Real-time monitoring system for electrified detachable current collecting device of generator

A technology for real-time monitoring and current collectors, applied in electromechanical devices, current collectors, rotating current collectors, etc., can solve the problems of current and carbon brush temperature monitoring, brush holder temperature rise, and poor contact The box and the brush holder are stable, the contact area is increased, and the current distribution is uniform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

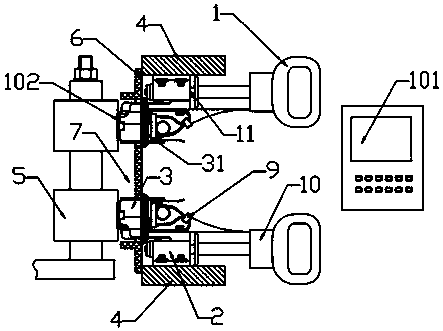

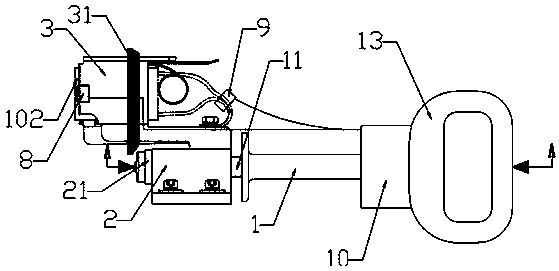

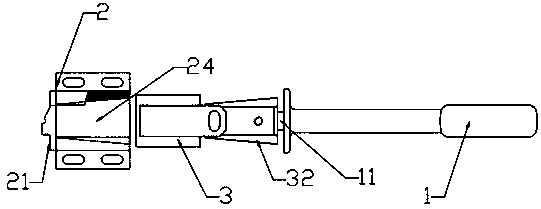

[0028] This embodiment provides a real-time monitoring system for a live generator detachable collector device, specifically, as figure 1 , figure 2 , Figure 4 As shown, the brush holder assembly includes a brush box 3, a brush seat 2 and a brush holder handle 1, the brush holder handle 1 is fixedly connected with the brush box 3, and a carbon brush 102 is arranged in the brush box 3, and the brush handle One end of the handle 1 is provided with a rotating shaft 11 sleeved in the brush holder 2, a rotating pin 12 is provided radially at the end of the rotating shaft 11, and an outwardly protruding pin is provided at the end of the brush holder 2 facing the collector ring 5 of the generator. And the locking sleeve 21 that is circular; On the locking sleeve 21, be provided with two center symmetrical slopes 22, by rotating the brush grip handle 1, the revolving pin 12 can be driven to move from the low end of the slope 22 to the high end, so that The revolving pin 12 is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com