Glass powder for PERC aluminum paste and preparation method thereof

A technology of glass powder and aluminum paste, applied in the field of back electrode paste of solar cells, can solve the problem that there is a large space for improving efficiency, and achieve the effects of being conducive to bonding, matching thermal expansion coefficient, and high softening point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

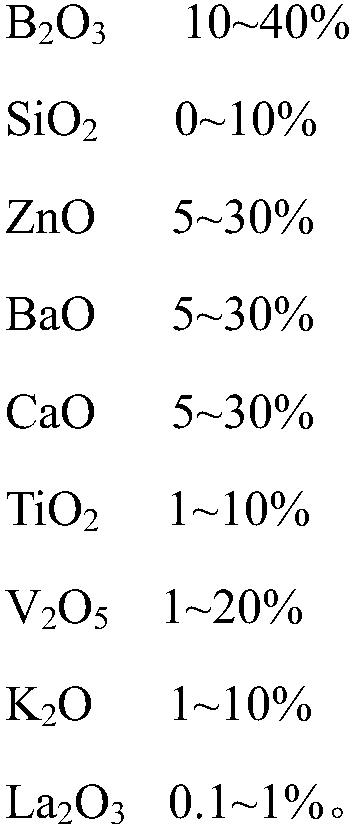

[0032] The glass powder for PERC aluminum paste provided in this embodiment is made of the following raw materials in mass percentage:

[0033]

[0034] The preparation method of the glass powder for PERC aluminum paste comprises the following steps: selecting raw materials, mixing them evenly, and melting them in a muffle furnace to obtain a refining liquid, drying and crushing the refining liquid after water quenching, and then ball milling and drying. Prepare glass frit for PERC aluminum paste.

[0035] Among them, a V-type mixer is used for dry mixing during mixing, the temperature during smelting is 900°C-1200°C, and the holding time is 30-90min.

[0036] Deionized water is used for water quenching, deionized water is used as the medium for ball milling, and the ball milling time is 20-48 hours. After the ball-milled glass slurry is left to stand, the upper layer of water is separated and removed, and then dried in an oven at 110-130°C.

Embodiment 2

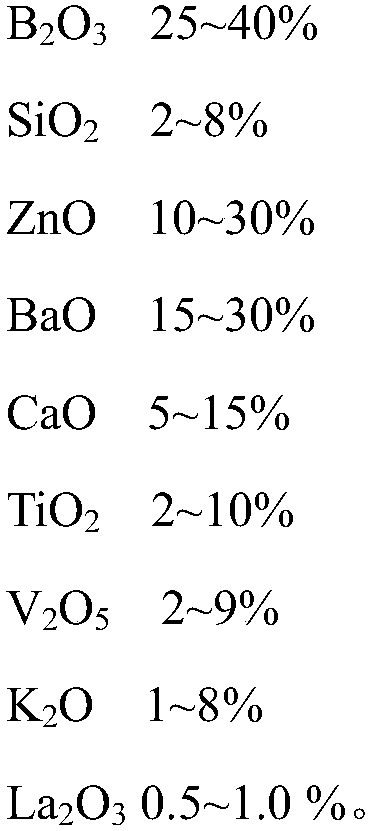

[0038] The glass powder for PERC aluminum paste provided in this embodiment is made of the following raw materials in mass percentage:

[0039]

[0040] For the preparation method of the glass powder for PERC aluminum paste, refer to Example 1.

Embodiment 3

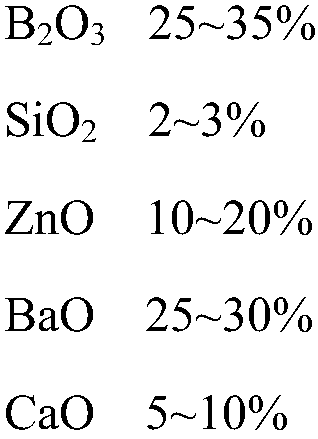

[0042] The glass powder for PERC aluminum paste provided in this embodiment is made of the following raw materials in mass percentage:

[0043]

[0044] For the preparation method of the glass powder for PERC aluminum paste, refer to Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com