Mxene-coated composite electrode material and preparation method therefor

A composite electrode and electrode material technology, applied in battery electrodes, nanotechnology for materials and surface science, circuits, etc., can solve the problems affecting the performance of electrode materials, damage of electrode materials, severe direct contact reaction, etc., and reduce the dissolution rate. and self-discharge effects, reducing voids, and enhancing conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] Disclosed in one embodiment of the present invention is a kind of preparation method of the composite electrode material of Mxene coating, described method comprises the steps:

[0037] (1) Add the electrode material into the solvent, stir evenly, then add Mxene, and stir to obtain a uniform mixed solution.

[0038] (2) The resulting mixed solution is sprayed and granulated by a spray dryer to obtain Mxene-coated electrode material powder.

[0039] (3) The obtained composite electrode material powder is sintered under the protection of an inert gas and then cooled.

[0040] The solvent in the preparation method step (1) of the present invention is water, ethanol, dimethyl sulfoxide, benzene, toluene, xylene, pentane, hexane, cyclohexane, cyclohexanone, tolylcyclohexanone, One or a mixture of two or more of chlorobenzene, dichlorobenzene, dichloromethane, methanol, ethanol, isopropanol, acetone, ethylene glycol, acetonitrile, pyridine, and phenol.

[0041] The electrod...

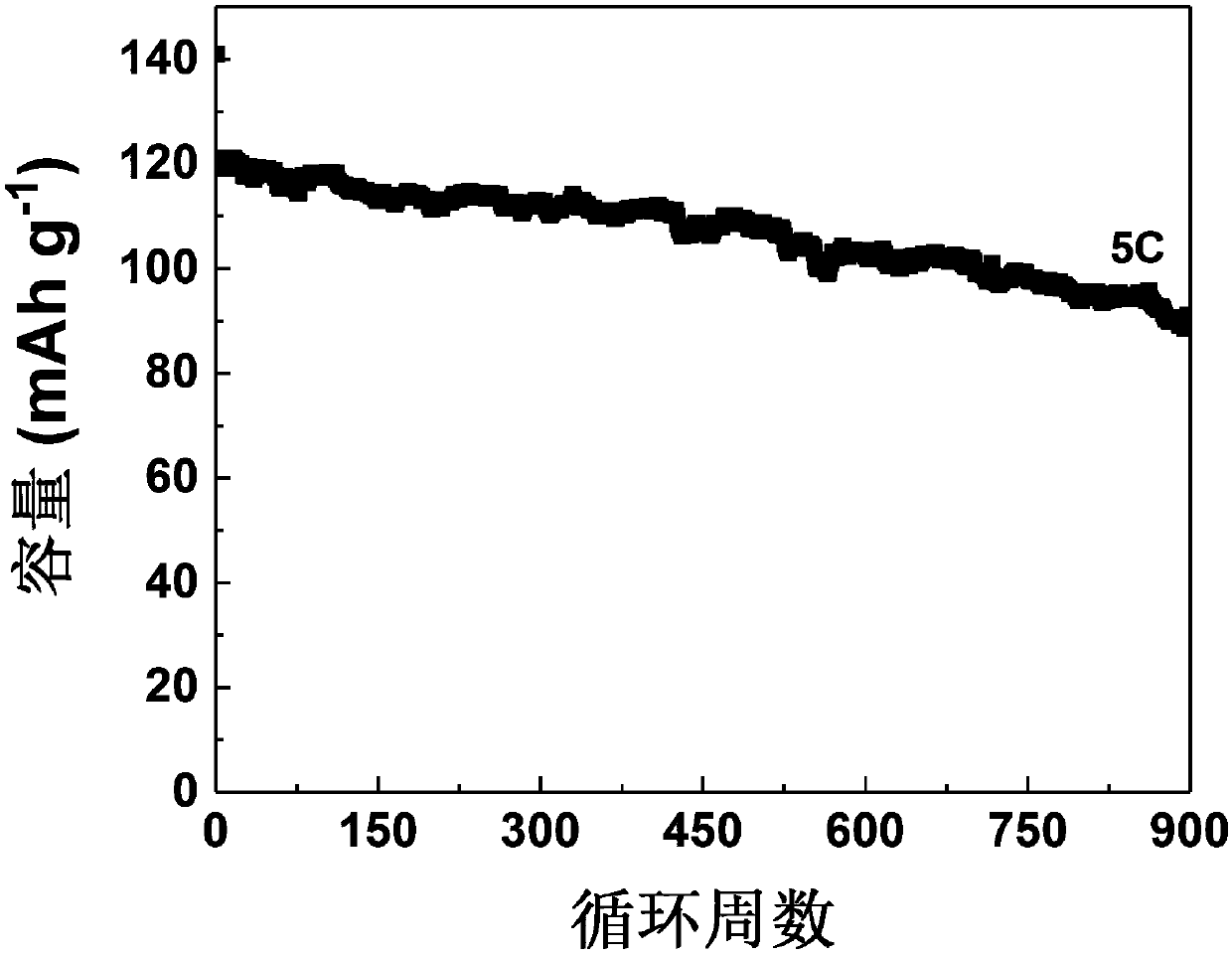

Embodiment 1

[0046] (1) Will Li 4 Ti 5 o 12 Weigh 100g of the powder and add it into 200ml dimethyl sulfoxide, stir magnetically for 3h, and mix evenly.

[0047] (2) Add 5 g of Mxene accounting for 5% of the mass of the lithium titanate powder to the obtained mixed liquid, stir it magnetically for 5 h, and mix uniformly.

[0048] (3) The obtained mixed solution is sprayed and granulated by a spray dryer to obtain Mxene uniformly coated lithium titanate powder. The spray drying parameters are set as, the inlet temperature is 250°C, and the outlet temperature is 90°C.

[0049] (4) Put the obtained powder into a crucible, put it in a tubular electric furnace, evacuate, and pass nitrogen, repeat the process of evacuating and nitrogen 3 times, and heat at 300°C for 2 hours to obtain the Mxene-coated lithium titanate negative electrode material.

Embodiment 2

[0051] (1) Will Li 4 Ti 5 o 12 Weigh 100g of the powder and add it into 200ml dimethyl sulfoxide, stir magnetically for 3h, and mix evenly.

[0052] (2) Add 1 g of Mxene accounting for 1% of the mass of the lithium titanate powder to the obtained mixed liquid, stir magnetically for 5 hours, and mix uniformly.

[0053] (3) The obtained mixed solution is sprayed and granulated by a spray dryer to obtain Mxene uniformly coated lithium titanate powder. The spray drying parameters are set as, the inlet temperature is 250°C, and the outlet temperature is 90°C.

[0054] (4) Put the obtained powder into a crucible, put it in a tubular electric furnace, evacuate, and pass nitrogen, repeat the process of evacuating and nitrogen 3 times, and heat at 300°C for 2 hours to obtain the Mxene-coated lithium titanate negative electrode material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com