Multi-wheel airplane electric brake electromechanical-driven framework and braking force control method

A technology of brake control and drive control, which is applied in the direction of brakes, vehicle components, brake safety systems, etc., and can solve problems such as grade accidents, inability to compensate braking force, safety accidents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

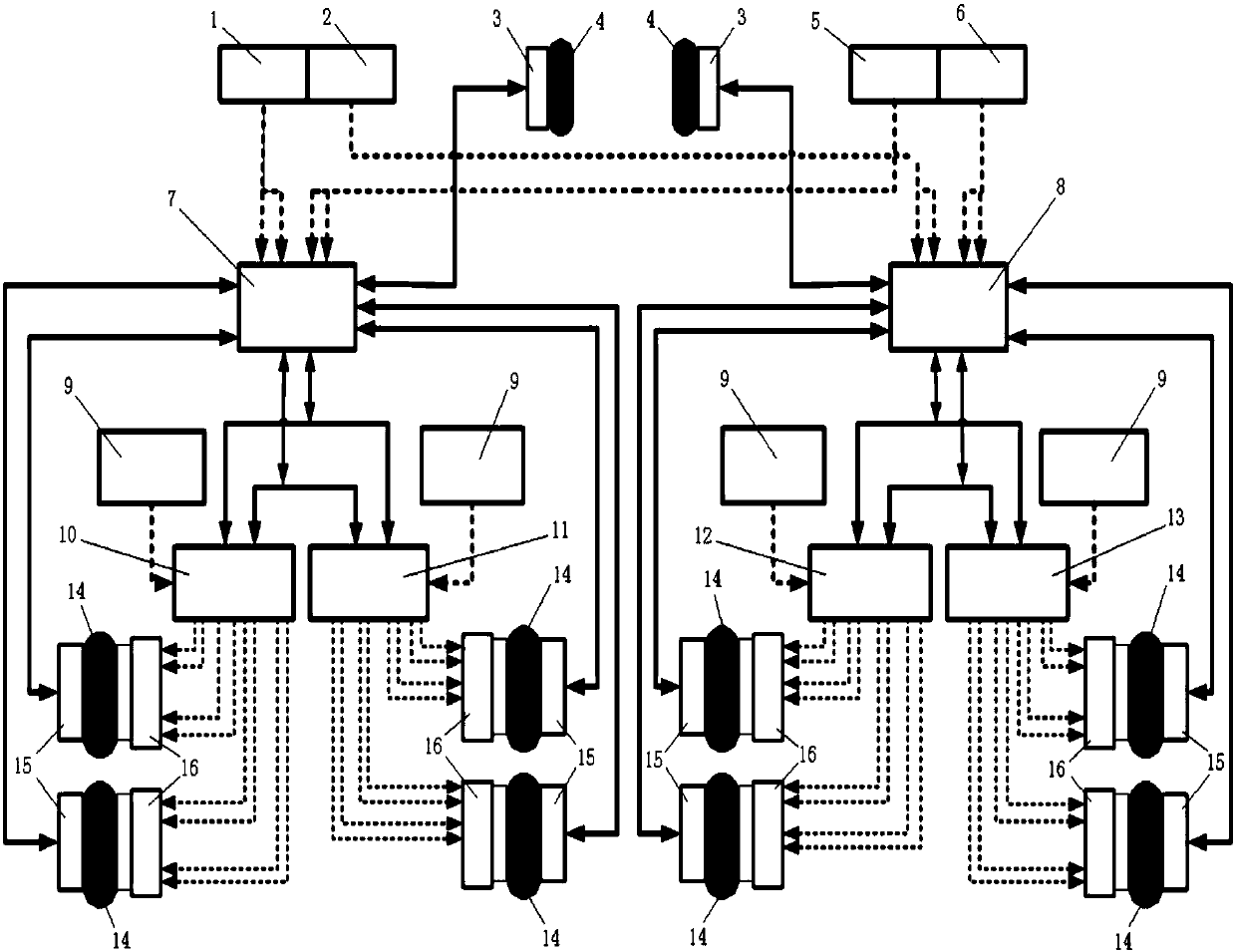

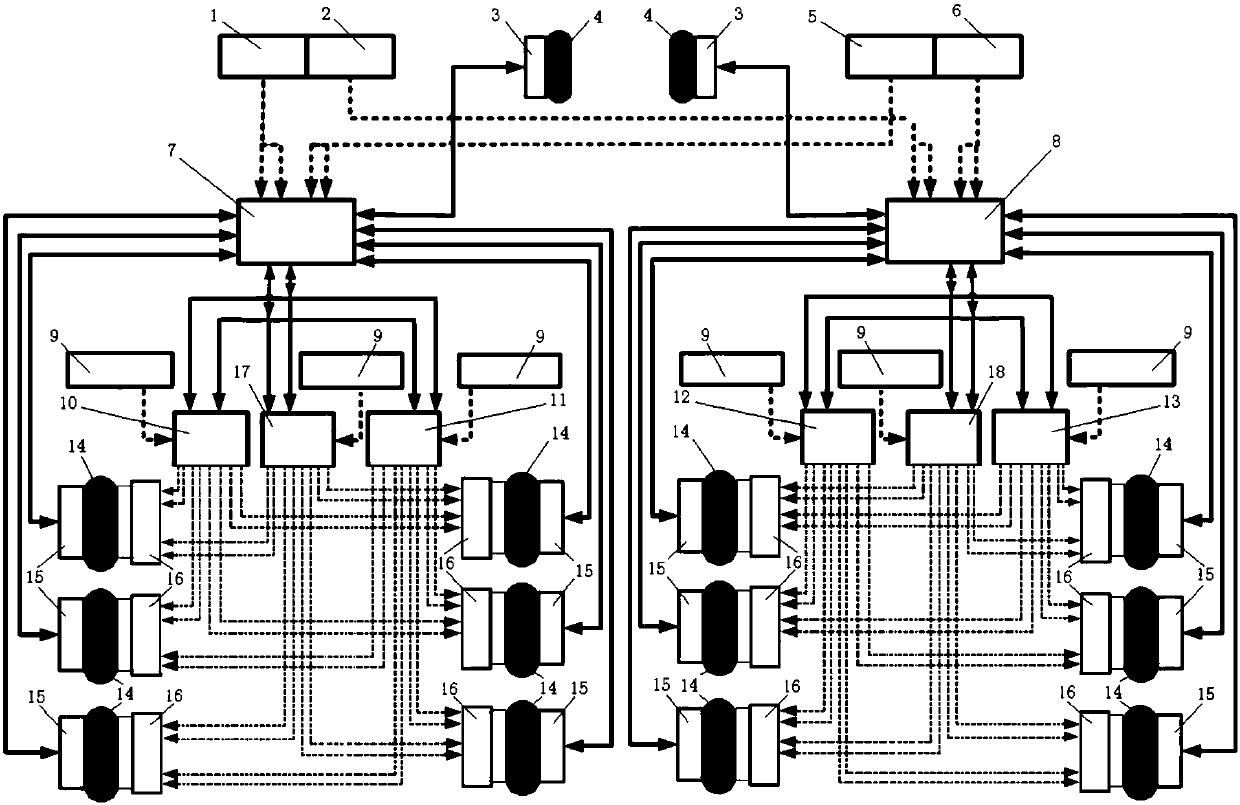

[0053] The present embodiment is a multi-train aircraft electric brake control and monitoring system based on twelve main brake wheels of a certain large aircraft. The left and right sides of described aircraft respectively have the main landing gear of the three struts of front, middle and rear three rows of a group, two wheels are horizontally installed on the axle of each strut, so the main landing gear of every side There are 6 main brake wheels 14, each main brake wheel 14 has a brake device 