Preparation method of Nd-Fe-Co ternary alloy magnetic nanowire

A magnetic nanometer and ternary alloy technology, applied in the application of magnetic film to substrate, nanostructure application, etc., can solve the problems that the uniformity of structure affects the quality of the film, and the law of influence is complex, and achieves uniform size and high deposition rate. , the effect of improving coercivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

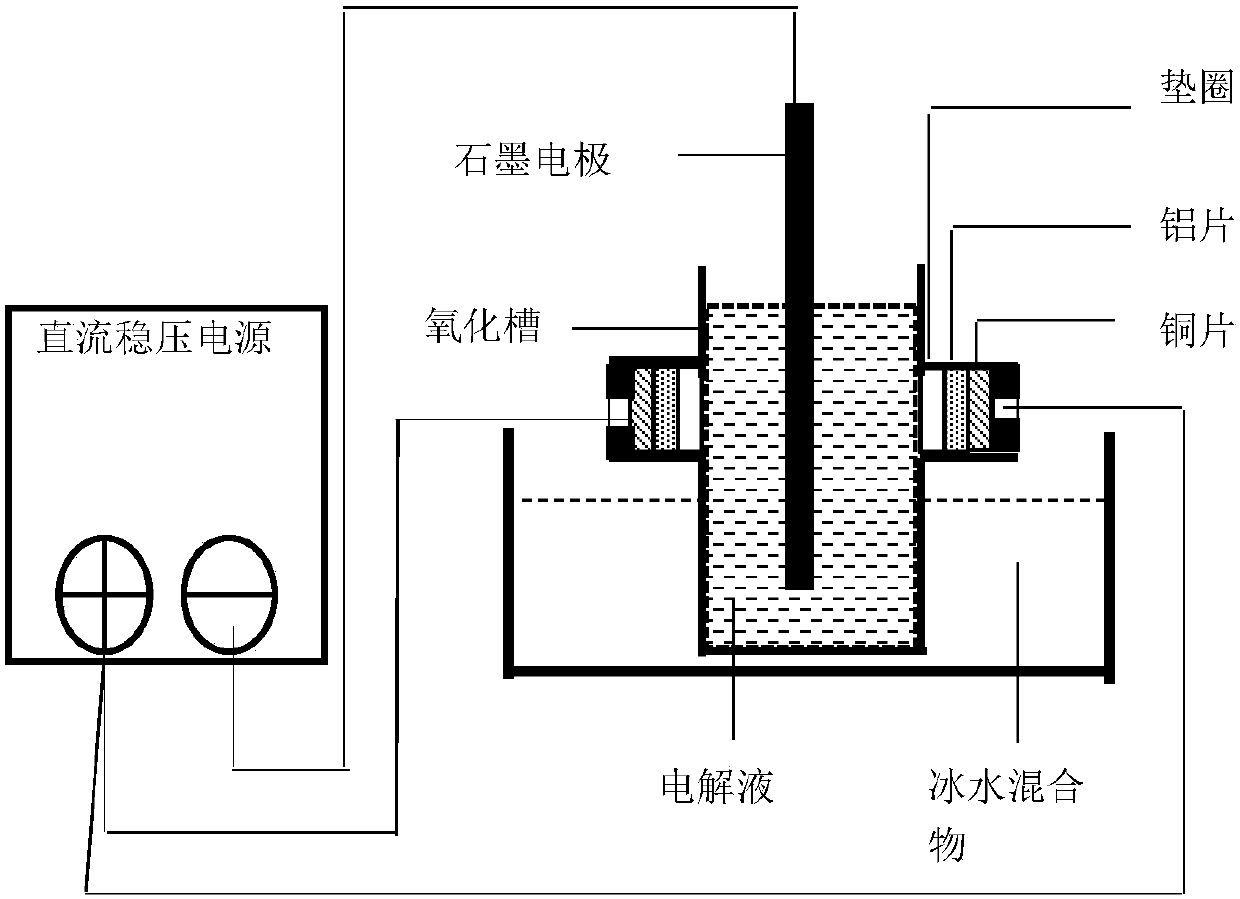

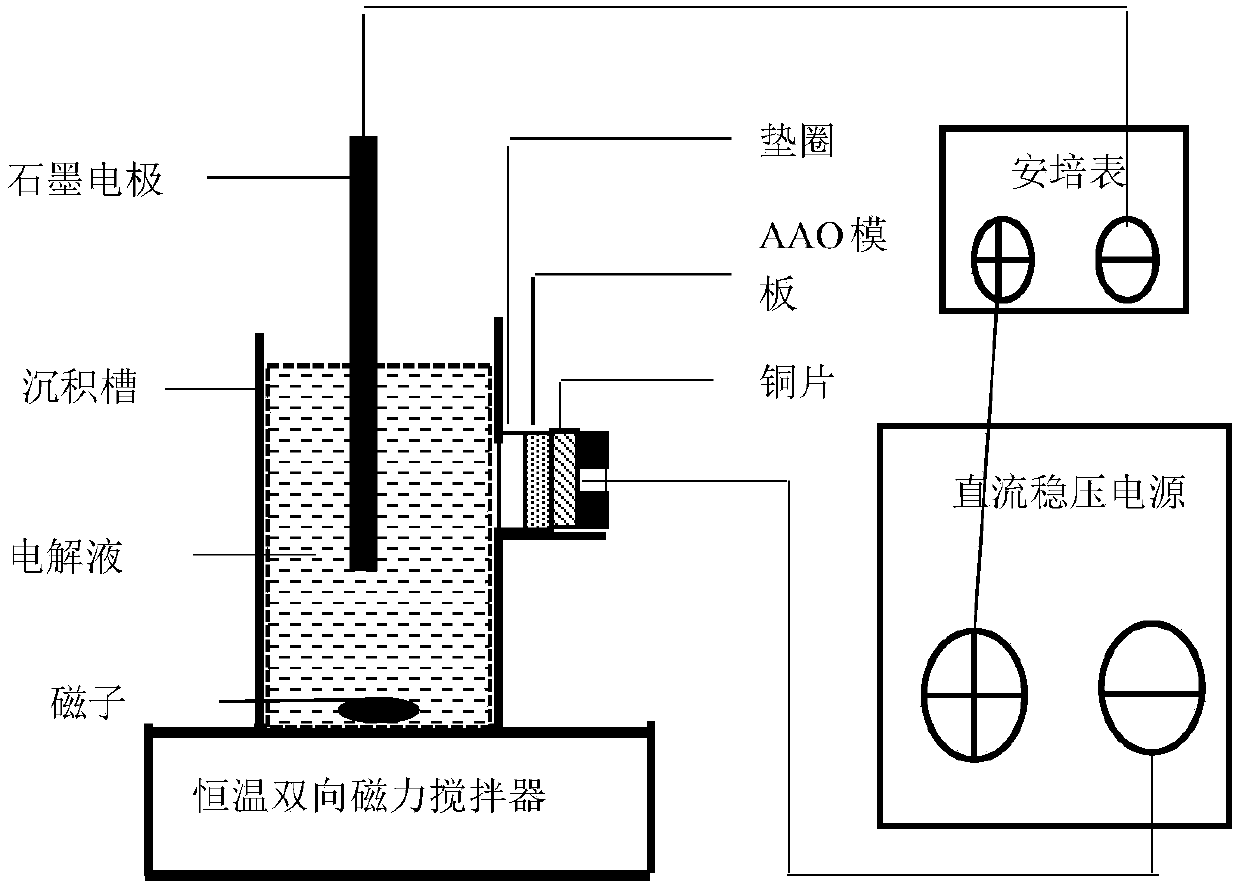

[0042] Step 1: Preparation of AAO template

[0043] In this paper, the AAO template method was used to prepare nanowires. The AAO template is prepared by secondary anodic oxidation in oxalic acid solution by using high-purity aluminum foil with a purity of 99.999% and a thickness of 0.3 mm. It mainly includes several processes of aluminum sheet pretreatment, secondary anodic oxidation, aluminum substrate removal, and hole expansion to remove barrier layer.

[0044] (1) Aluminum sheet pretreatment

[0045] Cutting: Cut the aluminum foil into a small disc with a diameter of 20mm, making it close to the diameter of the gasket used for oxidation.

