Fixing device and fixing method for seed crystal or substrate in single crystal growth of aluminum nitride

A technology of fixing device and fixing method, which is applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve problems such as aluminum nitride single crystal failure, achieve good migration ability, avoid unfavorable factors, and solve the problem of seed crystal fixing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

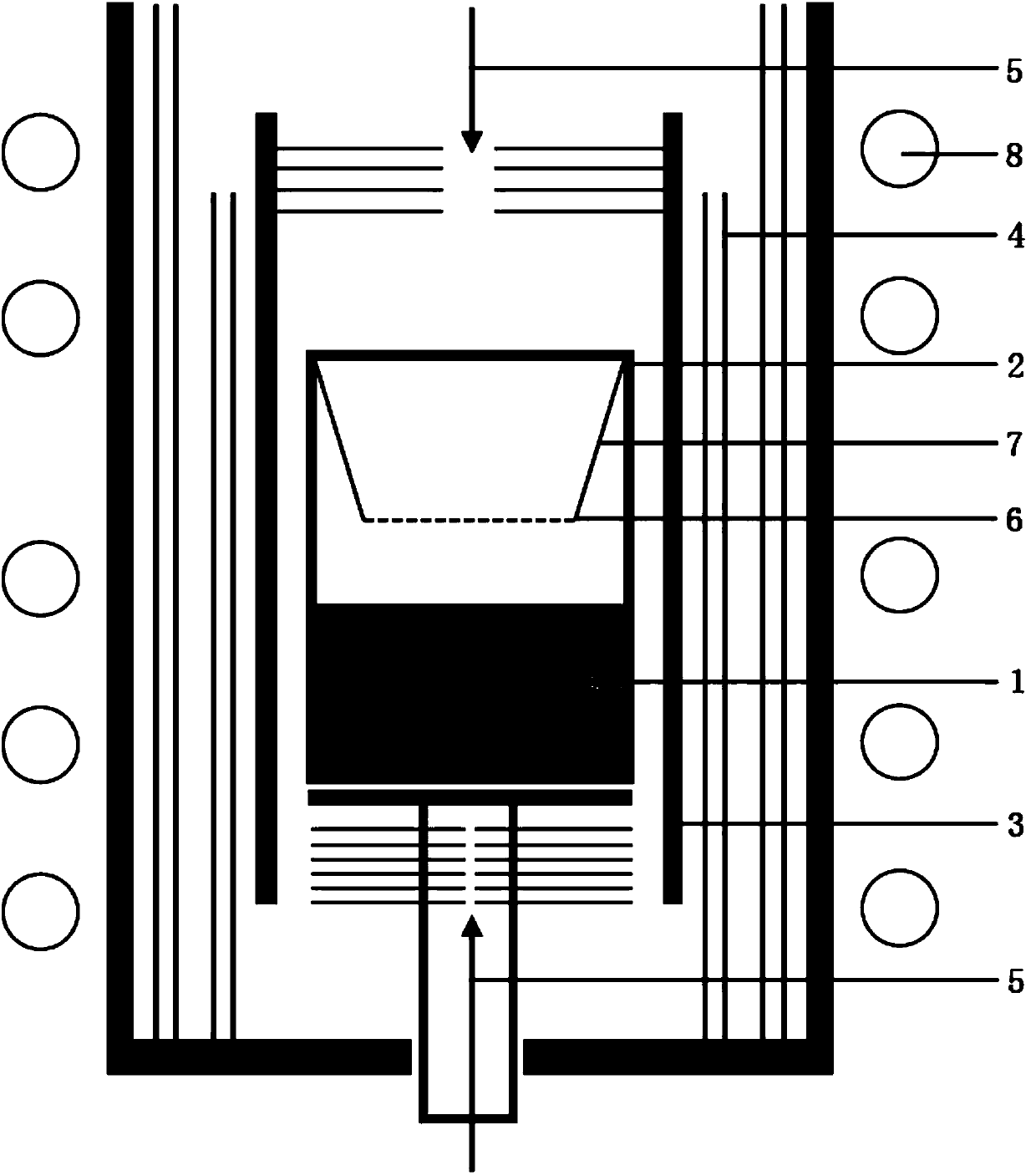

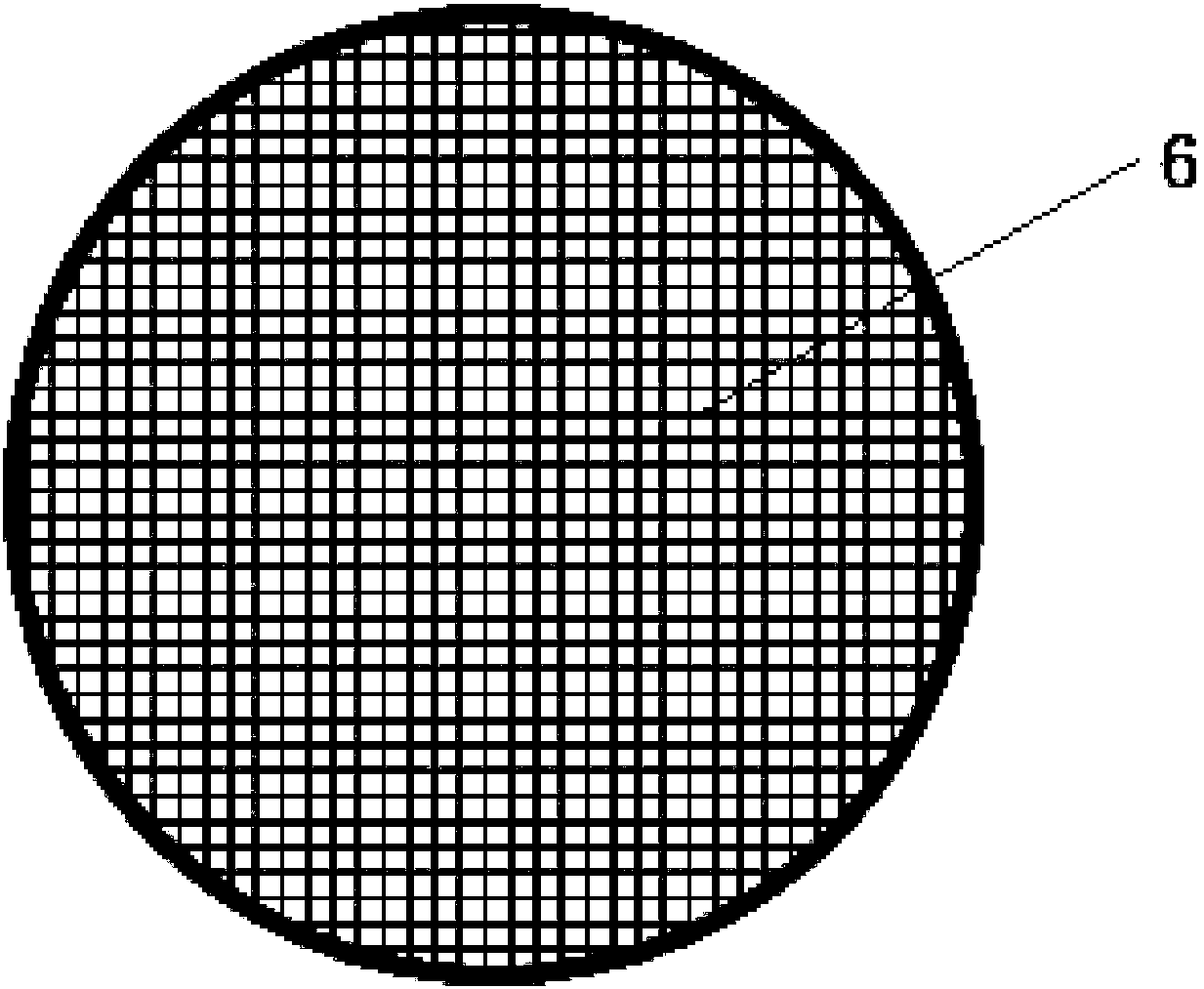

[0059] Put the aluminum nitride powder source 1 into the crucible 2, fix the high-purity tungsten wire mesh at 10 mm above the aluminum nitride powder source 1 through the fixing rod 7, close the crucible cover, and place the crucible 2 in the crystal growth equipment;

[0060] Adjust the air pressure to 100kPa, rapidly raise the temperature to 1800°C and then slowly raise the temperature to 2200°C;

[0061] Adjust the air pressure to 50kPa, and start the adjustment mechanism to adjust the height of the crucible 2 according to the data fed back by the temperature measuring mechanism 5, so that the temperature gradient therein reaches 10°C / cm;

[0062] Keep warm for 80 hours;

[0063] Adjust the air pressure to 100kPa, slowly cool down to room temperature, open the crucible lid and collect aluminum nitride crystals from the high-purity tungsten wire mesh.

