Fluorophlogite/fluoroapatite glass ceramics and preparation method thereof

A technology of fluorophlogopite and fluoroapatite, which is applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve the problem of high energy consumption, achieve the effects of simplifying the production process, reducing production costs, and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The preparation method of the fluorphlogopite / fluoroapatite glass-ceramic of the present embodiment comprises the following steps:

[0034] 1) Put the fluorophlogopite powder and fluoroapatite powder in the corundum ball milling tank respectively, so that the mass ratio of the two is 9:1, add alcohol and zirconia balls, and carry out wet ball milling and grinding at 300r / min. Mixing: After ball milling for 2 hours, pour the material into a beaker and dry it at 60°C. After the material is fully dried, ball mill it at a speed of 200r / min for 1.5 hours to make the mixture completely powdery and obtain the mixture. Mixed material is crossed 200 mesh sieves again, obtains and gets undersieve;

[0035] 2) Put the undersize material in a graphite mold, apply a pressure of 0.6MPa, and then heat it up to 600°C at a heating rate of 5°C / min. Processing, and surface grinding and polishing, that is.

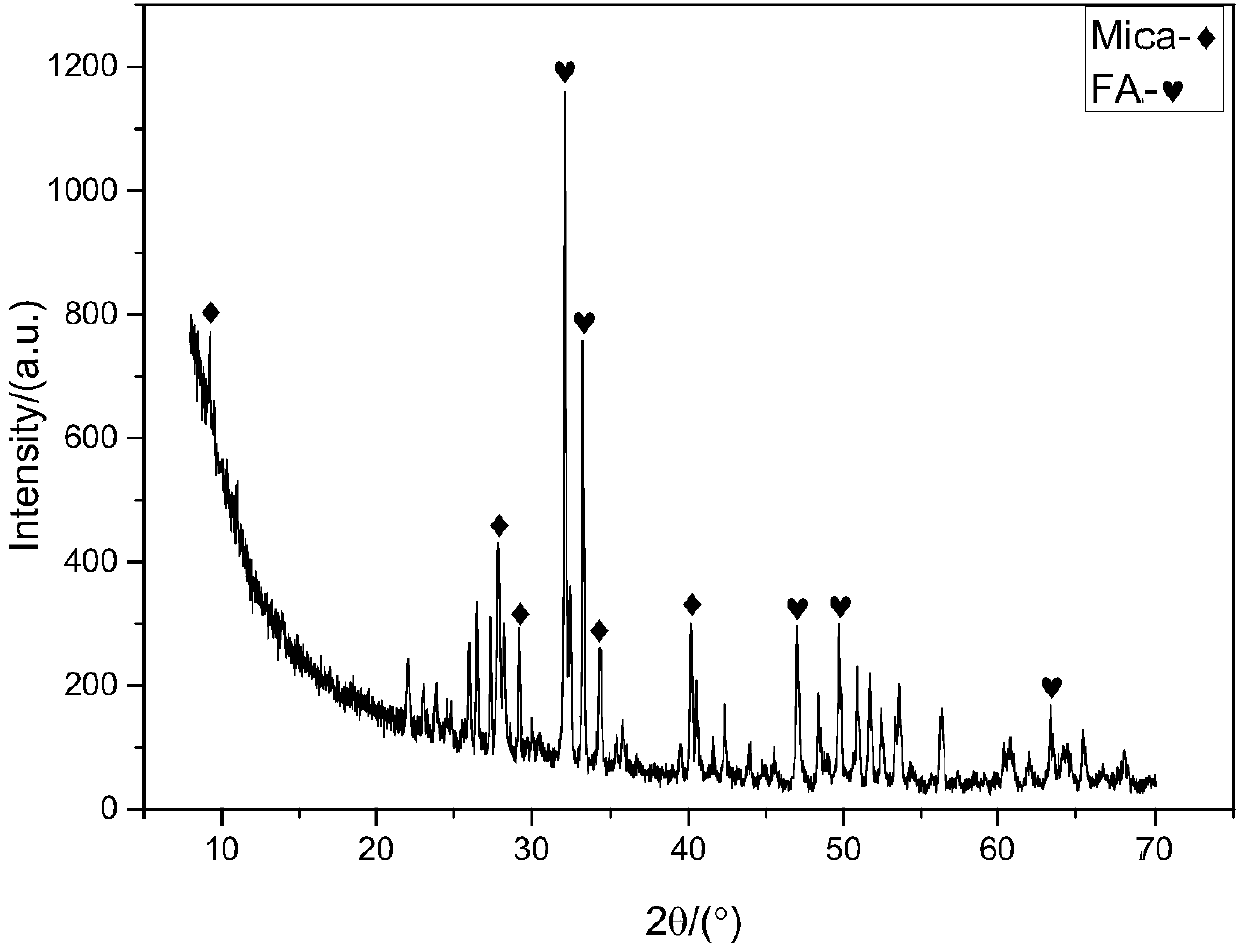

[0036] The fluorphlogopite / fluoroapatite glass-ceramic of this example is prepar...