16 and a main wheel remote data concentrator 15, and four identical electromechanical devices are evenly distributed in the circumferential direction of each brake device end face. Actuator, so that there is a uniform braking pressure between the brake disc and the static disc surface, ensuring the stability of the braking torque and the uniform wear of the disc surface.

[0054] This embodiment includes a command control framework and a drive control framework.

[0055] The command ...

Embodiment 2

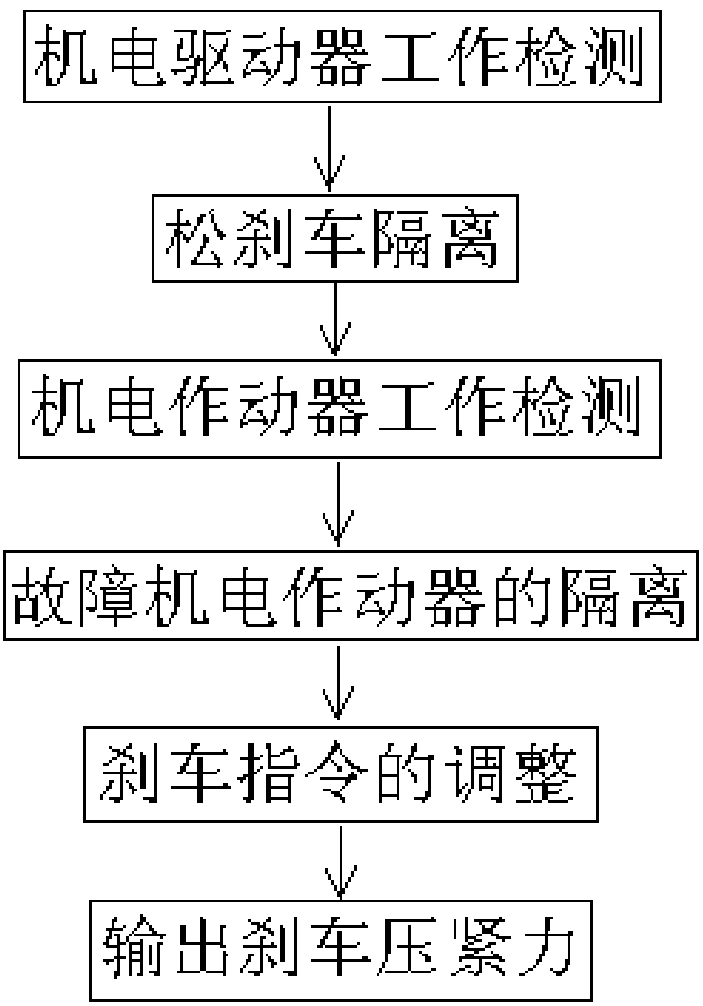

[0073] In this embodiment, when one or more of the electric brake power supply unit, the electromechanical driver, and the electromechanical actuator of the aircraft's brake control and monitoring system fails, the above-mentioned multi-wheel train aircraft electric brake electromechanical drive architecture The method for realizing braking force control, the specific process is:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com