A kind of high-gloss high-black spray-free pc/pet alloy resin and preparation method thereof

A technology of alloy resin and high-speed mixer, which is applied in the field of polymer materials, can solve problems such as the inability to achieve spray-free effects, high blackness requirements, and insufficient gloss, and achieve good wear resistance, reduce spraying costs, and toughness Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

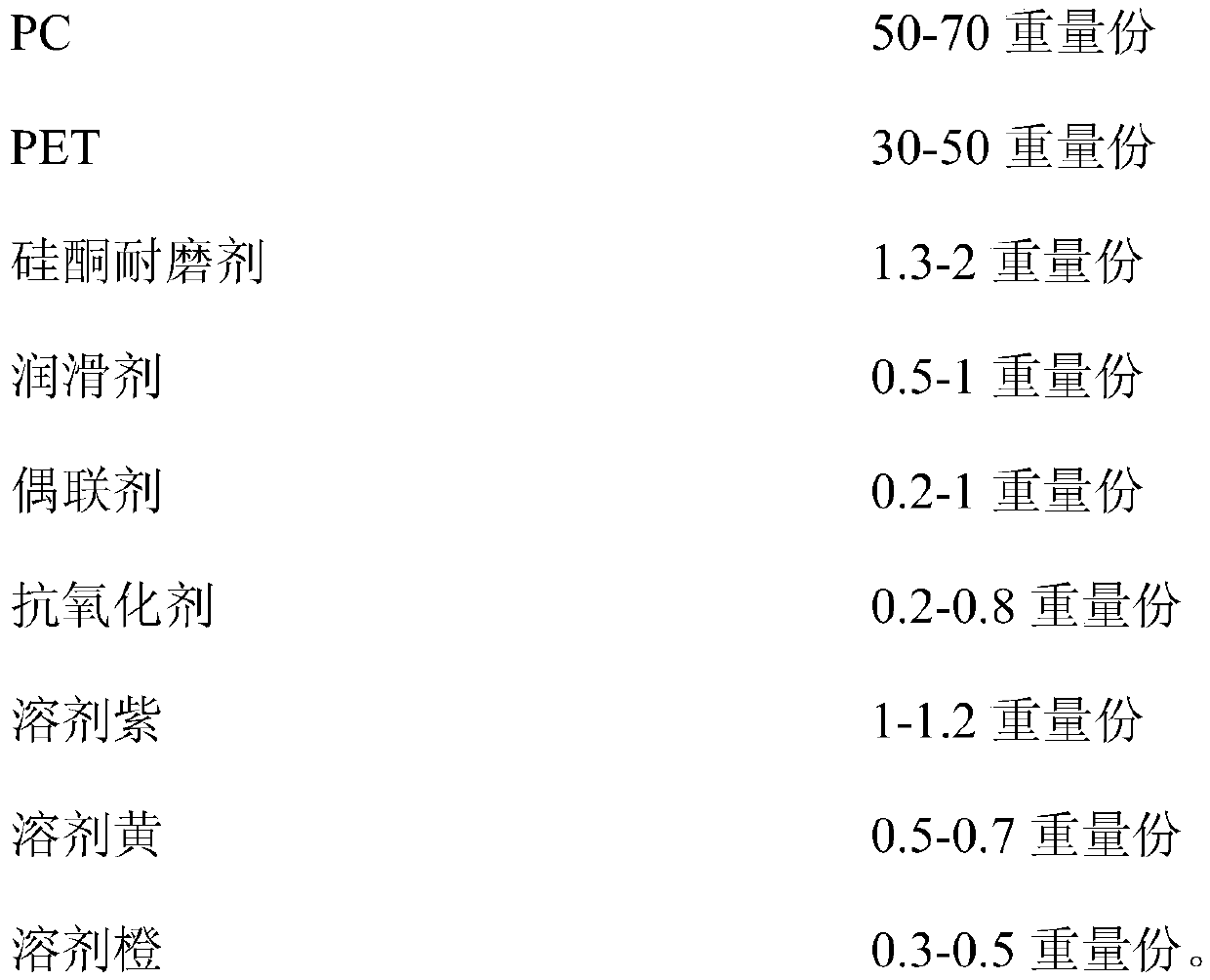

[0051] The raw materials for preparing the PC / PET alloy resin provided in this embodiment include the following components:

[0052]

[0053] The preparation method is as follows:

[0054] (1) Mix PC, PET, silicone anti-wear agent, lubricant, coupling agent and antioxidant in a high-speed mixer for 4 minutes.

[0055] (2) Add Solvent Violet, Solvent Yellow and Solvent Orange to the mixture obtained in step (1), mix in a high-speed mixer for 4.5 minutes, use a twin-screw extruder to melt for 2 minutes, extrude and pellet to obtain the PC / PET alloy resin; the temperature of the twin-screw extruder is designed as: 230°C in the first zone, 240°C in the second zone, 250°C in the third zone, 260°C in the fourth zone, and 260°C in the fifth zone. The temperature in the six zone is 260℃, the temperature in the seven zone is 260℃, the temperature in the eight zone is 260℃, the temperature in the nine zone is 260℃, the temperature in the ten zone is 270℃, the screw speed is 500r / min, and the ...

