Cooking method for pressure cooker

A cooking method and pressure cooker technology, which is applied in pressure cookers, cooking utensils, heating devices, etc., can solve the problems of unsatisfactory food, inconvenience for users, and prolonged cooking time, so as to achieve direct taste effect and speed up the pressure reduction speed , The effect of promoting the drop of the float

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The invention provides a cooking method in a pressure cooker.

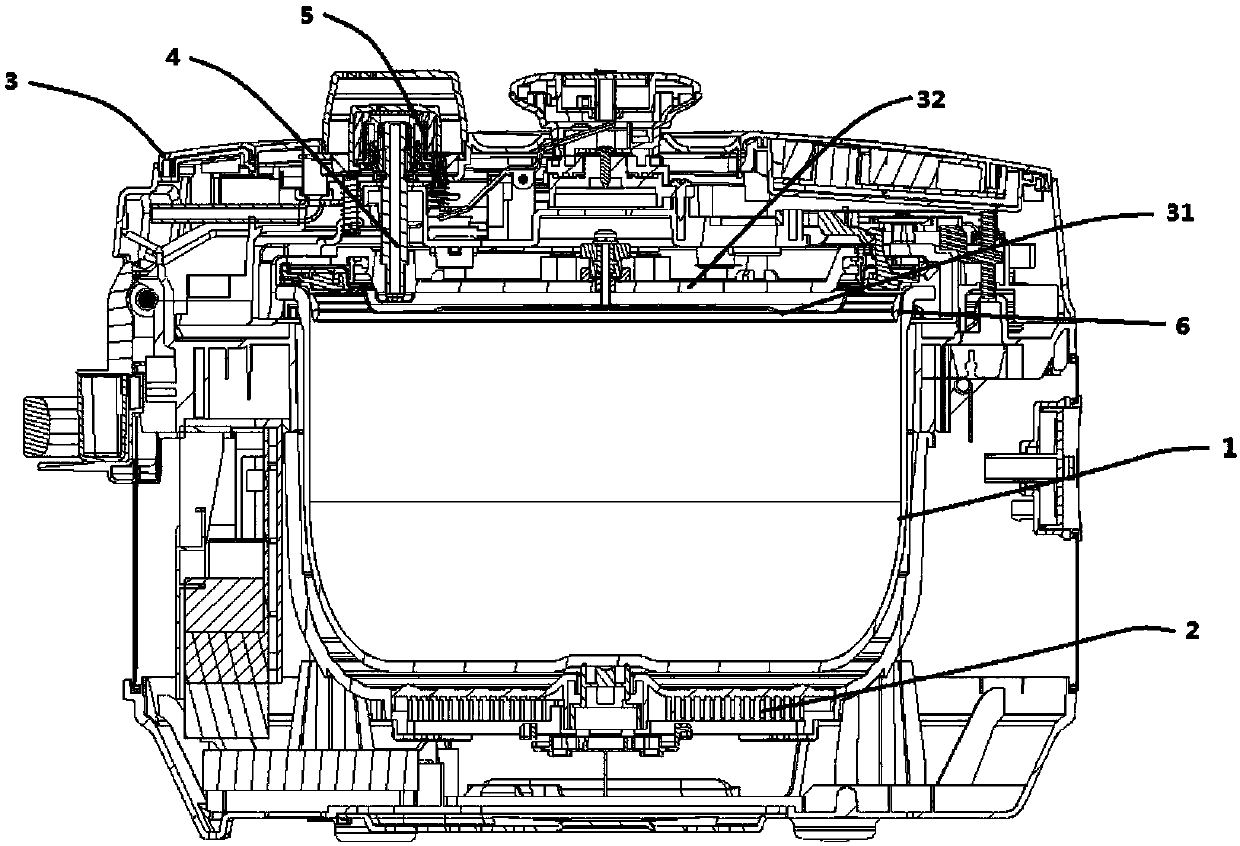

[0032] Such as figure 1 As shown, the pressure cooker of this embodiment includes an inner container 1, a heating element 2 for heating the inner container 1, a control element for controlling the heating element 2, and a pot cover 3 that is sealed with the inner container 1 to form a cooking cavity. The float on the cover 3 and the exhaust pipe 4, the pressure relief valve 5 arranged on the exhaust pipe 4, the cooling device for cooling the cooking cavity. The heating element 2 can be an electromagnetic wire disk or a heating disk or other heating methods, and the heating element can be arranged at the bottom, side wall, or top of the inner container. It can be understood that the pressure cooker also includes a detection device for detecting the cooking cavity, and the detection device feeds back a detection signal to the control element. The detection device is a temperature detection device or a press...

