An impact-resistant composite material used for powdery paint and modified powdery paint

A technology for powder coatings and composite materials, applied in the field of impact-resistant composite materials for powder coatings and modified powder coatings, can solve the problems of coating breakage, poor mechanical properties, instability, etc., and achieves high alkyl content and short molecular chains. , The effect of good powder dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment and

[0026] Embodiment and comparative example:

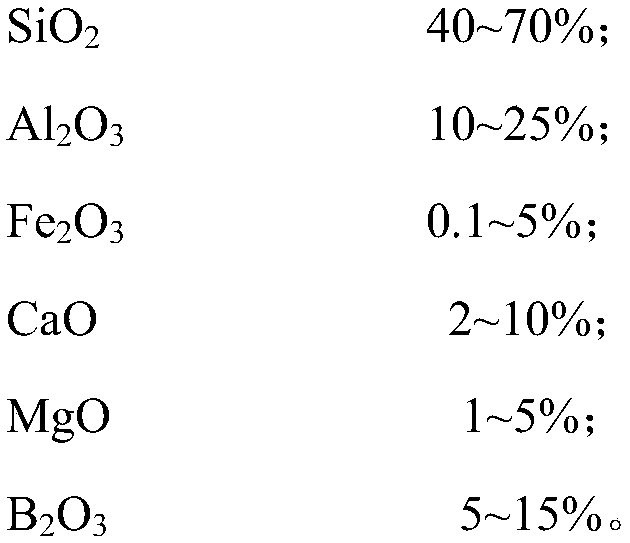

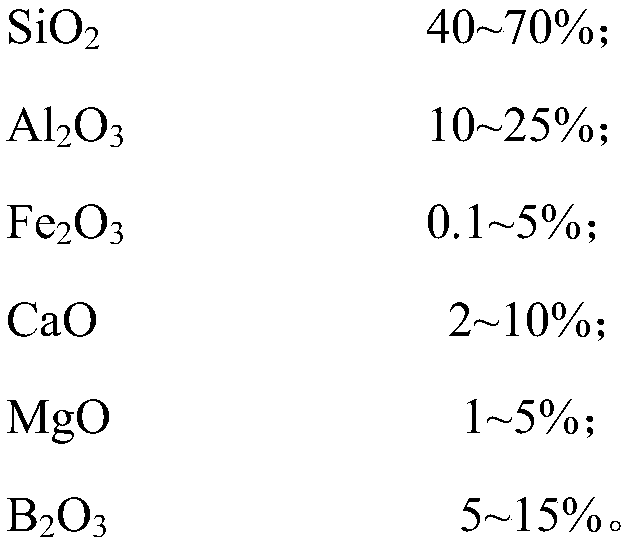

[0027] 61% SiO 2 , 17% Al 2 o 3 , 1% Fe 2 o 3 , 8% CaO, 3% MgO, 10% B 2 o 3 After compounding, it is melted at 1200°C, cooled, and then ball milled and classified to obtain inorganic fillers with different particle sizes.

[0028] Heat the inorganic filler to 75°C, add the first silane, raise the temperature to 100°C and keep it for 20 minutes, then add the second silane, and keep it at 100°C for 20 minutes to prepare the impact-resistant composite material.

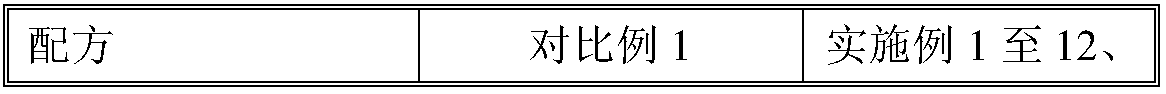

[0029] Prepare the powder coating according to the formula in Table 1. The preparation method is to mix and stir the raw materials for 20 minutes, extrude through a twin-screw extruder, cool and press into tablets, and classify. Among them, Comparative Example 1 is a conventional formula, Examples 1 to 12, and Comparative Examples 2 to 11 are modified powder coatings that use impact-resistant composite materials to replace part of barium sulfate. The formulations of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com