Simple and green cross-linked composite anion exchange membrane and preparation method thereof

An anion exchange membrane and composite technology, applied in the field of cross-linked composite anion exchange membrane and its preparation, can solve the problem that the membrane is difficult to balance electrical conductivity and mechanical properties, chemical stability and mechanical properties are decreased, and the synthesis method of copolymerized AEMS is complicated. and other problems, to achieve the effect of taking into account the conductivity-stability and the green synthesis method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

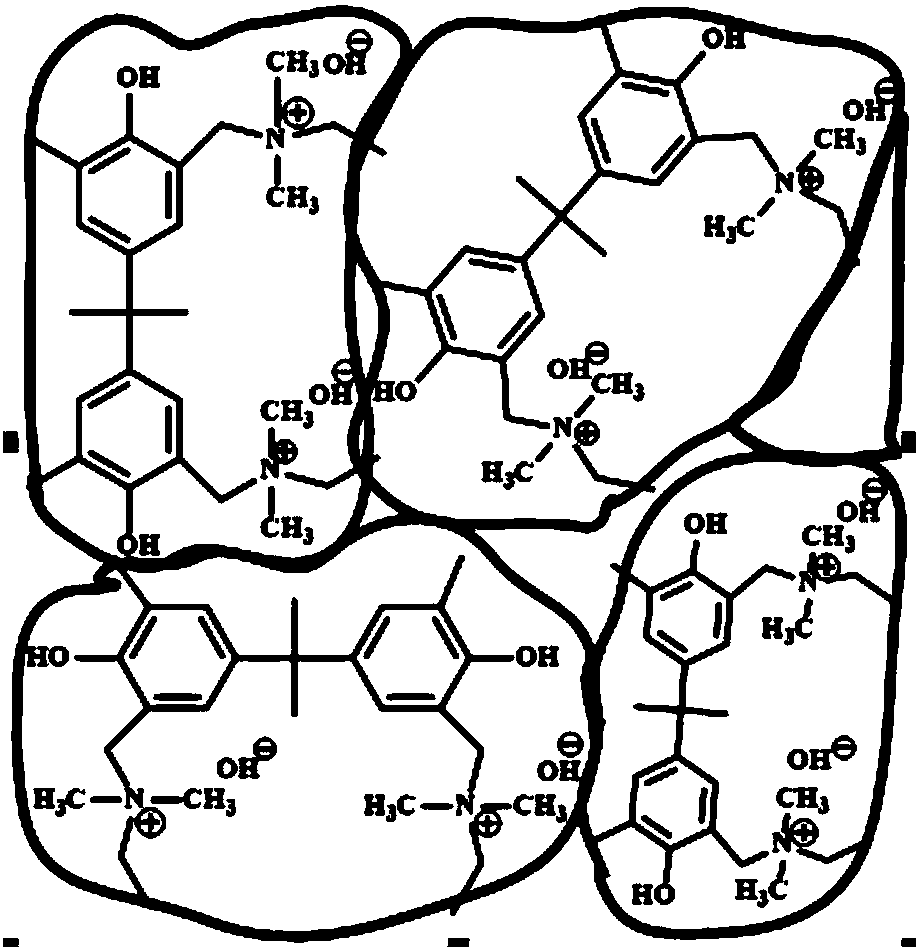

[0025] The first step, synthesis of polybenzoxazine (BZ)

[0026] At 8°C, add 16ml of methylamine and 18ml of dioxane dropwise into a mixed solution of 28ml of formaldehyde and 75ml of dioxane to dissolve, stir well, then add 95ml of 0.1mol / l bisphenol A solution, The reaction at 40° C. was completed after 6 hours. The reacted solution was washed with 40 ml of ethyl acetate and 40 ml of deionized water, then dried with anhydrous magnesium sulfate, and the ethyl acetate was evaporated in vacuum to obtain a benzoxazine monomer solution. Phenolics in the resulting solution were removed by washing with 3M NaOH.

[0027] In the second step, ethanol swells the microporous basement membrane

[0028] The microporous membrane was immersed in ethanol solution for 2 hours at room temperature to obtain a swollen microporous membrane. The microporous base membrane is a polysulfone microporous membrane. The pore diameter is 0.4 microns, the porosity is 70%, and the thickness is 16 micron...

