Method for preparing shape memory cyanate ester prepreg

A cyanate ester and prepreg technology, which is applied in the field of preparation of shape memory prepregs for fiber composite materials, can solve the problems of inability to prepare prepregs, poor processability, single structure, etc., and achieve excellent mechanical properties and space resistance Effects of environmental performance, long storage period, and high physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0027] Embodiment 1: This embodiment is a preparation method of shape memory cyanate ester prepreg, which is specifically completed according to the following steps:

[0028] 1. Synthesis of cyanate ester prepolymer: put the cyanate ester monomer in a container, stir at a temperature of 80°C to 250°C until the cyanate ester monomer is completely melted, then add modifier I and polymerization Catalyst, the mass ratio of the modifier I to the cyanate monomer is (0.2~20):100, the mass ratio of the polymerization catalyst to the cyanate monomer is (0.0002~1):100, and in The temperature is 60°C-200°C, stirring and reacting at a constant temperature for 0.25h-10h, and then cooling to room temperature at a cooling rate of 0.5°C / min-5°C / min to obtain a modified cyanate resin prepolymer; the modified Agent Ⅰ is bisphenol A epoxy resin, novolac epoxy resin, p-aminophenol triglycidyl epoxy resin, amino tetrafunctional epoxy resin or bis-horse resin, polyethylene glycol, polyalkylene glyc...

specific Embodiment approach 2

[0039] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the cyanate ester monomer described in step one is bisphenol A cyanate, dicyclopentadiene bisphenol type cyanate, bisphenol F Type cyanate or bisphenol M type cyanate. Others are the same as the first embodiment.

specific Embodiment approach 3

[0040] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: in step one, stir at a temperature of 80°C-250°C and a stirring speed of 500r / min-2500r / min until the cyanate body completely melted. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

