Method used for preparing high purity nanoscale titanium sub-oxides at low temperature

A titanium suboxide and nano-scale technology, which is applied in the low-value oxide of titanium, titanium oxide/hydroxide, nanotechnology, etc., can solve the problems of material performance degradation, particle growth, growth, etc., and achieve production efficiency High, short preparation process, the effect of realizing continuous industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

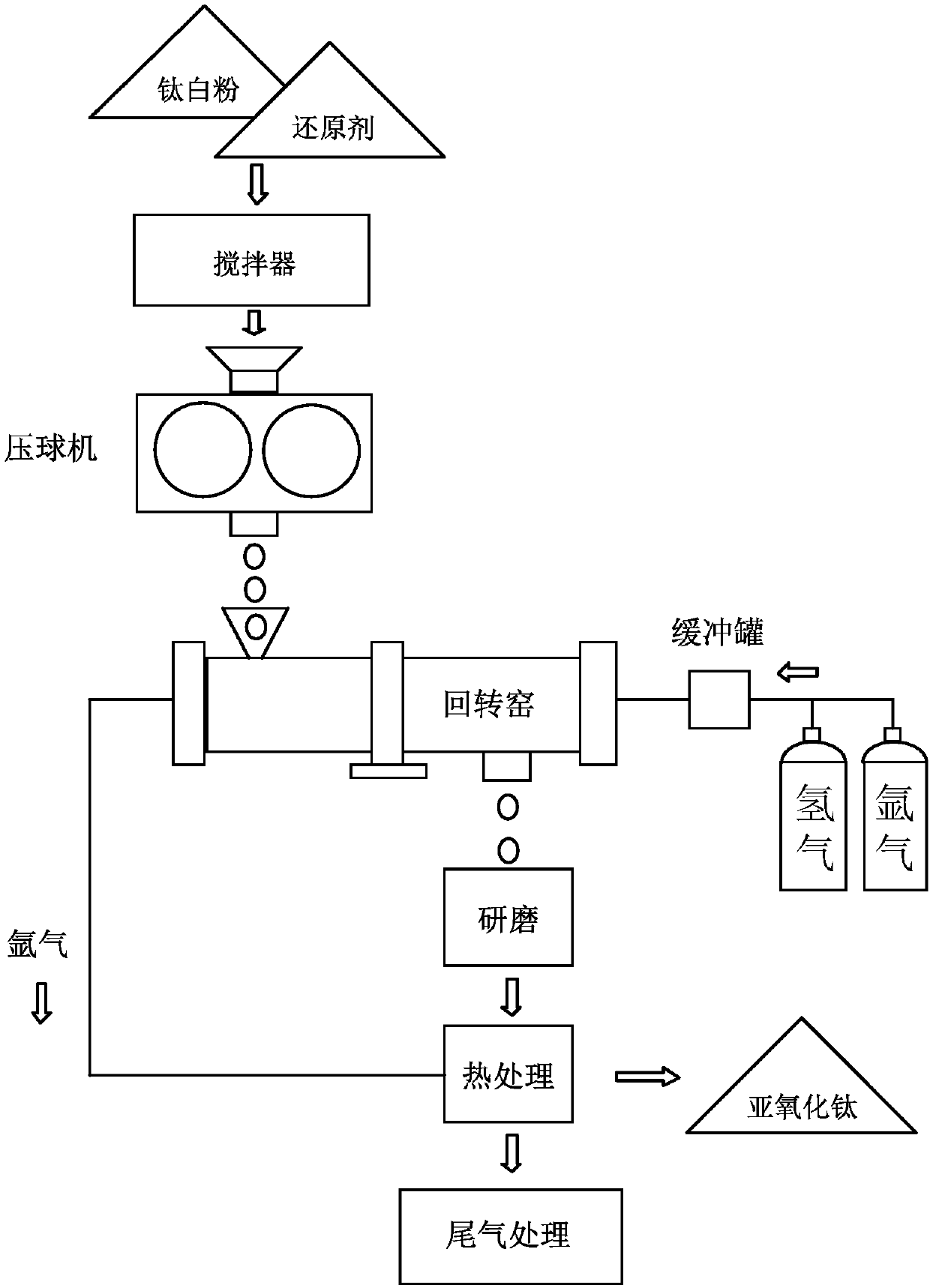

Method used

Image

Examples

Embodiment 1

[0026] Weigh 8000g of nano-sized rutile titanium dioxide, add 3000g of asparagine and 1000g of asparagine aqueous solution with a concentration of 5%, press into balls after mixing, and dry the balls at 105°C for 3 hours; then dry the dried The pellets are sent into the microwave rotary kiln. The temperature in the heating section of the microwave rotary kiln is set at 850°C, and the heating time is 30 minutes. After the reaction is completed, it is cooled rapidly; the reduced pellets are crushed and then put into a ball mill for grinding. The grinding time for 50min. Finally, the ground nano-scale titanium dioxide is subjected to heat treatment at a heat treatment temperature of 250° C. and a heat treatment time of 3 hours to finally obtain high-purity nano-scale titanium dioxide.

[0027] TiO 2 The recovery mechanism is as follows:

[0028] TiO 2 +C 4 h 8 N 2 o 3 → Ti 4 o 7 +CO 2 +H 2 O+N 2 …...(1)

[0029] The analysis result of high-purity nano-scale titanium ...

Embodiment 2

[0031] Weigh 8000g of nano-sized rutile titanium dioxide, add 3000g of glutamine and 1000g of 5% glutamine aqueous solution, mix well, press into balls, and dry the balls at 105°C for 3 hours; then dry the dried The pellets are sent into the microwave rotary kiln. The temperature in the heating section of the microwave rotary kiln is set at 800°C, and the heating time is 40 minutes. After the reaction is completed, it is cooled rapidly; the reduced pellets are crushed and then put into a ball mill for grinding. The grinding time for 50min. Finally, the ground nano-scale titanium dioxide is subjected to heat treatment at a heat treatment temperature of 250° C. and a heat treatment time of 3 hours to finally obtain high-purity nano-scale titanium dioxide.

[0032] TiO 2 The recovery mechanism is as follows:

[0033] TiO 2 +C 5 h 10 N 2 o 3 → Ti 4 o 7 +CO 2 +H 2 O+N 2 …...(2)

[0034] The analysis result of high-purity nano-scale titanium dioxide is: the content of t...

Embodiment 3

[0036] Weigh 8000g of nano-scale rutile titanium dioxide, add 1500g of asparagine, 1500g of glutamine and 1000g of (2.5% of glutamine+2.5% of asparagine) aqueous solution, mix and press into balls. The pellets were dried at 105°C for 3 hours; then the dried pellets were sent into the microwave rotary kiln, the temperature of the heating section of the microwave rotary kiln was set at 750°C, the heating time was 60 minutes, and the reaction was completed and cooled rapidly; the reduced pellets were passed through After crushing, put it into a ball mill for grinding, and the grinding time is 50 minutes. Finally, the ground nano-scale titanium dioxide is subjected to heat treatment at a heat treatment temperature of 250° C. and a heat treatment time of 3 hours to finally obtain high-purity nano-scale titanium dioxide.

[0037] TiO 2 The recovery mechanism is as follows:

[0038] TiO2 +C 4 h 8 N 2 o 3 +C 5 h 10 N 2 o 3 →Ti 4 o 7 +CO 2 +H 2 O+N 2 ......(3)

[0039] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com