Preparation and application of hierarchical pore metal-organic framework loaded heteropolyacid catalyst

A technology of supporting heteropolyacids and organic frameworks, applied in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, refining with oxygenated compounds, etc. It can achieve the effect of high oxidative desulfurization activity and photocatalytic degradation of dyes, high crystalline skeleton structure, and simple synthesis method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Preparation of hierarchical pore structure POMs@HKUST-1 catalyst: Weigh 0.7g of trimesic acid and 0.12g of cetyltrimethylammonium bromide, dissolve them in 16mL of ethanol solution for later use. Weigh 1.45g copper nitrate trihydrate and 1.02g phosphotungstic acid, dissolve in 12mL deionized water, mix the two solutions, and stir vigorously for 30min. The mixture was poured into a reaction kettle and placed at 120°C for 12 hours of crystallization. Cool to room temperature, filter with suction, and rinse with deionized water. Rinse the product with 50ml of ethanol solution, put it into a 100ml Erlenmeyer flask, reflux at 85°C for 4h, then suction filter, and wash with ethanol solution. Repeat the previous step three times, put it in an oven at 120°C and dry it for 10 hours, and obtain the dark blue composite material POMs@HKUST-1.

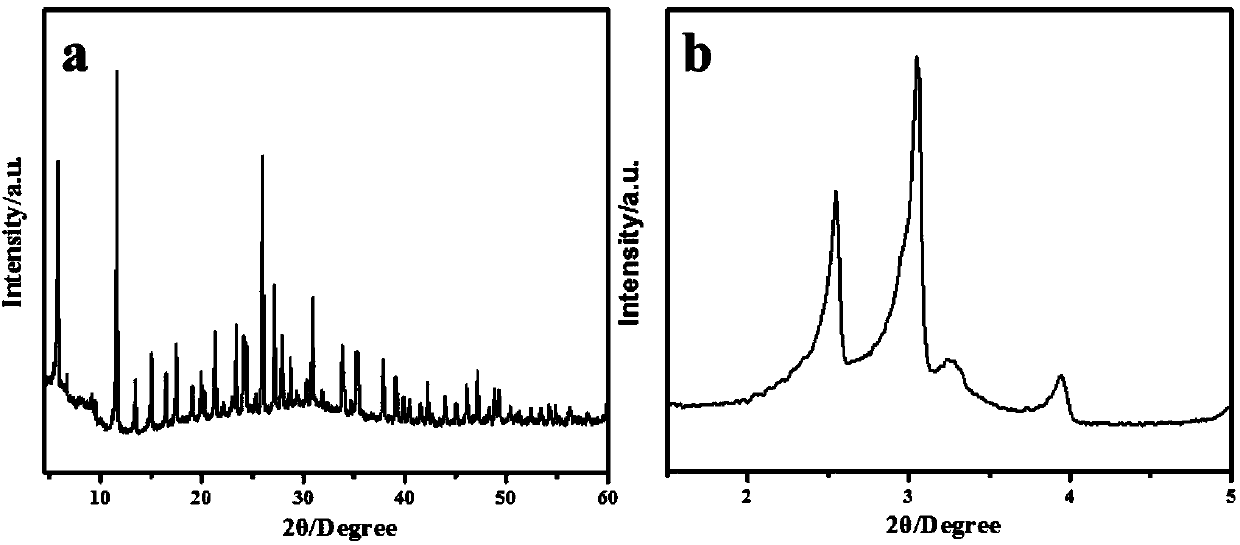

[0046] The resulting product was characterized by XRD, figure 1 (a) is the wide-angle XRD pattern of the sample between 5-60°. It can be...

Embodiment 2

[0050] Preparation of hierarchical pore structure POMs@HKUST-1 catalyst: Weigh 0.84g of trimesic acid and 0.18g of cetyltrimethylammonium bromide, dissolve them in 16mL of ethanol solution for later use. Weigh 1.21g copper nitrate trihydrate and 1.44g phosphotungstic acid, dissolve in 12mL deionized water, mix the two solutions, and stir vigorously for 30min. The mixture was poured into a reaction kettle and placed at 120°C for 12 hours of crystallization. Cool to room temperature, filter with suction, and rinse with deionized water. Rinse the product with 50ml of ethanol solution, put it into a 100ml Erlenmeyer flask, reflux at 85°C for 4h, then suction filter, and wash with ethanol solution. Repeat the previous step three times, put it in an oven at 120°C and dry it for 10 hours, and obtain the dark blue composite material POMs@HKUST-1.

Embodiment 3

[0052] Preparation of hierarchical pore structure POMs@HKUST-1 catalyst: Weigh 1.37g of trimesic acid and 1.27g of cetyltrimethylammonium bromide, dissolve them in 16mL of ethanol solution for later use. Weigh 2.17g of copper nitrate trihydrate and 1.44g of phosphotungstic acid, dissolve them in 12mL of deionized water, mix the two solutions, and stir vigorously for 30min. The mixture was poured into a reaction kettle and placed at 120°C for 12 hours of crystallization. Cool to room temperature, filter with suction, and rinse with deionized water. Rinse the product with 50ml of ethanol solution, put it into a 100ml Erlenmeyer flask, reflux at 85°C for 4h, then suction filter, and wash with ethanol solution. Repeat the previous step three times, put it in an oven at 120°C and dry it for 10 hours, and obtain the dark blue composite material POMs@HKUST-1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com