Embodiment example 2

[0033] The first step, synthesis of polybenzoxazine (BZ)

[0034] At 10°C, add 17ml of methylamine and 20ml of dioxane dropwise into a mixed solution of 30ml of formaldehyde and 80ml of dioxane to dissolve, stir well, then add 98ml of 0.1mol / l bisphenol A solution, After reacting at 50°C for 8 hours, the reaction was completed. The reacted solution was washed with 60 ml of ethyl acetate and 60 ml of deionized water, then dried with anhydrous magnesium sulfate, and the ethyl acetate was evaporated in vacuum to obtain a benzoxazine monomer solution. Phenolics in the resulting solution were removed by washing with 3M NaOH.

[0035] In the second step, ethanol swells the microporous basement membrane

[0036] The microporous membrane was immersed in ethanol solution with a mass fraction of 99% for 3 hours at room temperature to obtain a swollen microporous membrane. The microporous base film is polyvinylidene fluoride microporous film. The pore size is 0.45 microns, the porosi...

Embodiment example 3

[0041] The first step, synthesis of polybenzoxazine (BZ)

[0042] At 12°C, add 18ml of methylamine and 22ml of dioxane dropwise into a mixed solution of 32ml of formaldehyde and 85ml of dioxane to dissolve. After stirring evenly, add 100ml of 0.1mol / l bisphenol A solution, After reacting at 60°C for 9 hours, the reaction was completed. The obtained solution was washed with 50 ml of ethyl acetate and 50 ml of deionized water, dried over anhydrous magnesium sulfate, and the ethyl acetate was evaporated in vacuum to obtain a benzoxazine monomer solution. Phenolics in the resulting solution were removed by washing with 3M NaOH.

[0043]In the second step, ethanol swells the microporous basement membrane

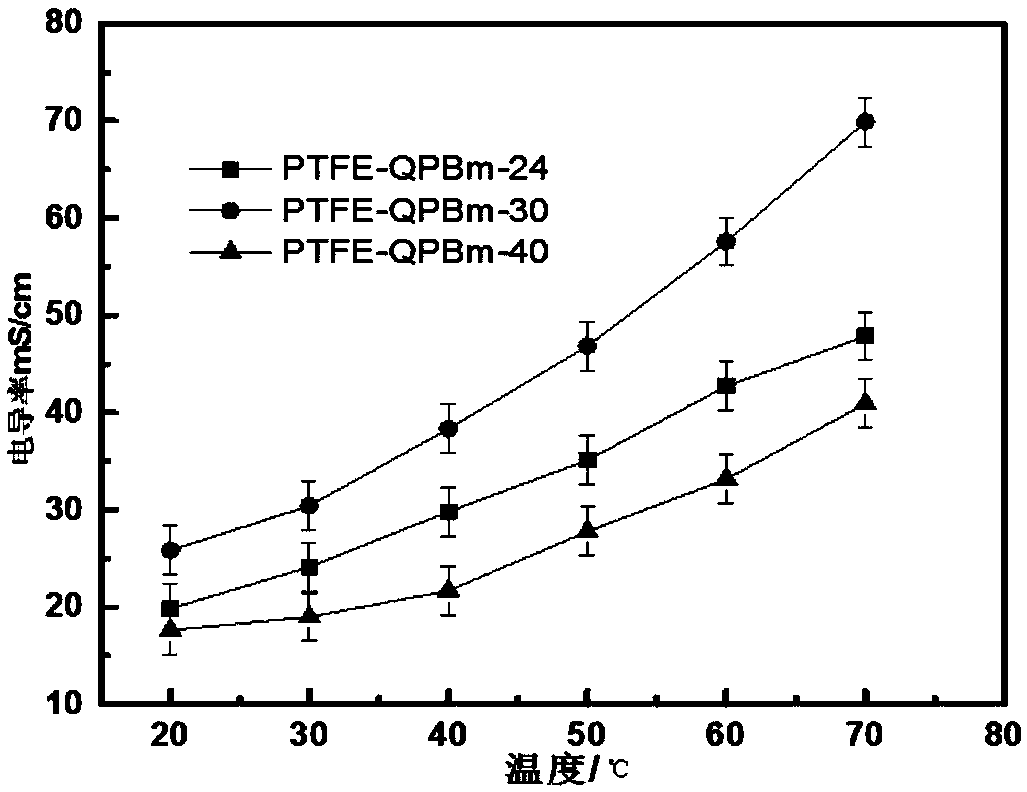

[0044] The microporous membrane was immersed in ethanol solution for 4 hours at room temperature to obtain a swollen microporous membrane. The microporous base membrane is polytetrafluoroethylene microporous membrane. The pore diameter is 0.5 microns, the porosity is 90%, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com