Shaft pipe outer wall polishing device

A shaft tube and elastic device technology, which is applied in the direction of grinding machines, abrasive belt grinders, grinding racks, etc., can solve the problems of not meeting the needs of enterprises, poor grinding effect, and low efficiency, so as to meet the needs of use and improve the grinding effect. Good, the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

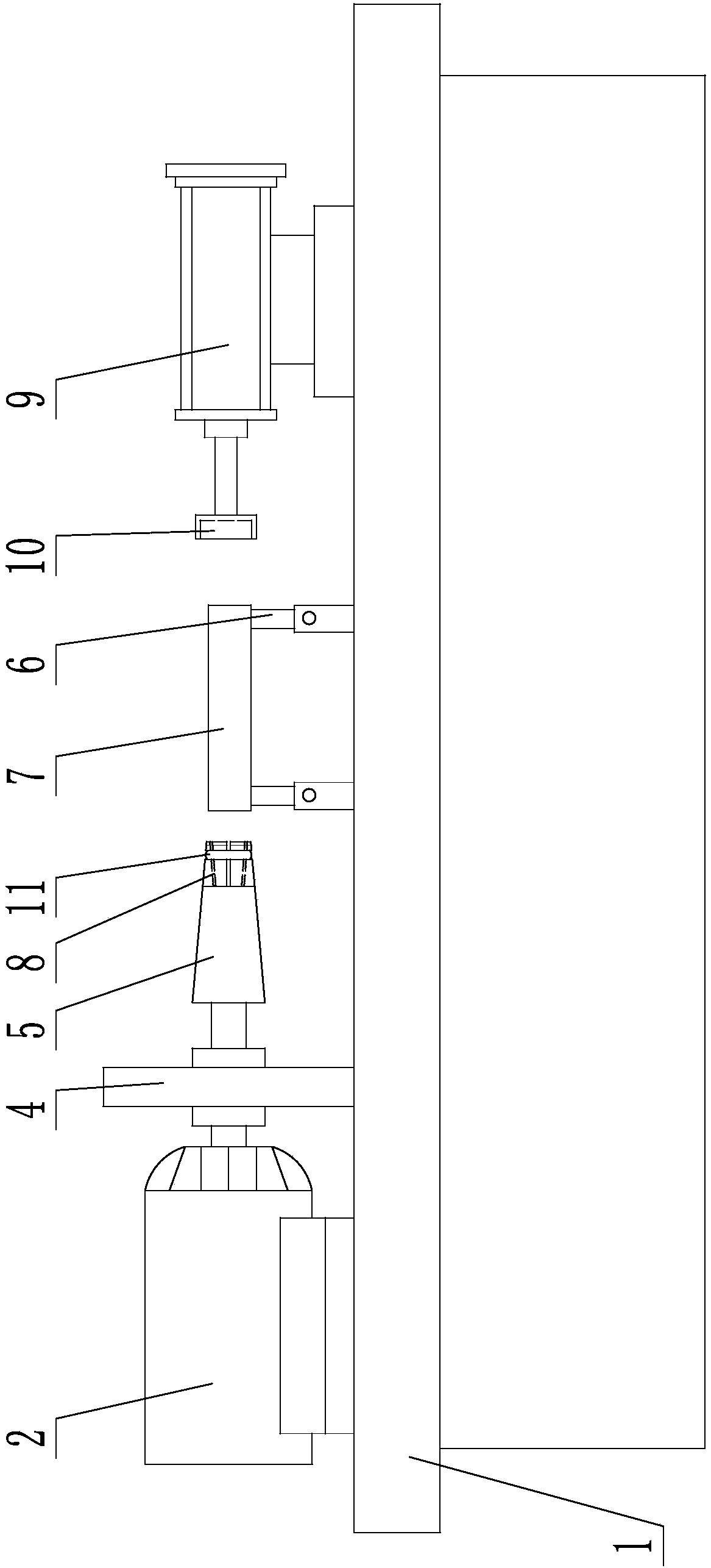

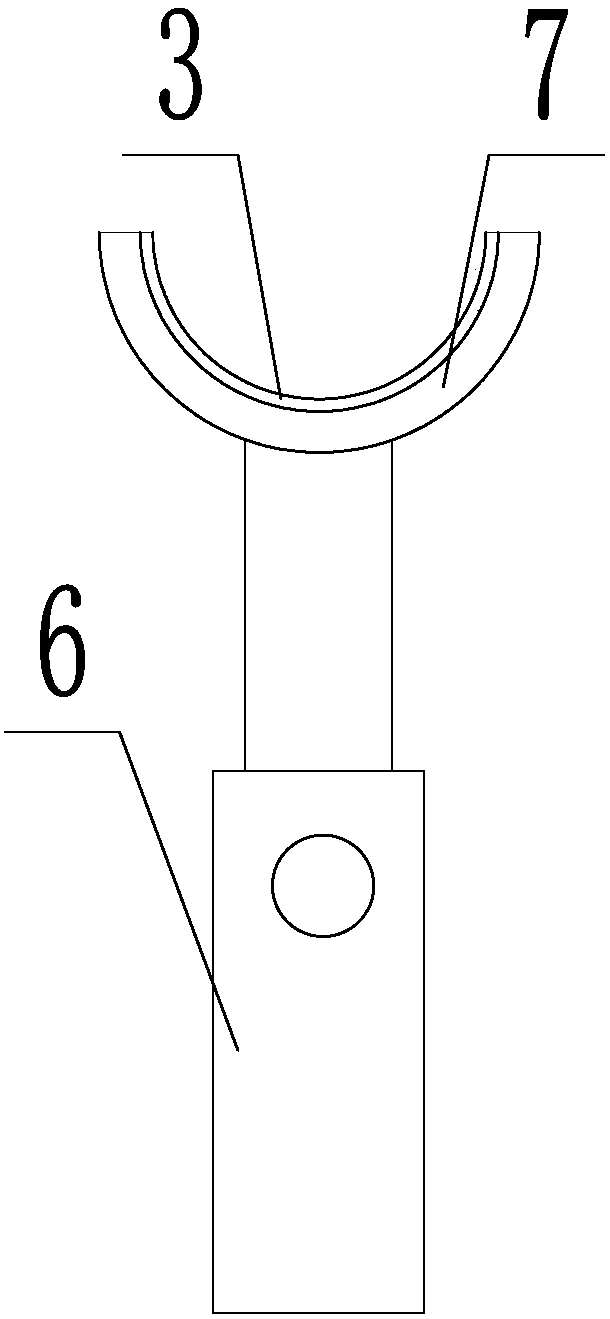

[0013] Such as figure 1 , 2 As shown, the present invention comprises base 1, motor 2 and gauze belt 3, is characterized in that, the upper side of described base 1 is fixed with motor 2, and the output shaft of described motor 2 runs through fixed plate 4 and connects with tapered sleeve 5 connection, the upper middle position of the base 1 is provided with an arc-shaped sleeve 7 connected by a telescopic column 6, the inner wall of the arc-shaped sleeve 7 is provided with a gauze belt 8, and the right side of the upper part of the base 1 is provided with a propulsion cylinder 9 , One end of the propulsion cylinder 9 is provided with a placement groove 10 .

[0014] One end of the tapered sleeve 5 is evenly divided into two parts, and an elastic device 11 is arranged on the outer wall of the tapered sleeve 5 .

[0015] The diameter of the inner wall of the tapered sleeve 5 gradually decreases from the right end to the left end.

[0016] An anti-slip rubber pad 8 is also pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com