Method for producing semi-coke by carbonizing lump coal through vertical circular furnace

A circular furnace and vertical technology, applied in the field of coal chemical industry, can solve the problems of high water consumption, over-burning of blue carbon, and low tar oil recovery rate, and achieve accurate heating control, stable carbonization temperature, and high carbonization efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

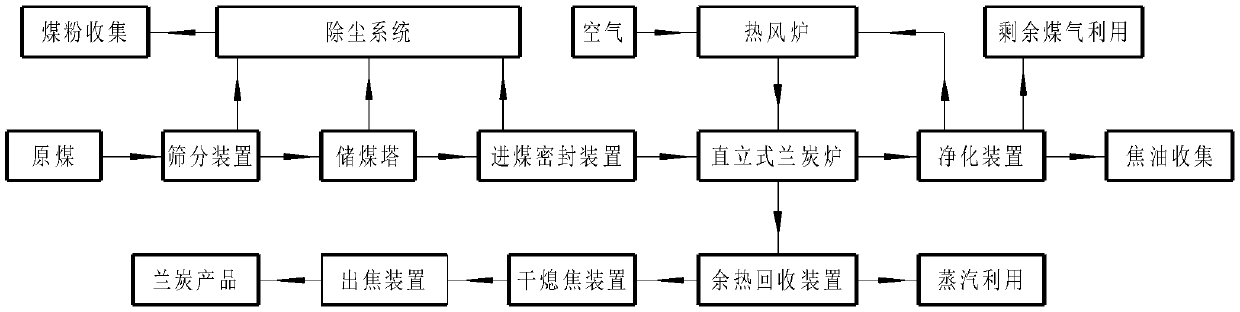

Image

Examples

Embodiment 1

[0048] The sieved lump coal with a particle size of 150mm is sent into the vertical circular furnace at a rate of 150Kg / h through the coal feeding sealing device, and is kept in the drying section at a temperature of 120-350°C (the temperature in the drying section decreases gradually from bottom to top) ) preheating and drying for 150 minutes to remove the moisture contained in the lump coal. The dried lump coal falls to the carbonization section of the vertical circular furnace. The carbonization section of the furnace body has a two-stage heating structure. A cross-shaped wall is built in the middle of the furnace body of the carbonization section. There are air ducts; each heating section is equipped with 8 uniformly distributed high-temperature flue gas inlets corresponding to the outer wall of the furnace body circumference and the end of the cross flower wall, and 6 layers of air outlets are set on the inner wall of the furnace body circumference and the cross flower wal...

Embodiment 2

[0057]The sieved lump coal with a particle size of 70mm is sent into the vertical circular furnace at a rate of 200Kg / h through the coal feeding sealing device. In the drying section at a temperature of 110-350°C (the drying section temperature gradually decreases from bottom to top) ) preheating and drying for 105 minutes to remove the moisture contained in the lump coal. The dried lump coal falls to the carbonization section of the vertical circular furnace. The carbonization section of the furnace body has a two-stage heating structure. A cross-shaped wall is built in the middle of the furnace body of the carbonization section. There are air ducts; each heating section is equipped with 8 uniformly distributed high-temperature flue gas inlets corresponding to the outer wall of the furnace body circumference and the end of the cross flower wall, and 6 layers of air outlets are set on the inner wall of the furnace body circumference and the cross flower wall of the correspondin...

Embodiment 3

[0066] The sieved lump coal with a particle size of 20mm is sent into the vertical circular furnace at a rate of 300Kg / h through the coal inlet sealing device, and is kept at a temperature of 100-350°C in the drying section (the temperature in the drying section decreases gradually from bottom to top) ) preheating and drying for 60 minutes to remove the moisture contained in the lump coal. The dried lump coal falls to the carbonization section of the vertical circular furnace. The carbonization section of the furnace body has a two-stage heating structure. A cross-shaped wall is built in the middle of the furnace body of the carbonization section. There are air ducts; each heating section is equipped with 8 uniformly distributed high-temperature flue gas inlets corresponding to the outer wall of the furnace body circumference and the end of the cross flower wall, and 6 layers of air outlets are set on the inner wall of the furnace body circumference and the cross flower wall of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com