Device for microwave-assisted double bed layer catalysis of fast pyrolysis of biomass

A pyrolysis and microwave technology, which is applied in the preparation of liquid hydrocarbon mixtures, the petroleum industry, and the treatment of hydrocarbon oil, etc., can solve the problems of low catalyst utilization efficiency, low bio-oil yield, slow heating rate, etc., to reduce secondary heat hydrolysis reaction, improving the quality of bio-oil, increasing the yield and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

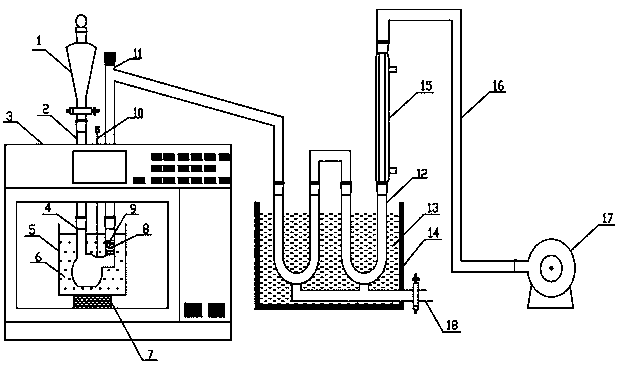

[0018] A microwave-assisted dual-bed catalytic rapid pyrolysis device for biomass, consisting of a feeder 1, a feed port 2, a microwave pyrolysis instrument 3, a double-ported quartz reaction bottle 4, a quartz cup 5, and a microwave absorbent bed 6 , heat insulation block 7, catalyst bed 8, quartz wool 9, K-type thermocouple 10, gas outlet 11, U-shaped condenser pipe 12, condensed water 13, glass container 14, condenser pipe 15, air guide pipe 16, air pump 17 , The biological oil collection port 18 is formed.

[0019] The feeder 1 is connected to the feed port 2, and the bottom of the feed port 2 is connected to the inlet of the double-port quartz reaction bottle 4, and the double-port quartz reaction bottle 4 is placed in the quartz cup 5 filled with the microwave absorber bed 6, and the quartz cup 5 is placed In the microwave pyrolysis instrument 3, an insulating block 7 is placed at the bottom of the quartz cup 5, a catalyst bed 8 and quartz wool 9 are placed at the outlet...

Embodiment 2

[0022] like figure 1 As shown, add 6kg silicon carbide into the quartz cup, 50g HZSM-5 molecular sieve catalyst (diameter 5mm, Si / Al=50, specific surface area 640m 2 / g) placed on the catalyst bed, embed the two-necked quartz bottle in a quartz cup equipped with a microwave absorber, place it in a microwave pyrolysis instrument, turn on the air pump so that the vacuum degree of the reaction system is 100 mm Hg, and fix the power Raise the temperature to 550°C, turn on the feeder switch and quickly add 100g of bamboo chips to the quartz reaction bottle, continue to maintain the catalytic pyrolysis at 550°C until the reaction is complete, and collect the bio-oil product from the bio-oil collection port.

Embodiment 3

[0024] like figure 1 As shown, add 6kg silicon carbide into the quartz cup, 50g HZSM-5 molecular sieve catalyst (diameter 5mm, Si / Al=50, specific surface area 640m 2 / g) placed on the catalyst bed, embed the two-necked quartz bottle in a quartz cup equipped with a microwave absorber, place it in a microwave pyrolysis instrument, turn on the air pump so that the vacuum degree of the reaction system is 100 mm Hg, and fix the power Raise the temperature to 550°C, turn on the feeder switch and quickly add 100g of rice straw to the quartz reaction bottle, continue to maintain the catalytic pyrolysis at 550°C until the reaction is complete, and collect the bio-oil product from the bio-oil collection port.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com