Bubbling type external reaction system and method for synthesizing polyoxymethylene dimethyl ether

A polymethoxydimethyl ether and reaction system technology, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of high production cost, low synthesis conversion rate and yield, etc., and achieve conversion degree of realization, improvement of absorption effect, effect of high-efficiency reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

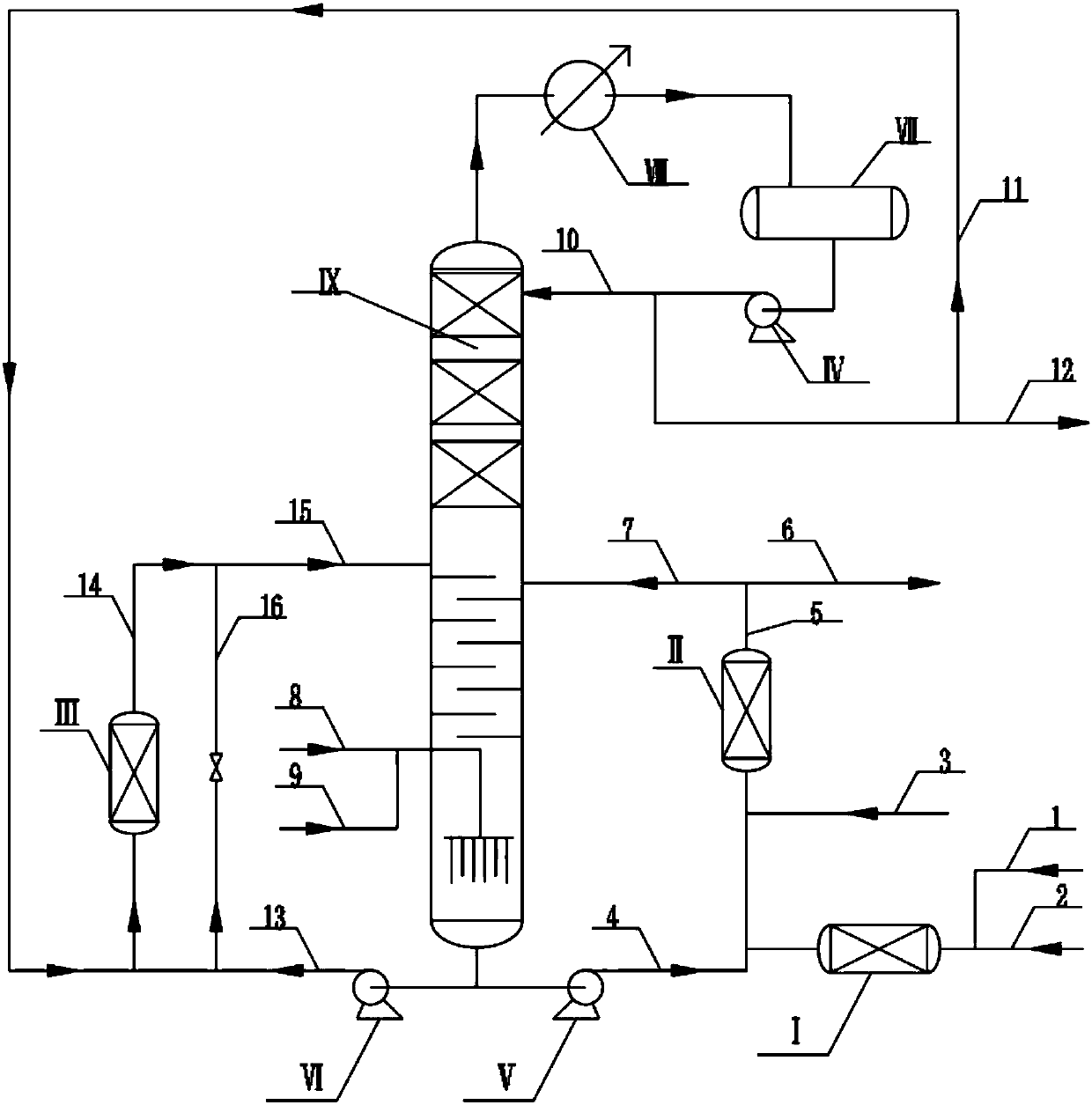

[0036] like figure 1 As shown, a bubbling external reaction system for the synthesis of polyoxymethylene dimethyl ether includes a bubbling absorption tower IX, a first external reactor II, a pre-reactor I and a second external reactor III; The output end of the pre-reactor I is connected to the input end of the external reactor I, and the input end of the first external reactor II is also connected to the output end of the bubbling absorption tower IX through the discharge pump V. The first The output end of the external reactor II is respectively connected to the input end of the bubble absorption tower IX and the separation unit; the output end of the bottom of the bubble absorption tower IX is respectively connected to the middle part of the bubble absorption tower IX and the second external The input end of the reactor III is connected, and the output end of the second external reactor III is connected with the middle part of the bubbling absorption tower IX. A condenser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com