Method for preparing functional cellulose capable of increasing effective content of functional materials

A technology of functional substances and effective content, applied in the direction of artificial filaments made of viscose, can solve the problems of serious loss of functional materials, high interfacial energy, influence of fiber mechanical properties, etc., and achieve remarkable functional effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

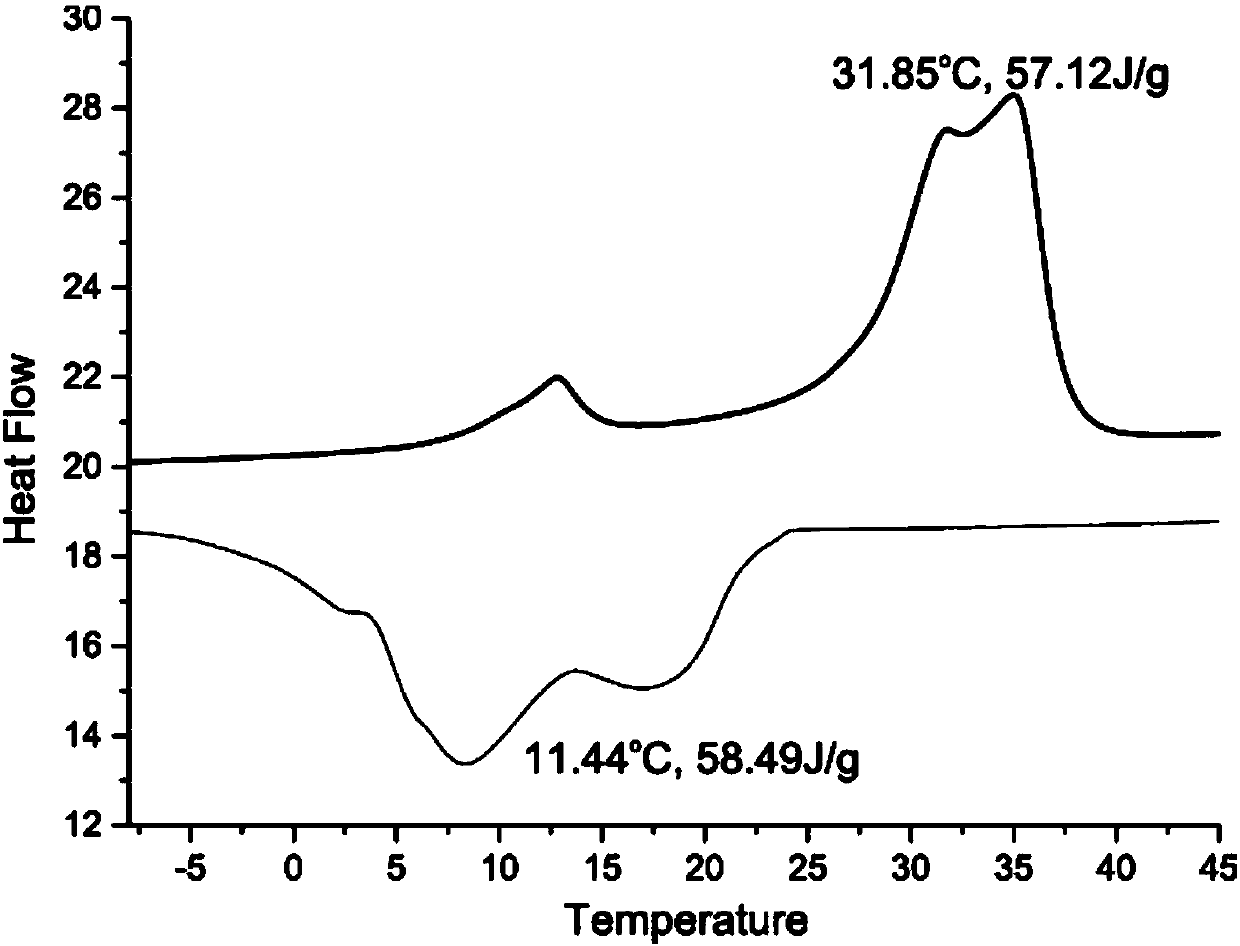

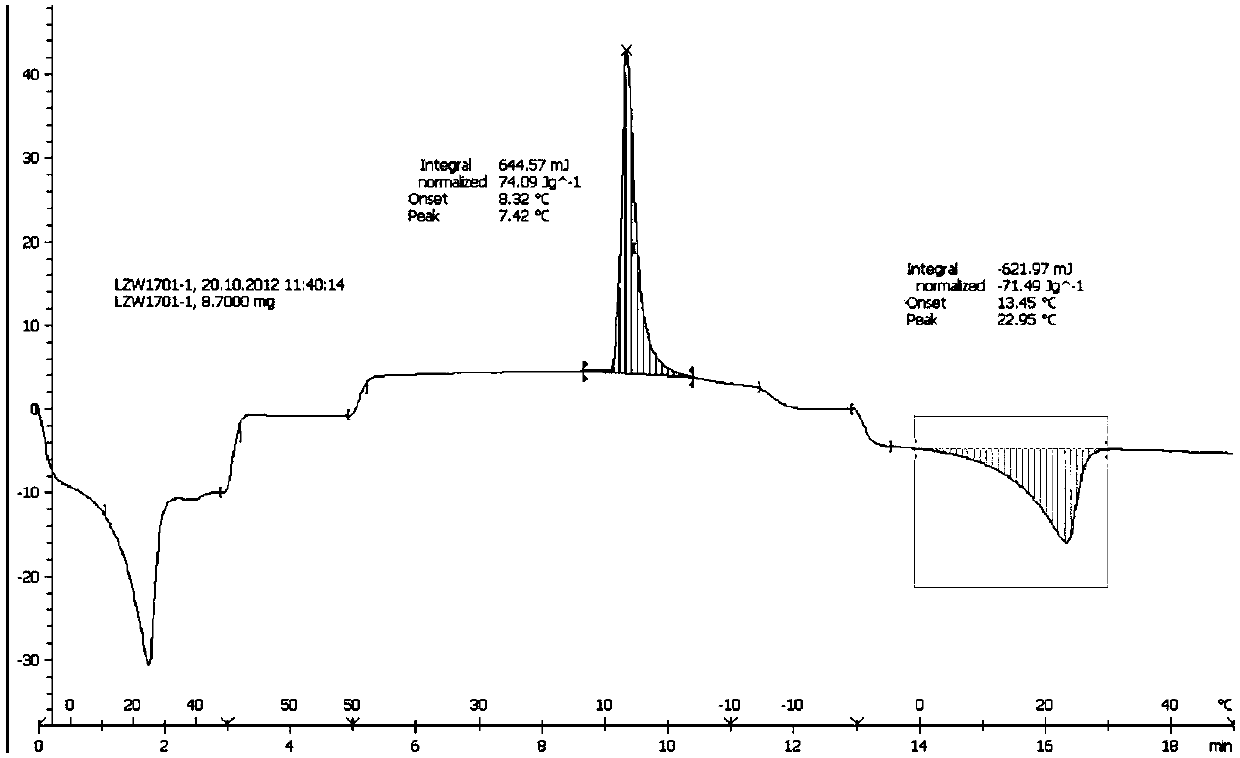

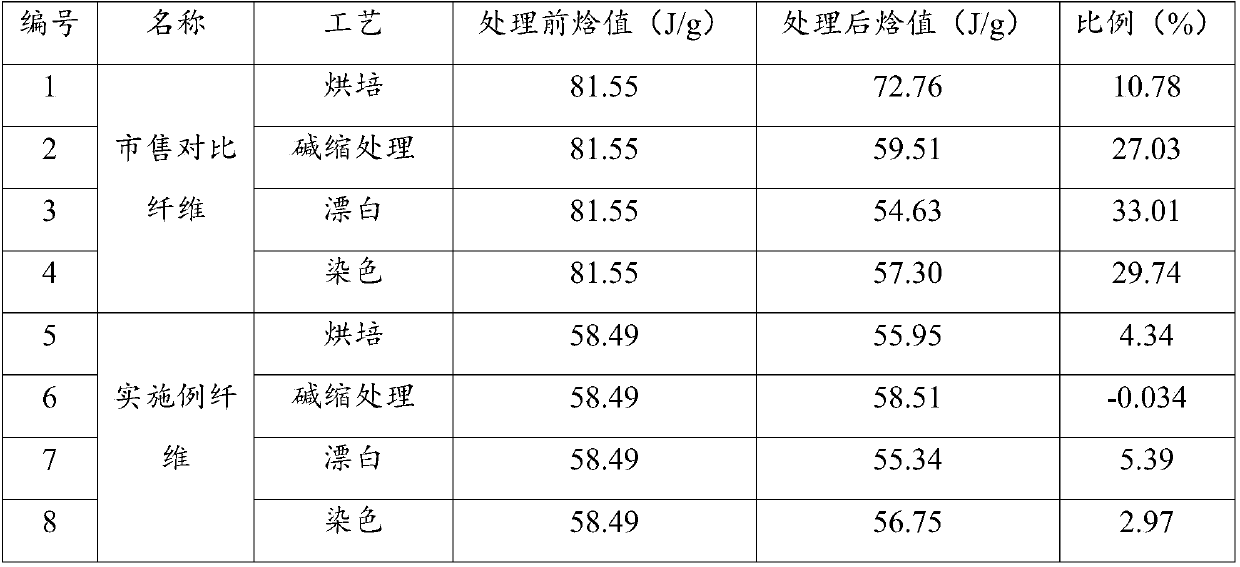

Embodiment 1

[0048] A regenerated cellulose filament that increases the effective content of phase change materials is prepared by the following method:

[0049] 1) By dissolving cellulose with a degree of polymerization of 650 in an aqueous solution containing 6.15% sodium hydroxide and 8% zinc oxide by mass ratio, freezing it below -5°C, and then freezing it at no higher than 45°C (25°C) Thaw to obtain a cellulose solution;

[0050] 2) Using the cellulose solution obtained in step 1 as the continuous phase, paraffin wax (10 parts) and calcium stearate (2 parts) with a melting point of 28 ° C, diphenylmethane diisocyanate (0.6 parts), toluene diisocyanate (1.5 parts) part) as dispersed phase, and form emulsion; High-speed shearing machine 12000r / min forms emulsion;