Embodiment 2

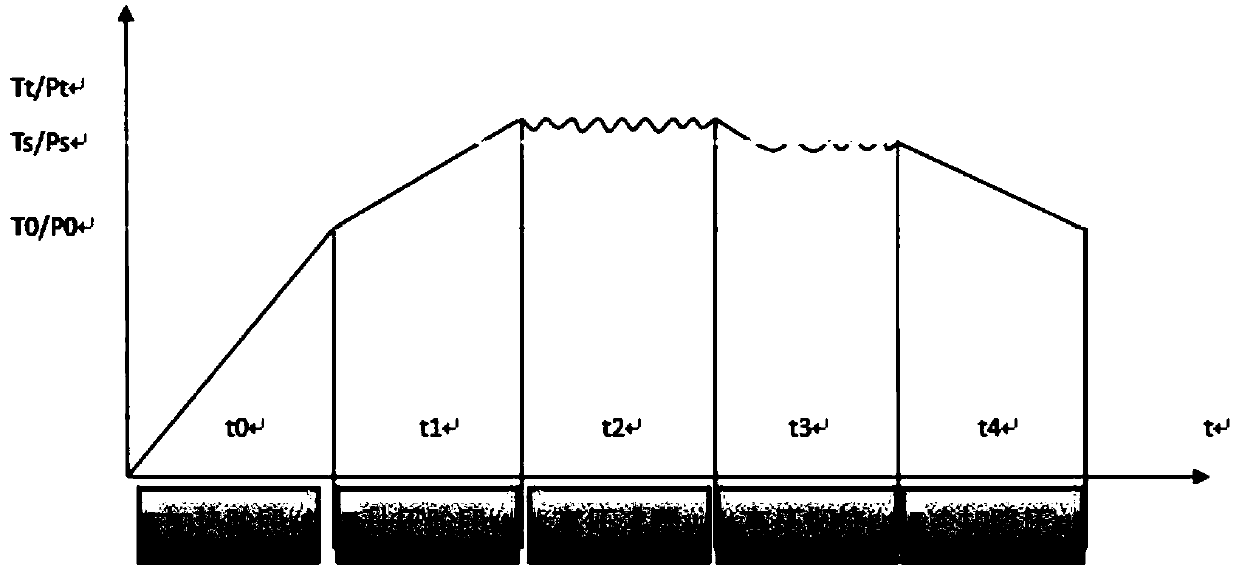

[0048] This embodiment is a further improvement on the basis of the first embodiment. Specifically, the detection device in this embodiment is a temperature detection device, and the detection device includes a top temperature detection device and a bottom temperature detection device. The top temperature detection device is set on the top of the cooking cavity, specifically, it is set on the inner cover, which can detect the steam generated by the cooking cavity through the inner cover, or stick on the inner cover to monitor the temperature of the inner cover. detection, or fit the upper side wall of the inner tank to detect the upper part of the inner tank. The bottom temperature detection device is installed at the bottom of the inner tank. When the inner tank is placed on the pot body, the bottom temperature detection device is attached to the bottom of the inner tank. Since the top temperature detection device is arranged at the top of the cooking cavity, the heating ele...

Embodiment 3

[0053] In this embodiment, the pressure cooker is improved on the basis of Embodiment 1 or Embodiment 2, or in other words, the pressure cooker of this embodiment is used and the cooking method of Embodiment 1 or Embodiment 2 is used, which has a better effect.

[0054] Specifically, refer to figure 1 , the pot cover 3 of the pressure cooker of the present embodiment includes an upper inner cover 31 and a lower inner cover 32, the upper inner cover 31 is provided with a float and an exhaust pipe 4, and the lower inner cover 32 is A sealing ring 6 is provided to cooperate with and seal the inner container 1, and the lower inner cover 32 is also provided with vent holes.

[0055] After the liner of this embodiment is heated, the steam generated can enter the passage of the float and the exhaust pipe 4 through the vent hole of the lower inner cover 32, so as to ensure the normal use of the float and the exhaust pipe 4. Preferably, the position of the air hole is staggered from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com