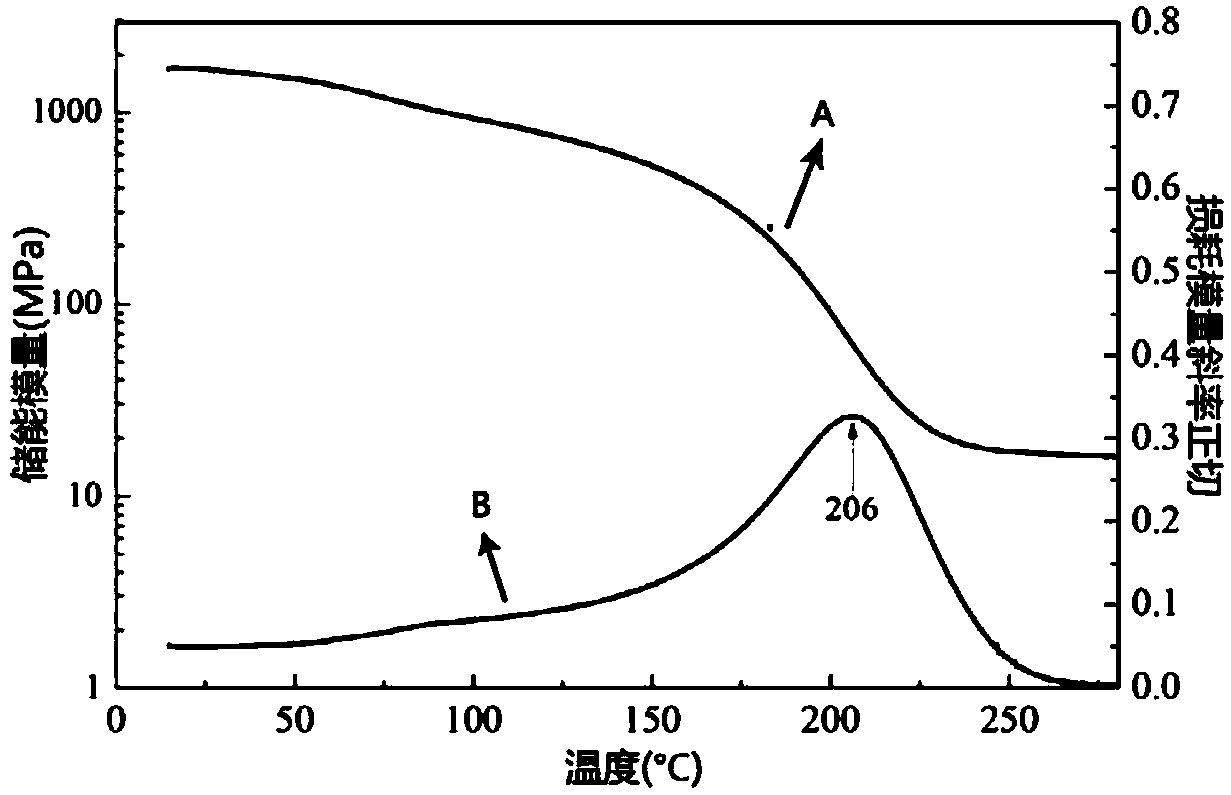

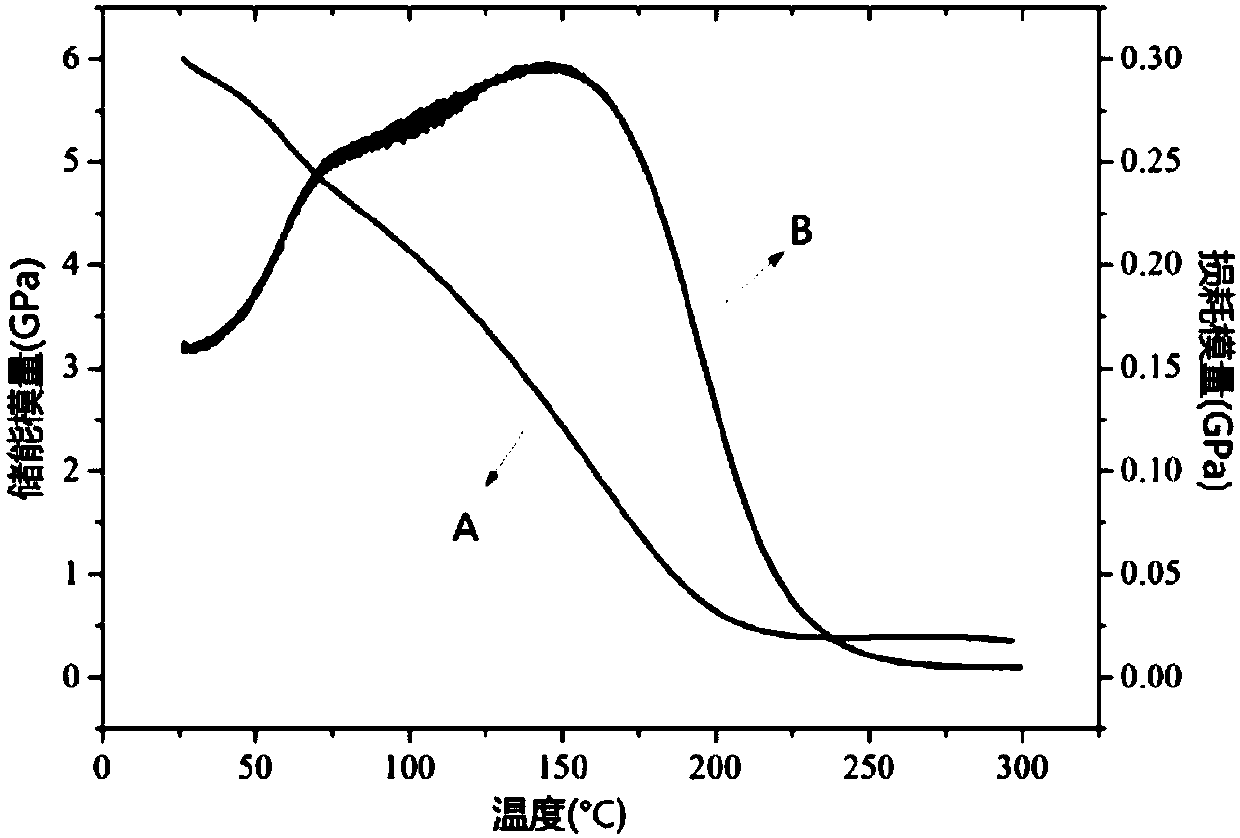

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com