Concrete compacting technology of urban underground shield tunneling machine

A technology of concrete and shield machine, which is applied in underground chambers, earthwork drilling, wellbore lining, etc., can solve the problems of low cost and large environmental impact, and achieve the effect of small environmental impact, fast propulsion speed, and reduced transportation cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings. However, embodiments of the present invention are not limited thereto.

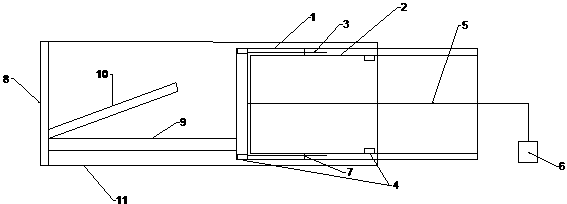

[0012] Refer to attached figure 1 When the equipment is running, the shield machine cutter head 8 excavates earth and rocks in front, and the excavated earth and rocks are transported to the outside of the tunnel through the screw conveyor 10 and the belt conveyor, and the main drive device 9 drives the shield machine forward through the hydraulic system and drags the slide The mold sleeve pouring system advances, and the shield body 11 provides a working environment for the entire shield machine and supports the earth-rock area.

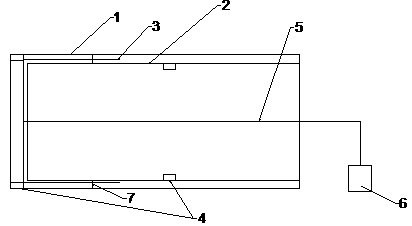

[0013] When the system is running, the working environment is excavated by the simple shield machine in front, and the concrete in the concrete pump truck 6 is pumped by the concrete pumping pipe 5 to the concrete pouring pipe 3, and the concrete pouring pipe 3 pours t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com