Embodiment 2

[0038] The preparation method of the fluorphlogopite / fluoroapatite glass-ceramic of the present embodiment comprises the following steps:

[0039] 1) Put the fluorophlogopite powder and fluoroapatite powder in the corundum ball milling tank respectively, so that the mass ratio of the two is 8:2, add alcohol and zirconia balls, and carry out wet ball milling and grinding at 400r / min Mixing: After ball milling for 2 hours, pour the material into a beaker and dry it at 70°C. After the material is fully dried, ball mill it at a speed of 200r / min for 1.5 hours to make the mixture completely powdery and obtain the mixture. Mixed material is crossed 200 mesh sieves again, obtains and gets undersieve;

[0040]2) Put the undersize material in a graphite mold, apply a pressure of 5.0 MPa, and then heat it up to 700°C at a heating rate of 10°C / min. Processing, and surface grinding and polishing, that is.

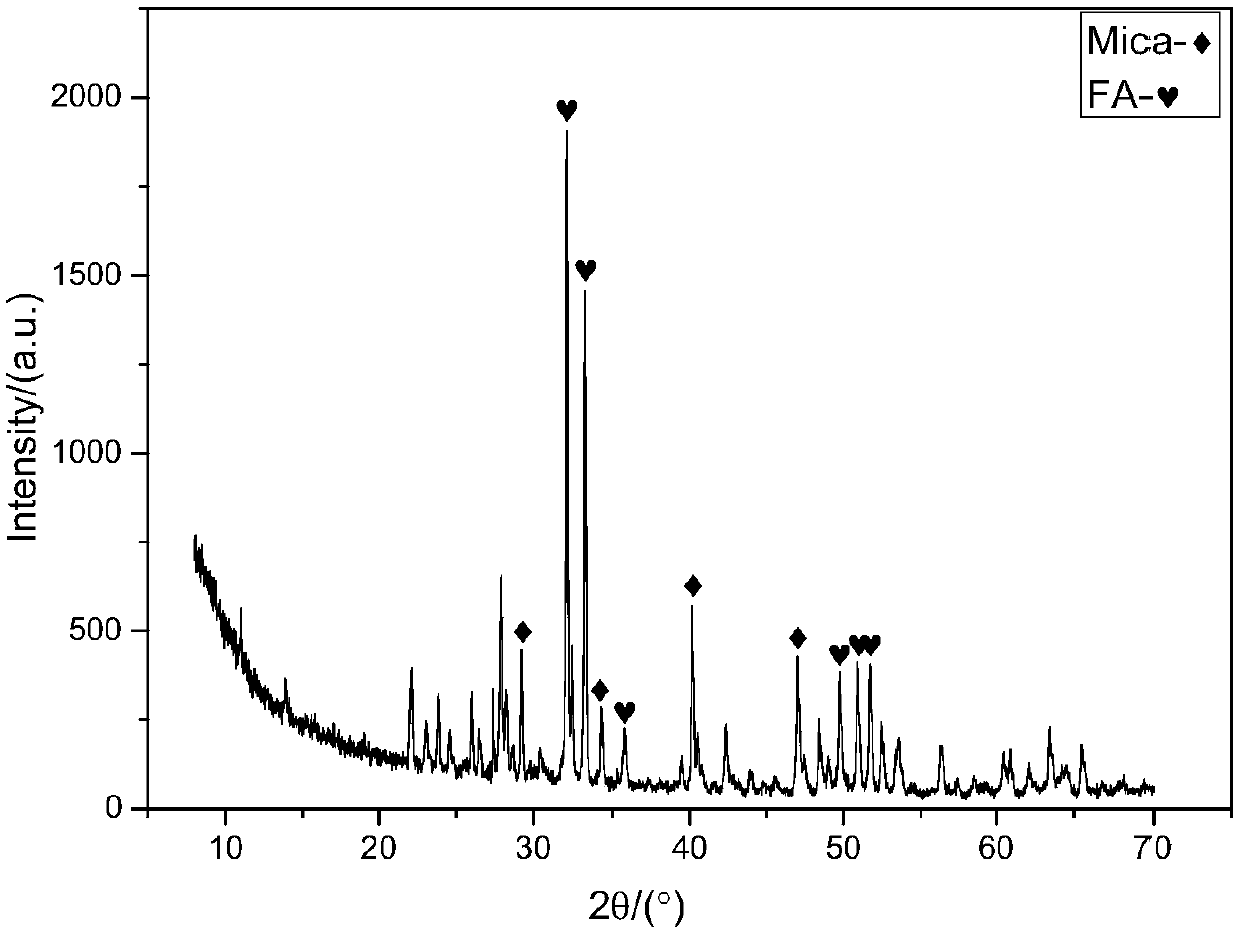

[0041] The fluorphlogopite / fluoroapatite glass-ceramic of this example is prepar...

Embodiment 3

[0044] The preparation method of the fluorphlogopite / fluoroapatite glass-ceramic of the present embodiment comprises the following steps:

[0045] 1) Put the fluorophlogopite powder and fluoroapatite powder in the corundum ball milling tank respectively, so that the mass ratio of the two is 7:3, add alcohol and zirconia balls, and carry out wet ball milling and grinding at 300r / min. Mixing: After ball milling for 1 hour, pour the material into a beaker and dry it at 60°C. After the material is fully dried, ball mill it at a speed of 200r / min for 1.5 hours to make the mixture completely powdery and obtain the mixture. Then the mixture is crossed through a 200-mesh sieve to obtain the under-sieve;

[0046] 2) Put the undersize material in a graphite mold, apply a pressure of 0.6MPa, and then heat it up to 600°C at a heating rate of 5°C / min. Processing, and surface grinding and polishing, that is.

[0047] The fluorphlogopite / fluoroapatite glass-ceramic of this example is prepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com