An x-ray filament power supply device based on laser energy supply technology

A filament power supply and laser energy supply technology, applied in laser technology and its application fields, can solve the problems of inability to meet the power requirements of X-ray filament power supply, limitations, etc., and achieve the effect of solving serious electromagnetic interference, good temperature characteristics, and prolonging life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail, and following embodiment is explanation of the present invention and the present invention is not limited to following example, but can not limit the scope of the present invention.

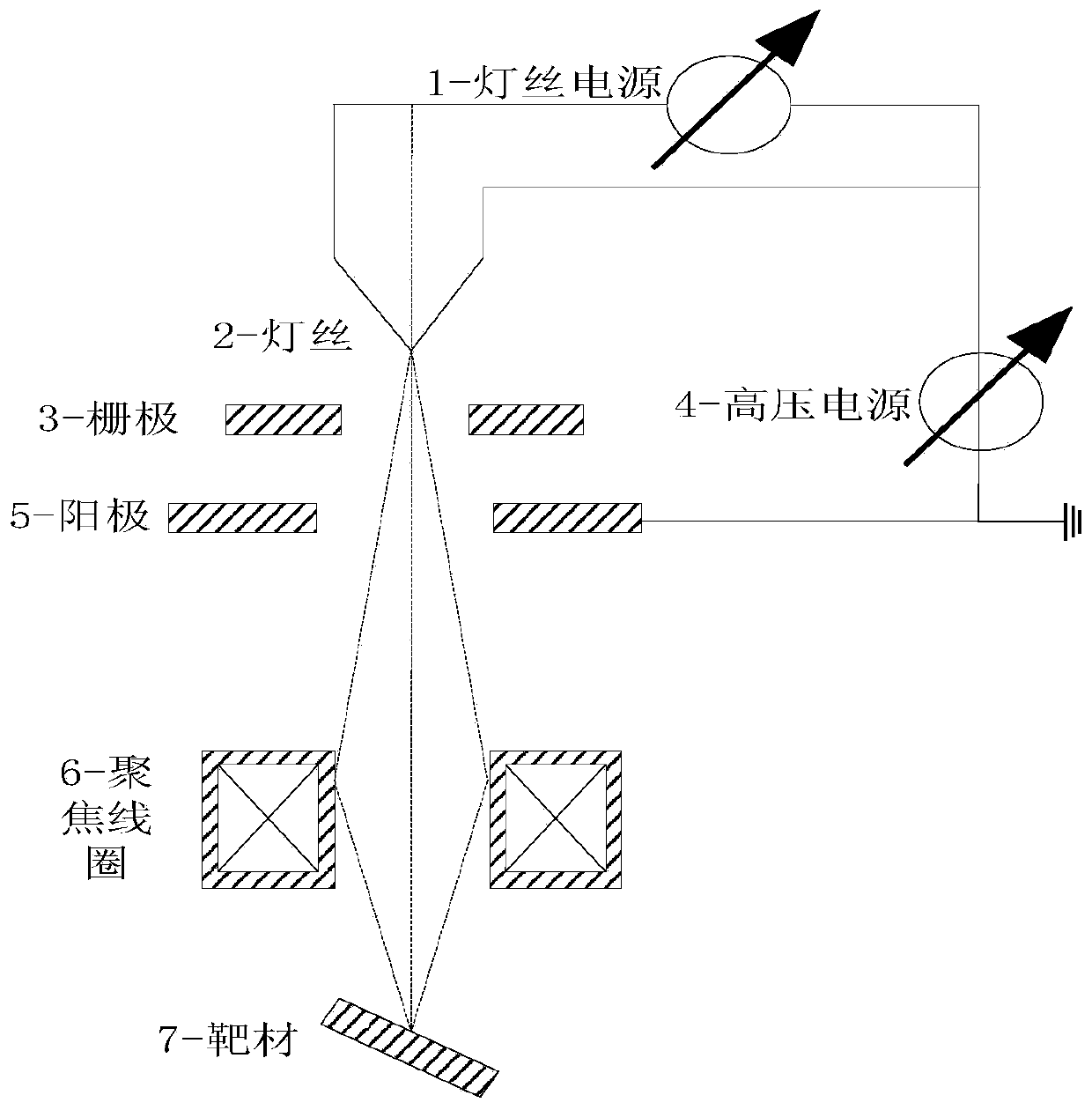

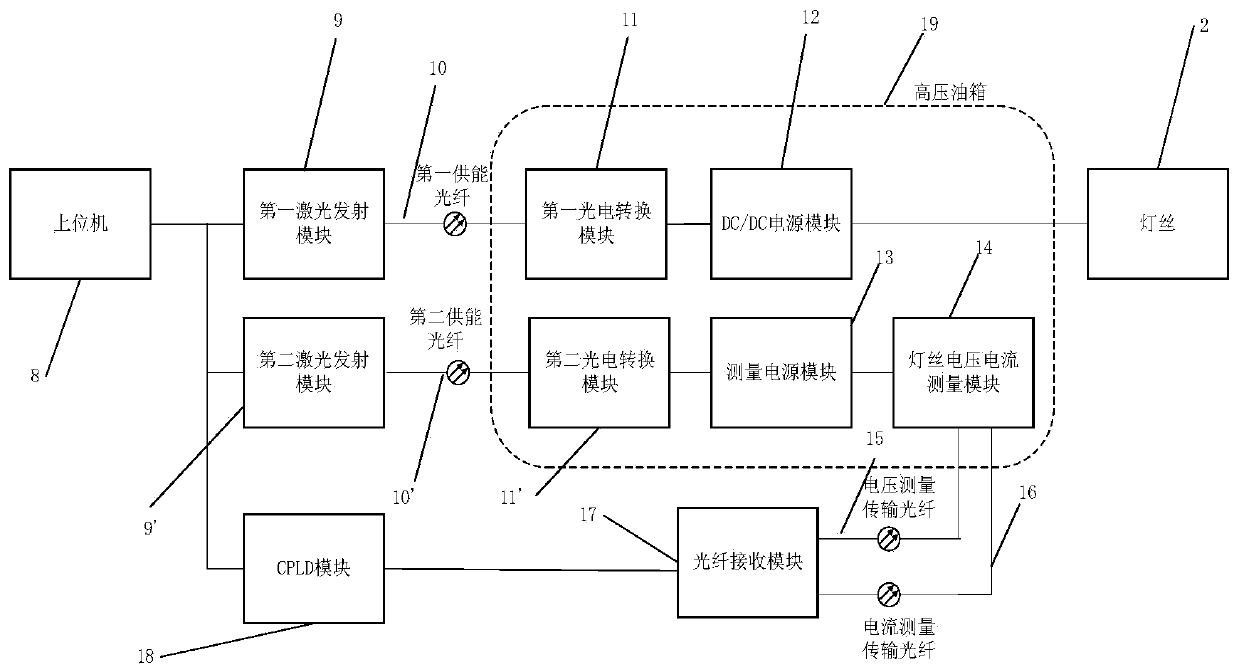

[0027] like figure 1 As shown, in the process of X-ray emission, the target 7 is made of high melting point metal (generally Fe or Cu). The filament power supply 1 heats the filament 2 after being powered on, and the filament can emit thermal electrons. At the same time, the electrons generated are accelerated by a high-voltage power supply 4 of tens of thousands of volts to hundreds of thousands of volts, and the electron beam bombards the target 7, and the electrons lose kinetic energy and radiate in the form of photons. , X-rays are emitted from the target. At the same time, the filament power supply 1 needs to float on the high voltage power supply 4 . The filament powe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com