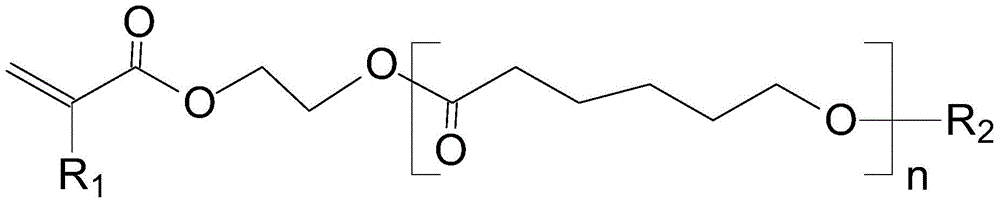

Adhesion promoter for radiation-cured coatings and preparation method thereof

An adhesion promoter and radiation curing technology, applied in chemical instruments and methods, preparation of organic compounds, preparation of carboxylate, etc., can solve the problems of poor adhesion fastness, large curing shrinkage, and poor flexibility of coatings , to achieve the effects of strong controllability of molecular segments and molecular weight, enhanced adhesion fastness, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

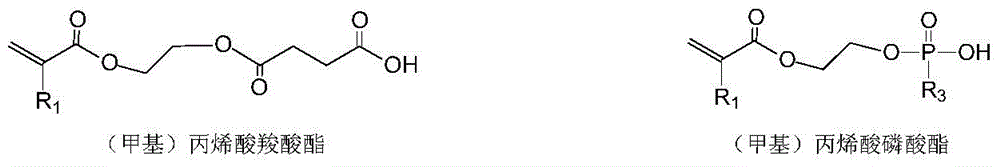

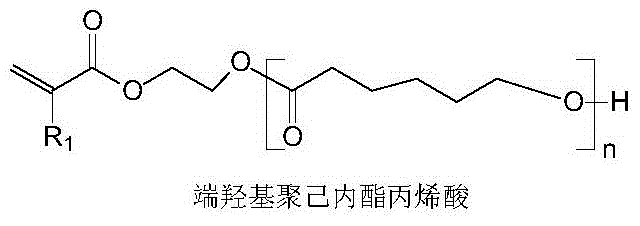

[0036] Add 116g of hydroxyethyl acrylate, 0.6g of butyl titanate, 0.3g of hydroquinone, 114g of ε-caprolactone (n=1) into the reaction flask equipped with cooling reflux, heating device, thermometer and stirring, and start Stir and heat, raise the temperature to 140°C, stir and react for 8 hours; after that, cool down to below 80°C, slowly add 90g of succinic anhydride, after stirring and dissolving completely, raise the temperature to 120°C, and keep it warm for 6h; after the reaction, cool down to 60°C, After hot filtration, the radiation-cured adhesion promoter (theoretical n value=1) was obtained as a colorless viscous liquid with a viscosity (25° C.) of about 18000 mPa·s.

[0037] The UV curing light of 50 parts of aliphatic polyurethane acrylate with a molecular weight (Mw) of about 2200, 30 parts of 1,6-hexanediol diacrylate, 17 parts of trimethylolpropane triacrylate, and 3 parts of UV initiator In the oil batching, introduce the adhesion promoter described in 5% of th...

Embodiment 2

[0039] Add 116g of hydroxyethyl acrylate, 0.6g of butyl titanate, 0.3g of hydroquinone, 228g of ε-caprolactone (n=2) into the reaction flask equipped with cooling reflux, heating device, thermometer and stirring, and start Stir and heat, raise the temperature to 140°C, stir and react for 8 hours; after that, cool down to below 80°C, slowly add 90g of succinic anhydride, after stirring and dissolving completely, raise the temperature to 120°C, and keep it warm for 6h; after the reaction, cool down to 60°C, After hot filtration, the radiation-cured adhesion promoter (theoretical n value=2) was obtained as a colorless viscous liquid with a viscosity (25° C.) of about 16000 mPa·s.

[0040] The UV curing light of 50 parts of aliphatic polyurethane acrylate with a molecular weight (Mw) of about 2200, 30 parts of 1,6-hexanediol diacrylate, 17 parts of trimethylolpropane triacrylate, and 3 parts of UV initiator In the oil ingredients, 5% of the total amount of the varnish formula was ...

Embodiment 3

[0042] Add 130g of hydroxyethyl methacrylate, 0.6g of monobutyl tin oxide, 0.3g of 4-methoxyphenol, 228g of ε-caprolactone in the reaction flask equipped with cooling reflux, heating device, thermometer and stirring (n =2), start stirring and heating, heat up to 180°C, stir and react for 2h; after that, cool down to below 80°C, slowly add 90g of succinic anhydride, after stirring and dissolving completely, raise the temperature to 140°C, keep warm for 2h; after the reaction, Cool down to 60°C and heat filter to obtain the radiation curing adhesion promoter (theoretical n value=2), light yellow viscous liquid with a viscosity (25°C) of about 16000 mPa·s.

[0043] The radiation-cured adhesion promoter described in Example 3 was tested with the same formula as in Example 1, and the test results were basically consistent with Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com