A technology of hot-melt pressure-sensitive adhesives and mass parts, which is applied in the direction of adhesives, adhesive types, mineral oil hydrocarbon copolymer adhesives, etc., and can solve problems such as cracking of the adhesive surface, reduction, and failure to solve the cohesion of the adhesive layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

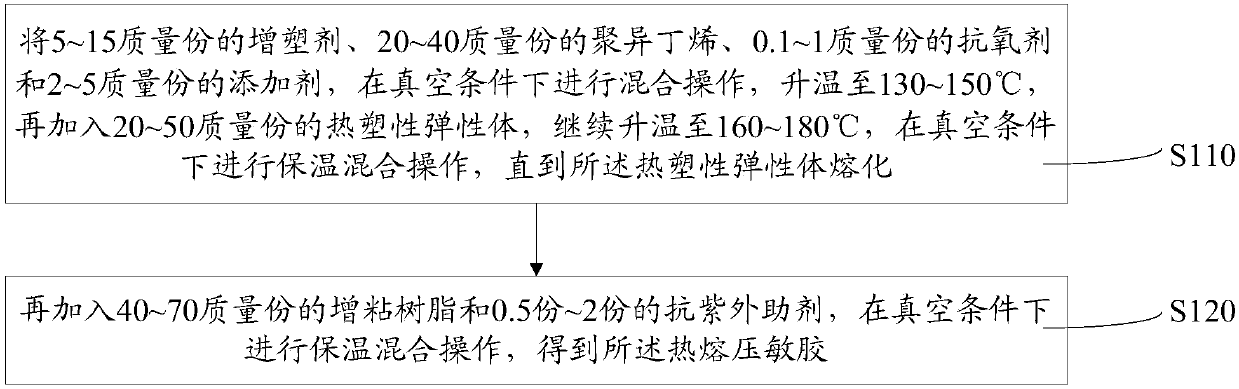

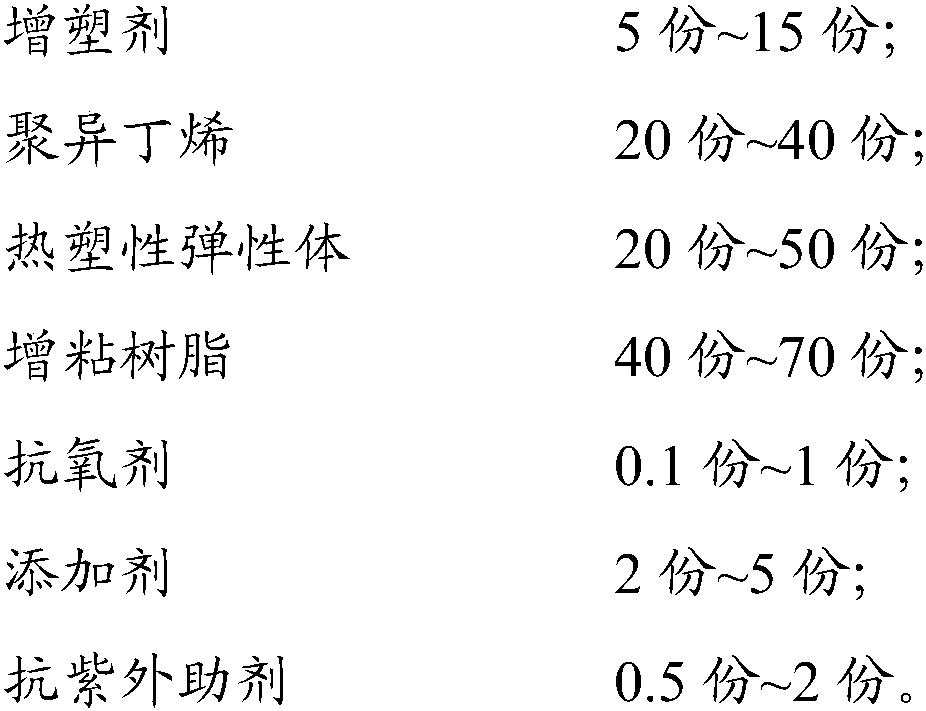

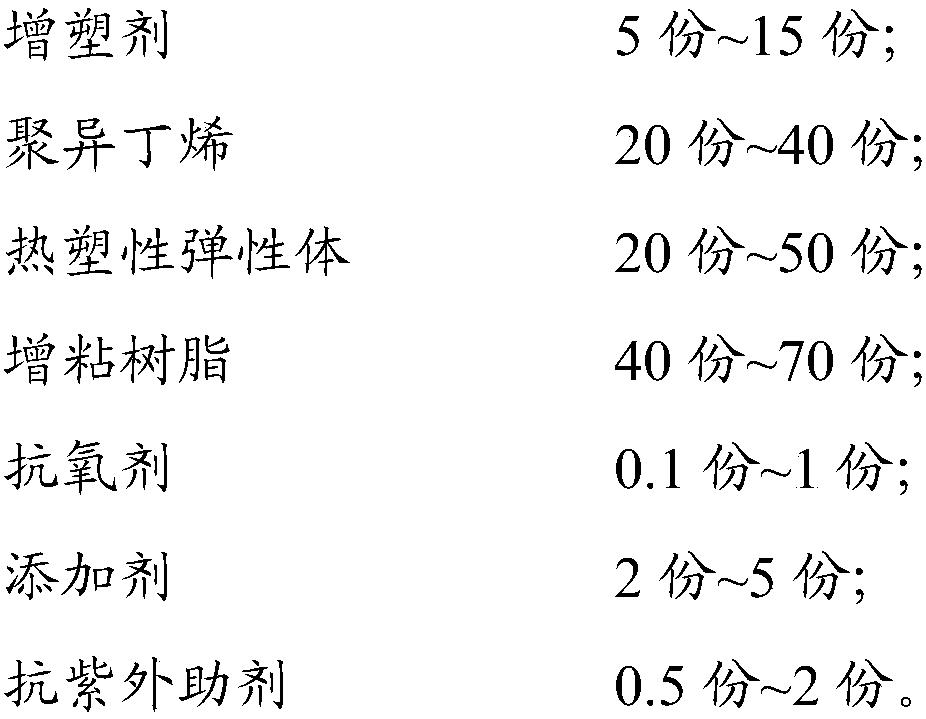

[0036] see figure 1 , the preparation method of hot-melt pressure-sensitive adhesive in one embodiment, comprises the steps:

[0037] S110: Mix 5-15 parts by mass of plasticizer, 20-40 parts by mass of polyisobutylene, 0.1-1 part by mass of antioxidant and 2-5 parts by mass of additives under vacuum conditions, and heat up to 130-150° C., then add 20-50 parts by mass of thermoplastic elastomer, continue to heat up to 160-180° C., and carry out heat preservation and mixing operation under vacuum until the thermoplastic elastomer melts.

[0038] Through step S110, the thermoplastic elastomer can be fully heated and melted, that is, the thermoplastic elastomer can be completely melted, and then the thermoplastic elastomer and other components can be mixed more fully and evenly.

[0039] S120: adding 40-70 parts by mass of a tackifying resin and 0.5-2 parts of an anti-ultraviolet additive, and performing heat preservation and mixing operations under vacuum conditions to obtain th...

Embodiment 1

