Fire-retardant resin-based copper clad laminate and preparation method thereof

A flame retardant resin, copper plate technology, used in chemical instruments and methods, flat products, other household appliances, etc., can solve the problems of low humidity and heat resistance, high dielectric constant, low shrinkage rate of the plate, and achieve excellent flexibility, Uniform smoothness, high density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

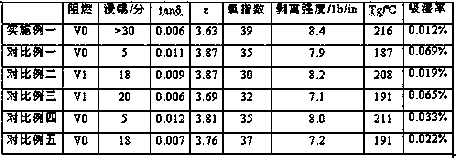

Examples

Embodiment 1

[0048] (1) Disperse nano-silica foam in toluene, then add vinyl propionate, tert-butyl diazoacetate and tert-butyl nitrite; stir at 80°C for 15 minutes; then add tetramethylethylenediamine After dispersing evenly, add dibutylzinc dilaurate, reflux for 7 hours, and finally add acetone to obtain a modified silica foam system with a solid content of 25%;

[0049] (2) At 25°C, mix pinacolborane, tetrahydrofuran and 2,3-epoxycyclopentylcyclopentyl ether, stir for 35 minutes, add 2-aminoacetophenone, and continue stirring for 20 minutes; then add Pyridinium m-nitrobenzenesulfonate, glyceryl monostearate, and continued to stir for 20 minutes to obtain a monofunctional epoxy system;

[0050] (3) Add graphene oxide to diglycidyl phthalate, stir at 125°C for 20 minutes, then add 1,8-octanedithiol, and stir at 130°C for 50 minutes to obtain a bifunctional epoxy system;

[0051] (4) Add the modified silica foam system to the bifunctional epoxy system, stir at 130°C for 50 minutes, then a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com