Internal-circulation hot air dryer discharge chamber

A technology of hot air dryer and internal circulation, which is applied in drying, drying of solid materials, grain drying, etc. It can solve the problems of not considering the structure, restricting the promotion and use value, and high labor intensity, so as to reduce the probability of blockage , Vacuuming and impurity removal effect is good, and the effect of improving the drying progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

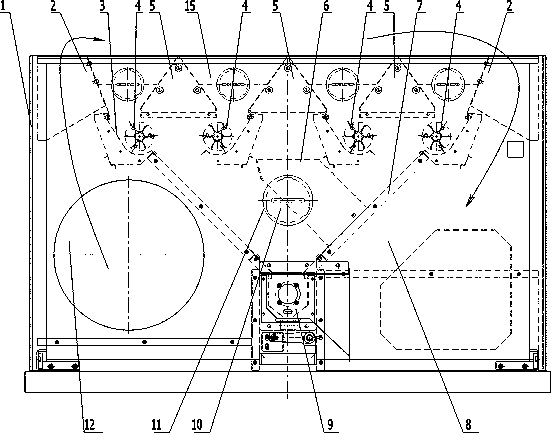

[0023] The discharge chamber of the internal circulation hot air dryer shown in the attached figure is the main part of the dryer, including the shell 1, the guide plate 2, the deflector 3, the discharge wheel 4, the diverter plate 5, and the air guide pipe 6 . The upper ends of the inner walls on the left and right sides are respectively provided with guide plates 2 with air ducts on the axial length of the opening of the rectangular box body; at least three groups of shunts in the shape of isosceles triangles are arranged equidistantly between the two guide plates 2 plate 5; the two ends of the diverter plate 5 are respectively fixed on the inner walls of the front and rear side plates of the housing 1, and the two groups of diverter plates 5 on the left and right sides are respectively provided with discharge wheels 4 below the two c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com