[0051] 3) Induce the prepolymer of the above system to form a polymer at the oil-water interface of the emulsion droplet; use 0.02 parts of ethylenediamine as the initiator, and allow the system to mix uniformly for 1 minute...

Embodiment 2

[0059] A regenerated cellulose filament with improved protein effective content is prepared by the following method:

[0060] 1) By dissolving cellulose with a degree of polymerization of 550 in sodium hydroxide containing 9% (7%-10%) by mass, 0.25% (0.1%-5%) of zinc oxide in water and ionic liquid 1-formazan Base-3 butylimidazolium chloride) (wherein, the amount of water is 20%, and the ionic liquid is the balance), frozen to below -7°C, and then thawed at 40°C to obtain a cellulose solution;

[0061] 2) Use the cellulose solution obtained in step 1 as the continuous phase, and use cellulose mass ratio of 35% silk protein and 2% dispersant Span80 and PEG-grafted cellulose with a molecular weight of about 1300 (the ratio is 1: 3) as the dispersion Phase, drop the continuous phase into the dispersed phase with the phase inversion method at a rate of 0.5ml / min and form an emulsion;

[0062] 3) After the emulsion is formed, toluene diisocyanate with a cellulose mass ratio of 8.5...

Embodiment 3

[0070] A regenerated cellulose filament that increases the effective content of a thermochromic material is prepared by the following method:

[0071] 1) by bamboo cellulose, be dissolved in the sodium hydroxide that contains mass ratio 7%, in the N-methylmorpholine-N-oxide aqueous solution of 4.5% zinc oxide, be frozen to below-5 ℃, then without Thaw at a temperature higher than 40°C to obtain a cellulose solution;

[0072]2) Using the cellulose solution obtained in step 1 as the continuous phase, three-stage thermochromic pigments with critical temperatures of 50°C and 70°C, 15-25% phase-change paraffin wax and 5% cellulose mass ratio of 10-25% The dispersant styrene-maleic anhydride resin is used as the dispersed phase and forms an emulsion;

[0073] 3) During the formation of the emulsion, dropwise add 2% nano-kaolin particles and 10% melamine resin aqueous solution with cellulose mass ratio;

[0074] 4) Induce the above-mentioned system prepolymer to form a polymer at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com