Sheep-based grease microcapsule powder and preparation method thereof

A technology of microcapsules and oils, which is applied in the fields of edible oil/fat, food science, application, etc. It can solve the problems of not achieving the expected effect and the stability effect is too far away, so as to achieve low surface oil and best embedding effect , the effect of increased stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

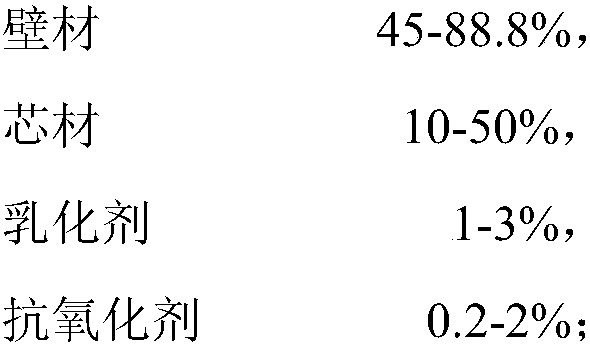

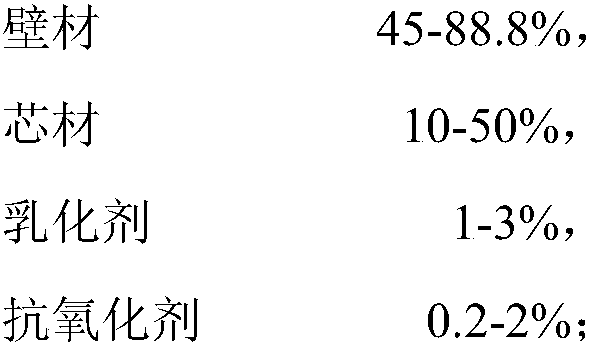

Method used

Image

Examples

Embodiment 1

[0036] (1) Water phase preparation: Weigh 9 kg of sheep casein and 36 kg of sheep lactose, water phase emulsifier mono-, diglyceride fatty acid ester 1 kg, water phase antioxidant sodium ascorbate 1 kg, dissolve in 60 ° C, 100 kg of pure water Medium, keep warm for 30 minutes.

[0037] (2) Preparation of oil phase: Weigh 50 kg of core DHA oil, 2 kg of oil phase emulsifier phospholipid, and 1 kg of oil phase antioxidant ascorbyl palmitate, mix well, then heat up to 60°C and keep warm for 15 minutes.

[0038] (3) Add the oil phase prepared in step 2 into the water phase prepared in step 1, and shear while adding to disperse the oil phase in the water phase to form an emulsion, and simultaneously lower the temperature to 50°C.

[0039] (4) Homogenize the cooled material twice with a homogenizer, the homogenization pressure is 5MPa for the second stage and 45MPa for the first stage.

[0040] (5) Spray-dry the homogenized material at an inlet air temperature of 170° C. and an outl...

Embodiment 2

[0043] (1) Water phase preparation: Weigh 17.76 kg of wall material sheep desalted whey powder, 71.04 kg of glucose, 0.5 kg of water phase emulsifier citric acid fatty acid glyceride, and 0.1 kg of water phase antioxidant sodium ascorbate, dissolve them in 80 °C, 200 kg pure water, keep warm for 60 minutes.

[0044] (2) Oil phase preparation: Weigh 10 kg of core material ARA oil, 0.5 kg of oil phase emulsifier phospholipid, and 0.1 kg of oil phase antioxidant vitamin E, mix well, then heat up to 80°C, and keep warm for 45 minutes.

[0045] (3) Add the oil phase prepared in step 2 into the water phase prepared in step 1, and shear while adding to disperse the oil phase in the water phase to form an emulsion, and simultaneously lower the temperature to 65°C.

[0046](4) Homogenize the material after cooling for 3 times with a homogenizer, the homogenization pressure is 3MPa for the second stage and 30MPa for the first stage.

[0047] (5) Spray-dry the homogenized material at an...

Embodiment 3

[0050] (1) Preparation of water phase: Weigh 14kg of wall material sheep concentrated whey protein powder and 56kg of maltose, water phase emulsifier mono-, diglyceride fatty acid ester 0.5kg and citric acid fatty acid glyceride 0.5kg, water phase antioxidant sodium ascorbate 0.5kg, dissolve in 180kg, 70℃ pure water, keep warm for 40 minutes.

[0051] (2) Preparation of oil phase: Weigh 27kg of core material OPO structural lipid, 1kg of oil phase emulsifier phospholipid, 0.5kg of oil phase antioxidant ascorbyl palmitate, mix well, then heat up to 70°C and keep warm for 30 minutes.

[0052] (3) Add the oil phase prepared in step 2 into the water phase prepared in step 1, and shear while adding to disperse the oil phase in the water phase to form an emulsion, and simultaneously lower the temperature to 60°C.

[0053] (4) Homogenize the material after cooling for 3 times with a homogenizer, the homogenization pressure is 4MPa for the second stage and 40MPa for the first stage.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com