D-shaped cross section Zig-Zig channel compact heat exchanger

A heat exchanger, compact technology, applied in the field of D-section Zig-Zag channel compact heat exchanger, can solve the problem of low effective utilization of area, difficulty in guaranteeing surface roughness grade, low heat transfer efficiency of heat exchanger, etc. problems, to achieve a wide range of pressure bearing capacity, increase the effective utilization rate, and improve the effect of heat transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with the embodiment, the technical scheme of the present invention is described in more detail:

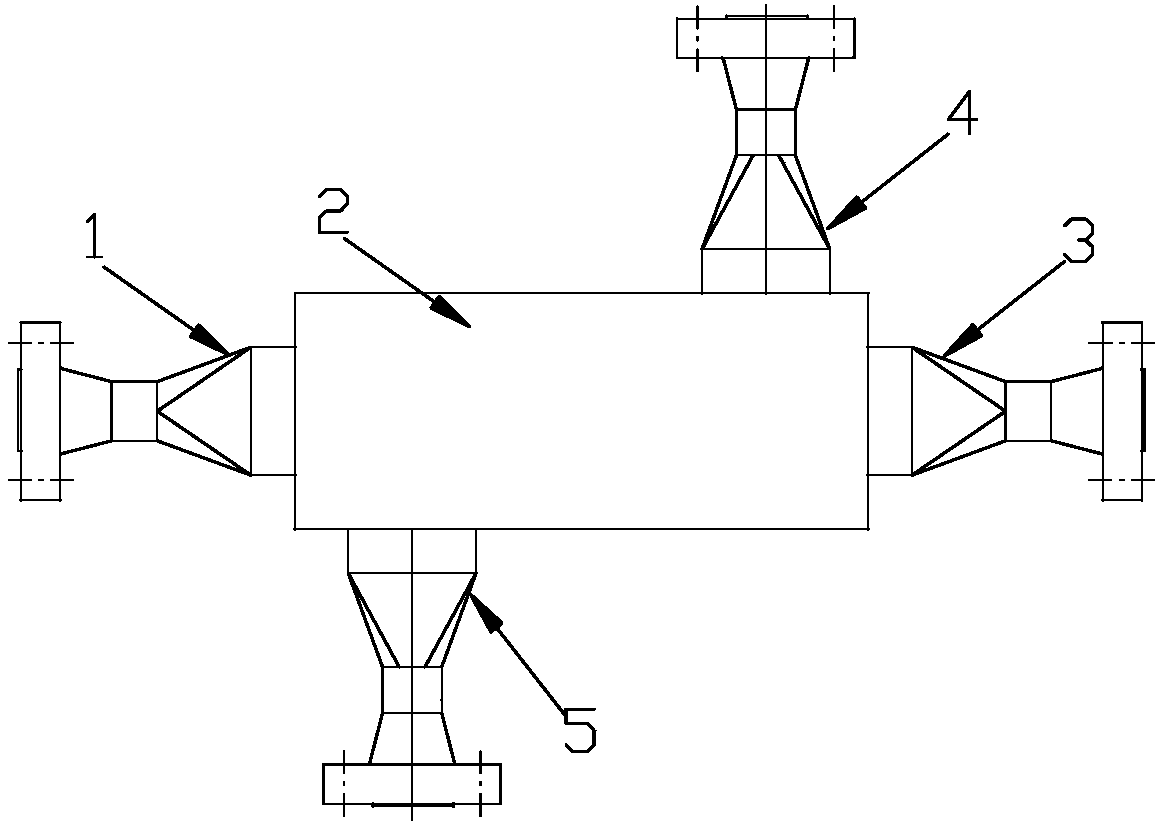

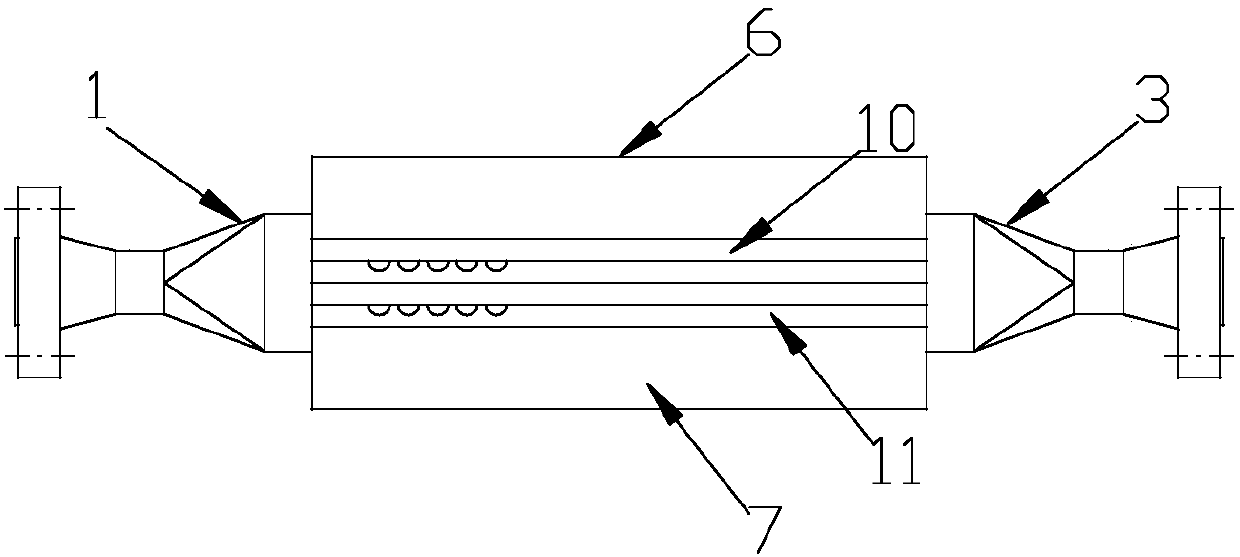

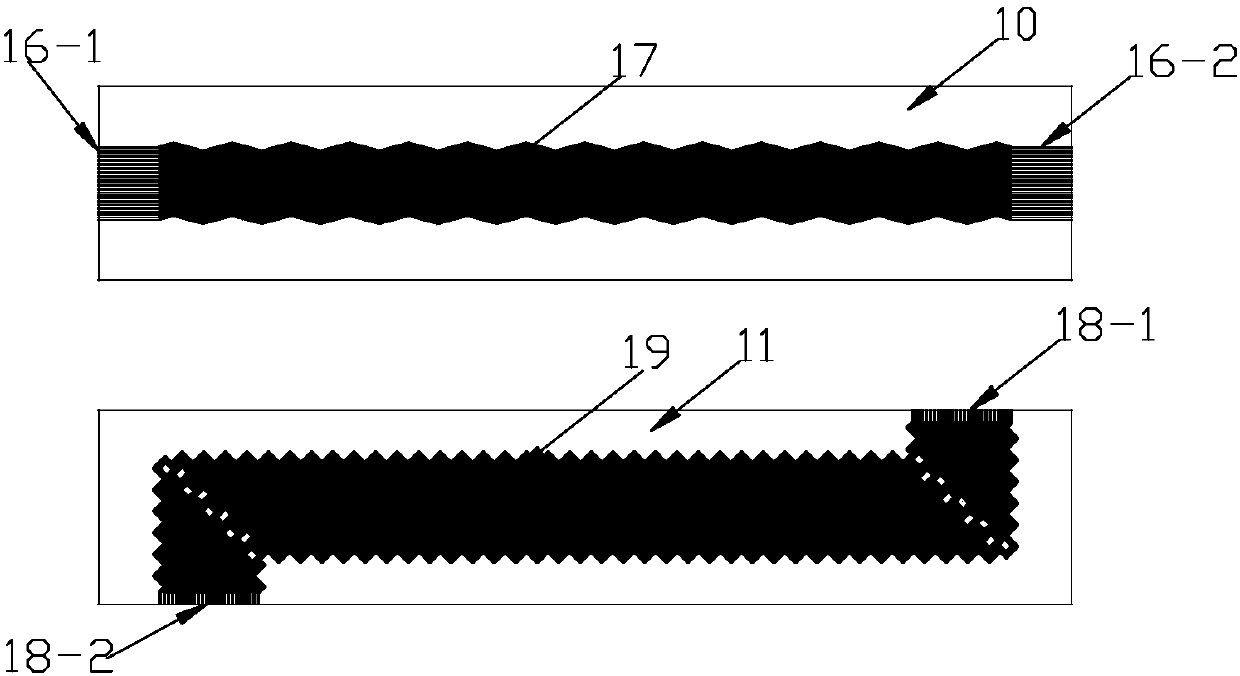

[0030] like figure 1 , 2 As shown, the present invention includes a cold fluid inlet and outlet, a hot fluid inlet and outlet, and a heat exchange core 2. The heat exchange core 2 includes a cold side plate 10 and a hot side plate 11 made of titanium or titanium alloy materials. The cold side plate 10 is etched with a plurality of juxtaposed cold side Zig-Zag channels 17 with a D-shaped cross section for the cooling fluid to pass through, and the hot side plate 11 is etched with a plurality of juxtaposed and provided The hot fluid passes through the hot side Zig-Zag channel 19 with a D-shaped cross-section. The cold side plate 10 and the hot side plate 11 are arranged in parallel and alternately overlapped and connected together by diffusion welding technology. The thickness of the hot side plate 11 is different, the cross-sectional area of the cold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com