Embodiment 2

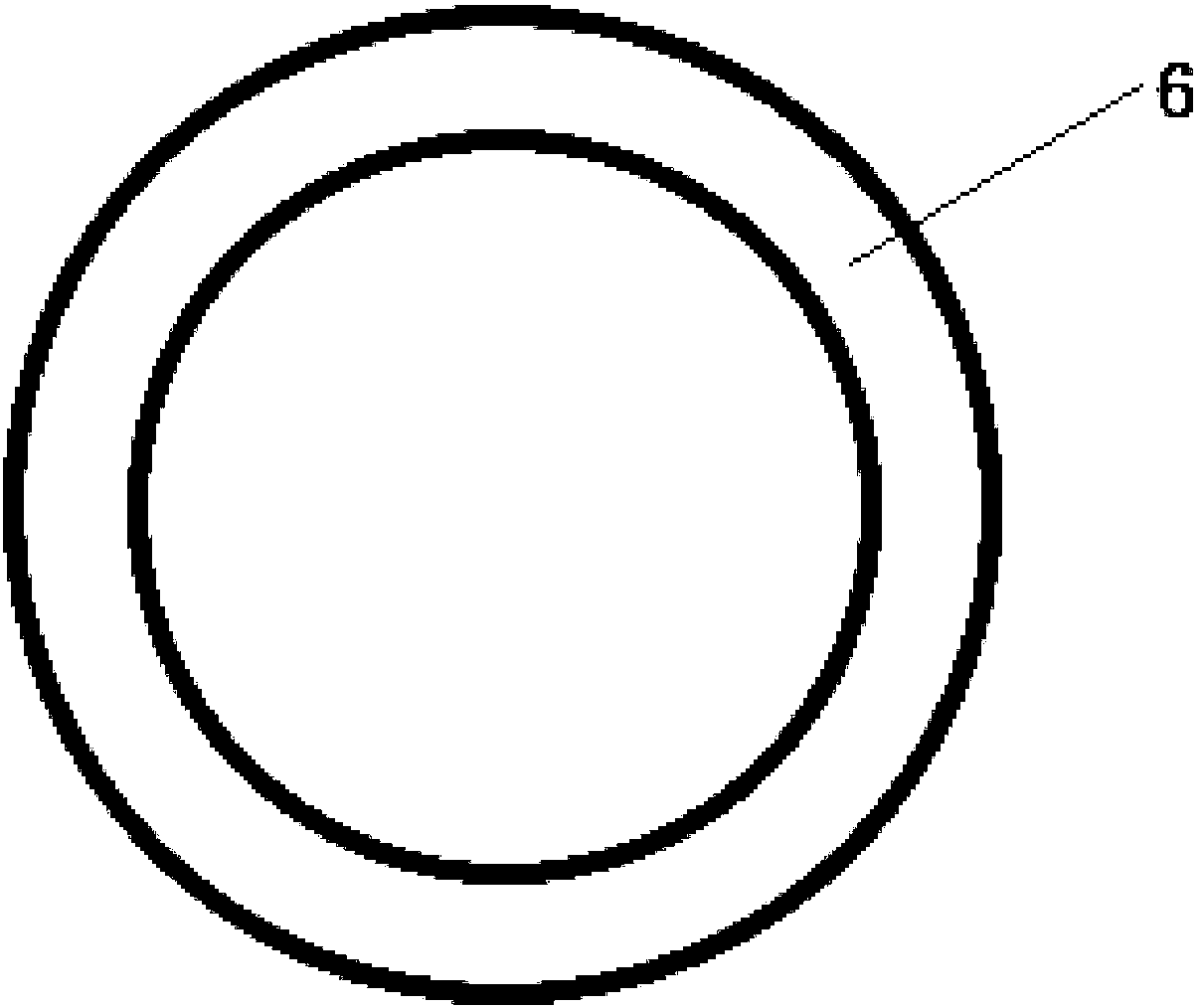

[0065] Put the aluminum nitride powder source 1 into the crucible 2, place the aluminum nitride seed crystal on the growth platform 6 in the shape of a hollow ring, and fix it at 5 mm above the aluminum nitride powder source 1 by a fixing rod 7, Close the crucible lid, and place the crucible 2 in the crystal growth equipment;

[0066] Adjust the air pressure to 120kPa, quickly raise the temperature to 1800°C and then slowly raise the temperature to 2200°C;

[0067] Adjust the air pressure to 80kPa, and start the adjustment mechanism to adjust the height of the crucible 2 according to the data fed back by the temperature measuring mechanism 5, so that the temperature gradient therein reaches 20°C / cm;

[0068] Keep warm for 100 hours;

[0069] Adjust the air pressure to 120kPa, slowly cool down to room temperature, open the crucible lid and collect aluminum nitride crystals from the aluminum nitride seed crystals.

Embodiment 3

[0071] Put the aluminum nitride powder source 1 into the crucible 2, install the silicon carbide substrate on the growth platform 6 with a buckle structure, fix it at 20 mm above the aluminum nitride powder source 1 through the fixing rod 7, and close the crucible cover, and place the crucible 2 in the crystal growth equipment;

[0072] Adjust the air pressure to 80kPa, quickly raise the temperature to 1800°C and then slowly raise the temperature to 1850°C;

[0073] Adjust the air pressure to 30kPa, and start the adjustment mechanism to adjust the height of the crucible 2 according to the data fed back by the temperature measuring mechanism 5, so that the temperature gradient therein reaches 5°C / cm;

[0074] Keep warm for 60 hours;

[0075] Adjust the air pressure to 80kPa, slowly cool down to room temperature, open the crucible lid and collect aluminum nitride crystals from the silicon carbide substrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com