[0046] Annealing: The aluminum sheet is then annealed in a vacuum tube furnace under the protection of an argon atmosphere. The annealing temperature is 500°C, and the annealing time is set to 5h. After the annealing is completed, it is cooled to room temperature with the furnace.

[0047] Washing: wash the aluminum sheet in acetone ...

Embodiment 2

[0065] Change the concentration of each component in Example 1 to C(NdCl 3 ·6H 2 O)=0.1mol / L, C(FeCl 2 4H 2 O)=0.35mol / L, C(CoCl 2 ·6H 2 O)=0.1mol / L, C(H 3 BO 3 )=0.48mol / L, C(C 2 h 5 NO 2 )=0.2mol / L, C(C 6 h 8 o 6 )=0.023mol / L, and others are all the same as in Example 1.

[0066] In this embodiment, the metal atomic ratio is Tb:Fe:Co=2:7:2, and the mass ratio is about 5:10:4.

Embodiment 3

[0068] Change the concentration of each component in Example 1 to C(NdCl 3 ·6H 2 O)=0.4mol / L, C(FeCl 2 4H 2 O)=0.35mol / L, C(CoCl 2 ·6H 2 O)=0.05mol / L, C(H 3 BO 3 )=0.48mol / L, C(C 2 h 5 NO 2 )=0.2mol / L, C(C 6 h 8 o 6 )=0.023mol / L, the deposition voltage was changed to 2V, the deposition time was changed to 1h, and the others were the same as in Example 1.

[0069] In this embodiment, the metal atomic ratio is Tb:Fe:Co=8:7:1, and the mass ratio is about 4:5:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com