[0045] Add 1.5kg of naphthenic oil, 2kg of polyisobutylene, 0.1kg of β(3,5-di-tert-butyl-4-hydroxyphenyl) pentaerythritol propionate, and 0.3kg of nano-silica powder into the reactor , low-speed vacuum stirring, heating to 130-150°C, adding 2kg of thermoplastic elastomer, continuing to heat up to 160-180°C, keeping warm and vacuum stirring for 60-120min until the elastomer is completely melted; adding 4kg of rosin resin, 0.2kg of 2-(2ˊ-hydroxy-5ˊ-methylphenyl)benzotriazole, heat-preserved and vacuum-stirred for 40-90min, until it dissolves evenly, and discharges to obtain hot-melt pressure-sensitive polymer self-adhesive waterproof membrane with good weather resistance glue. The hot-melt pressure-sensitive adhesive of the invention has good wettability to HDPE and TPO waterproof membranes, has excellent anti-ultraviolet aging performance, good heat-aging resistance, high peeling strength, simple process and low cost.

Embodiment 2

[0047] 1.5kg of naphthenic oil, 2kg of polyisobutylene, 0.1kg of β (3,5-di-tert-butyl-4-hydroxyphenyl) pentaerythritol propionate, 0.1kg of nano-silica powder, 0.2kg of nano-titanium Add white powder to the reaction kettle, stir in low-speed vacuum, heat to 130-150°C, add 2kg of thermoplastic elastomer, continue to heat up to 160-180°C, keep warm and vacuum stir for 60-120min, until the elastomer is completely melted; add 4kg rosin resin, 0.2kg of 2-(2'-hydroxyl-5'-methylphenyl)benzotriazole, heat-preserved and vacuum-stirred for 40-90min, until it dissolves evenly, and the material is discharged to obtain a weather-resistant polymer self-adhesive Waterproof membrane hot melt pressure sensitive adhesive. The hot-melt pressure-sensitive adhesive of the invention has good wettability to HDPE and TPO waterproof membranes, has excellent anti-ultraviolet aging performance, good heat-aging resistance, high peeling strength, simple process and low cost.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com