OLED packaging structure and OLED packaging method

An encapsulation structure and encapsulation method technology, applied in the field of OLED, can solve the problems of destroying electrical properties and stability, OLED pixel luminous brightness changes, affecting OLED display quality, etc., to achieve the effects of improving life expectancy, good protection, and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

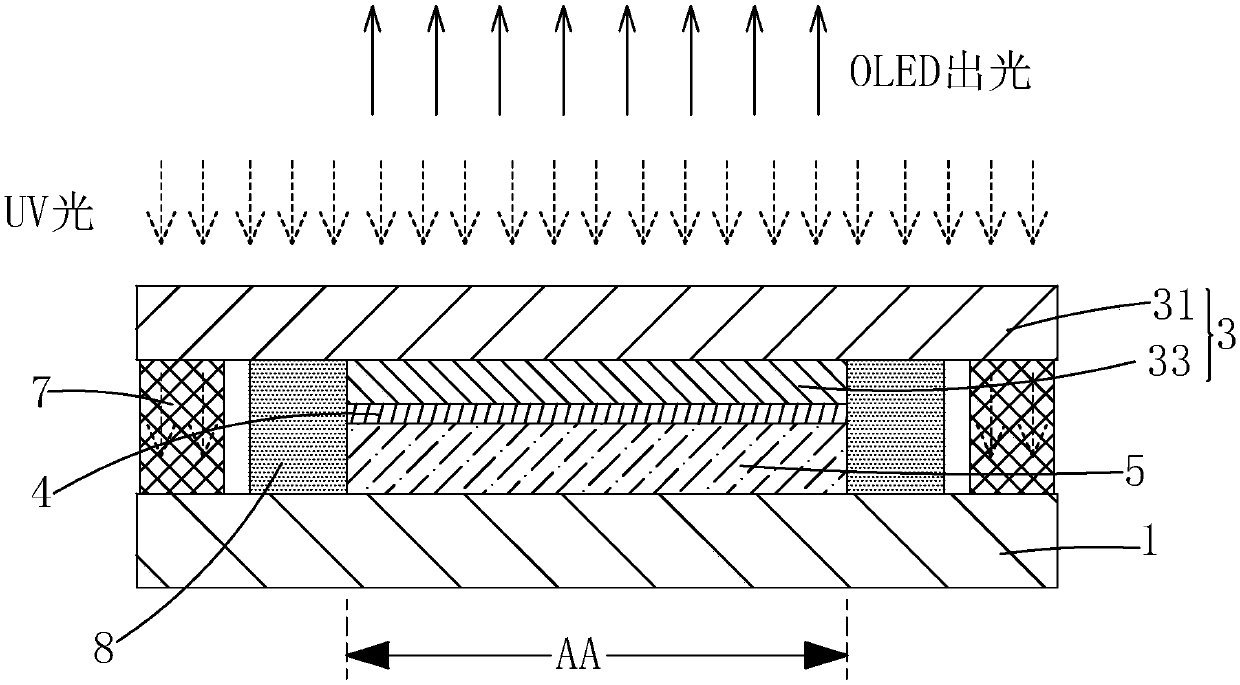

[0032] The invention provides an OLED packaging structure. figure 1 Shown is the first embodiment of the OLED packaging structure of the present invention, including a TFT substrate 1, a packaging cover 3 opposite to the TFT substrate 1, and a TFT substrate 1 close to the packaging cover in the effective display area AA of the OLED. The OLED device 5 on one side of the board 3 and the sealant 7 disposed between the TFT substrate 1 and the packaging cover 3 around the effective display area AA of the OLED.

[0033] The packaging cover plate 3 is improved compared with the prior art, and it includes a packaging substrate 31 and a UV blocking layer 33 disposed on the side of the packaging substrate 31 close to the TFT substrate 1 and correspondin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com