Embodiment 2

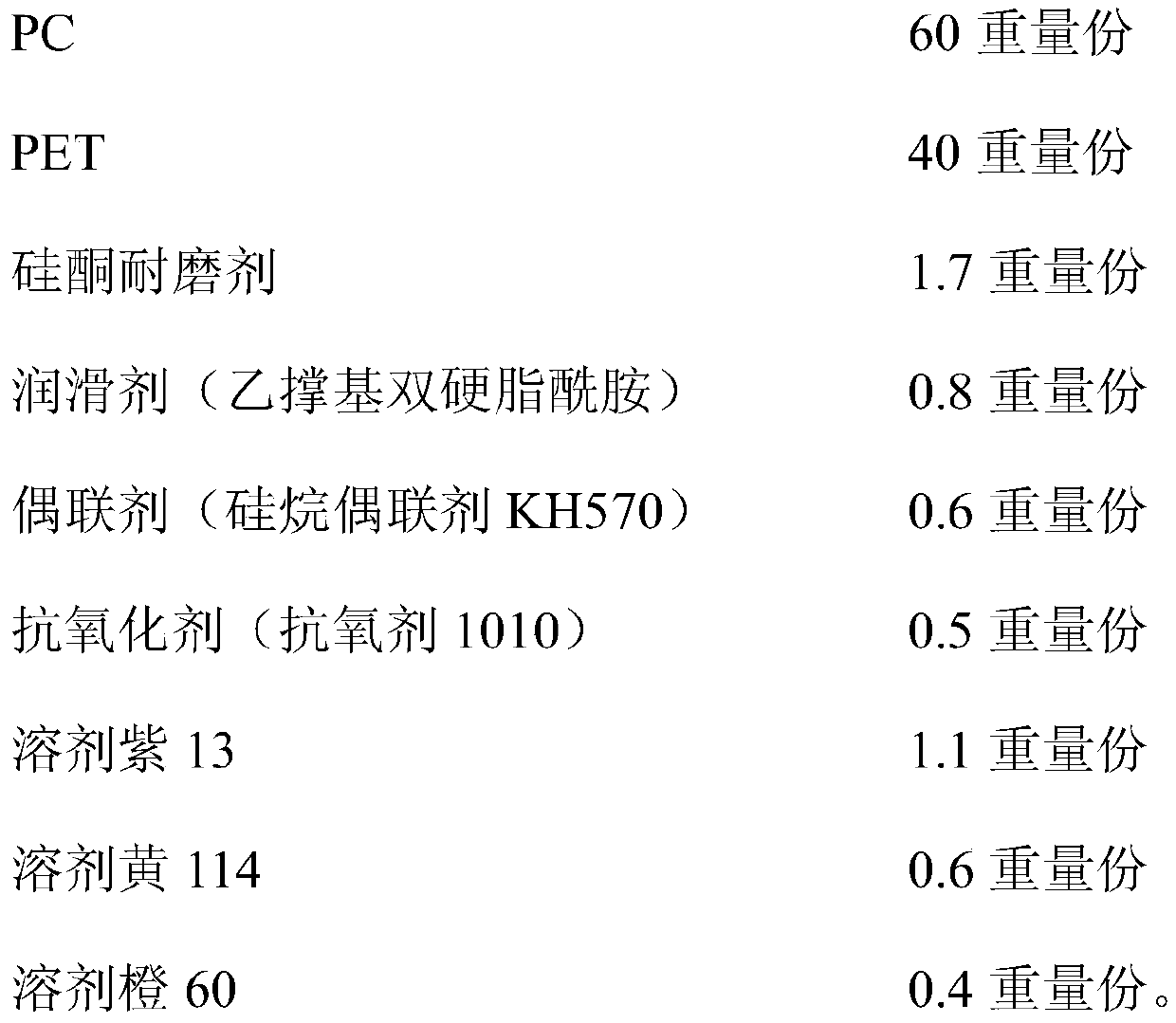

[0057] The raw materials for preparing the PC / PET alloy resin provided in this embodiment include the following components:

[0058]

[0059]

[0060] The preparation method is as follows:

[0061] (1) Mix PC, PET, silicone anti-wear agent, lubricant, coupling agent and antioxidant in a high-speed mixer for 3 minutes.

[0062] (2) Add Solvent Violet, Solvent Yellow and Solvent Orange to the mixture obtained in step (1), mix in a high-speed mixer for 5 minutes, use a twin-screw extruder to melt for 1 minute, extrude and pelletize to obtain the PC / PET alloy resin; the temperature design of the twin-screw extruder is: zone one is 225℃, zone two is 235℃, zone three is 245℃, zone four is 255℃, zone five is 255℃, six Zone temperature is 255℃, zone seven temperature is 255℃, zone eight temperature is 255℃, zone nine temperature is 255℃, zone ten temperature is 265℃, screw speed is 450r / min, vacuum degree of twin screw extruder is working It is 0.12MPa.

Embodiment 3

[0064] The raw materials for preparing the PC / PET alloy resin provided in this embodiment include the following components:

[0065]

[0066]

[0067] The preparation method is as follows:

[0068] (1) Mix PC, PET, silicone anti-wear agent, lubricant, coupling agent and antioxidant in a high-speed mixer for 5 minutes.

[0069] (2) Add Solvent Violet, Solvent Yellow and Solvent Orange to the mixture obtained in step (1), mix in a high-speed mixer for 4 minutes, use a twin-screw extruder to melt for 3 minutes, extrude and pelletize to obtain the PC / PET alloy resin; the temperature design of the twin-screw extruder is: zone one is 235℃, zone two is 245℃, zone three is 255℃, zone four is 265℃, zone five is 265℃, six The temperature in zone is 265℃, the temperature in zone seven is 265℃, the temperature in zone eight is 265℃, the temperature in zone nine is 265℃, the temperature in zone ten is 275℃, the screw speed is 550r / min, the vacuum degree of twin screw extruder is working It is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com