A heating strip and a hot runner and a cold runner structure using the heating strip

A technology of heating strips and hot runners, which is applied in the field of hot runners and cold runners of injection molds, and can solve problems such as the inability to ensure uniform heating of the heating strips, the inability to produce glue, and the inability to ensure the temperature difference between the template 6 of the cold runner.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

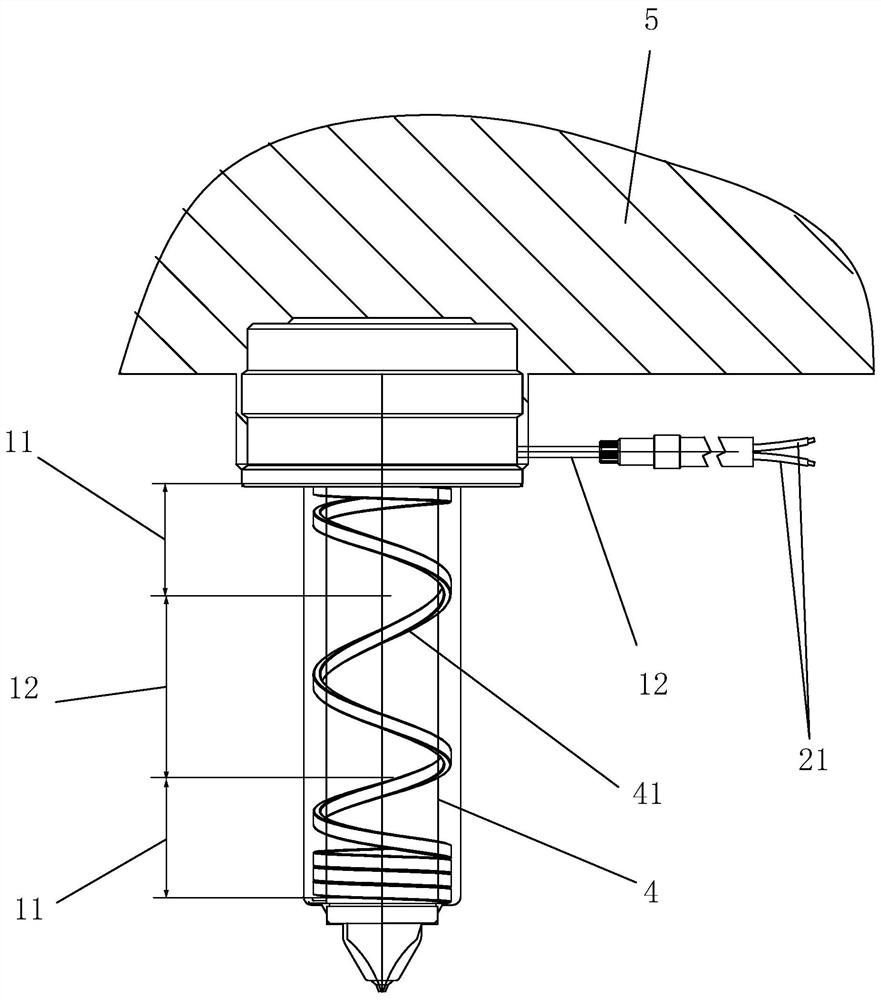

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

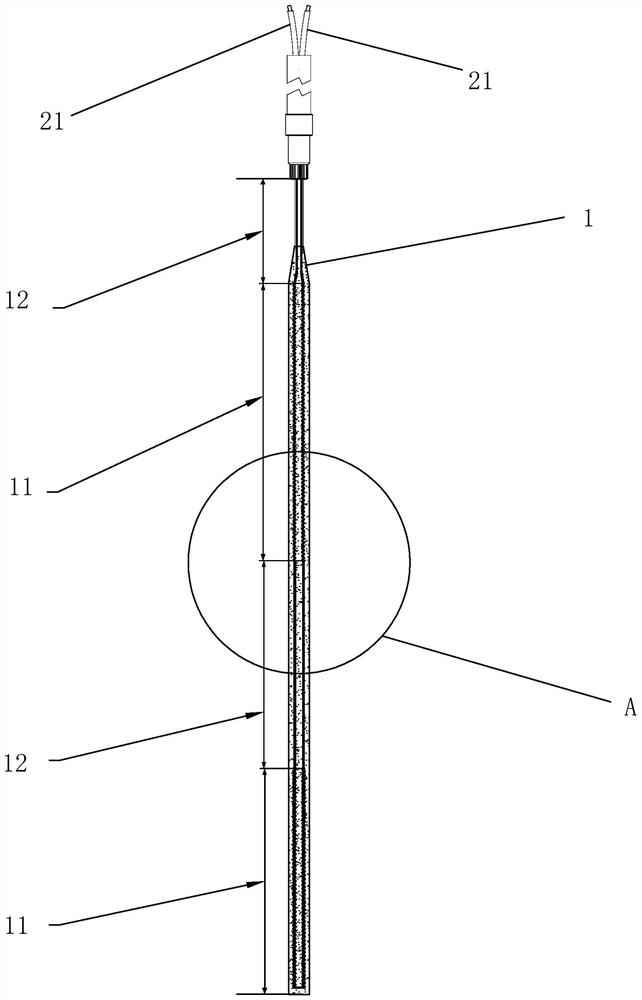

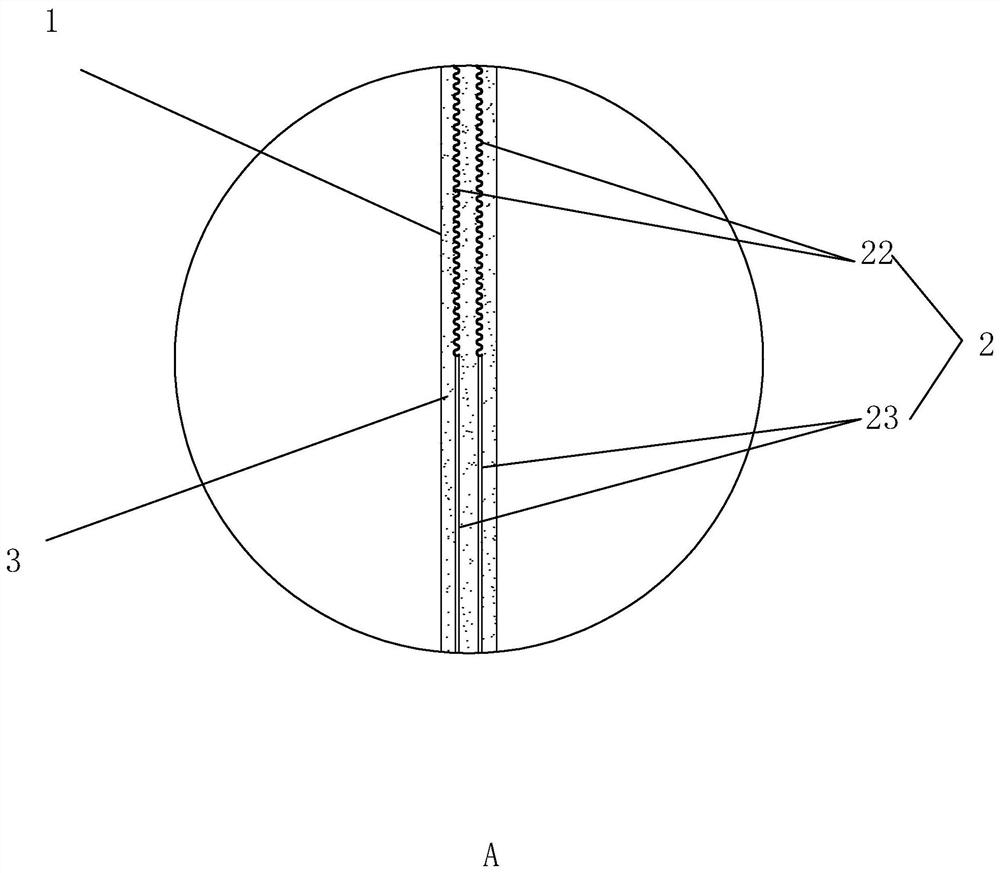

[0024] A heating strip, cf. figure 1 with 2 , which includes a metal capillary 1 and a heating wire 2 located between the metal capillary 1, the metal capillary 1 is made of pure nickel material; the metal capillary 1 is filled with magnesium oxide powder 3, which has the effect of insulating heat conduction; the heating wire 2 is located in the metal capillary Electrodes 21 are provided at both ends of 1 for connecting to the temperature control box, and the heating wire 2 is folded in half inside the metal capillary 1 to form a loop.

[0025] The heating wire 2 includes successively adjacent heating wires 22 and low thermal conductivity wires 23. The heating wire 22 is made of CrNi2080 material, which can generate heat when energized, and the low thermal conductivity wire 23 is made of pure nickel material, which has poor thermal conductivity and relative...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com