Multi-layer structure-based millimeter wave array antenna

A multi-layer structure and array antenna technology, which is applied in the field of antenna and wireless communication, can solve the problems of unfavorable array antenna miniaturization and high gain design, shorten the length of the horn opening, and large antenna size, so as to shorten the length of the horn antenna and avoid parasitic Radiation, effect of reducing insertion loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

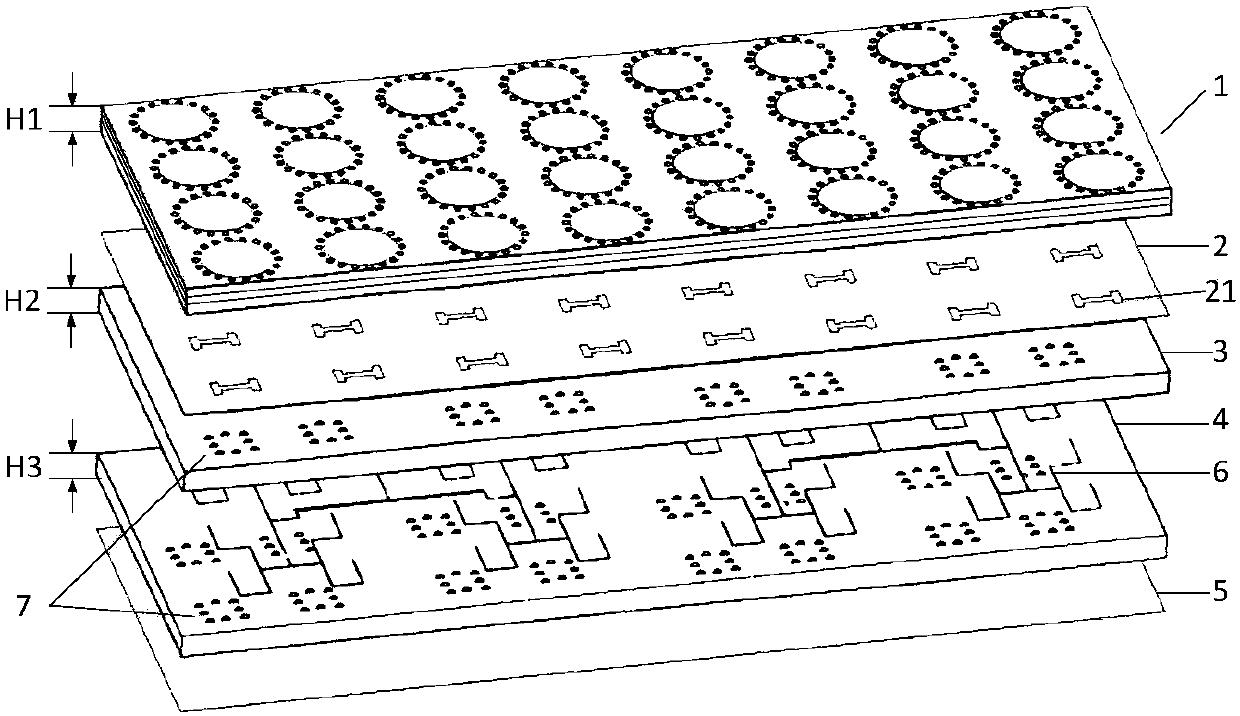

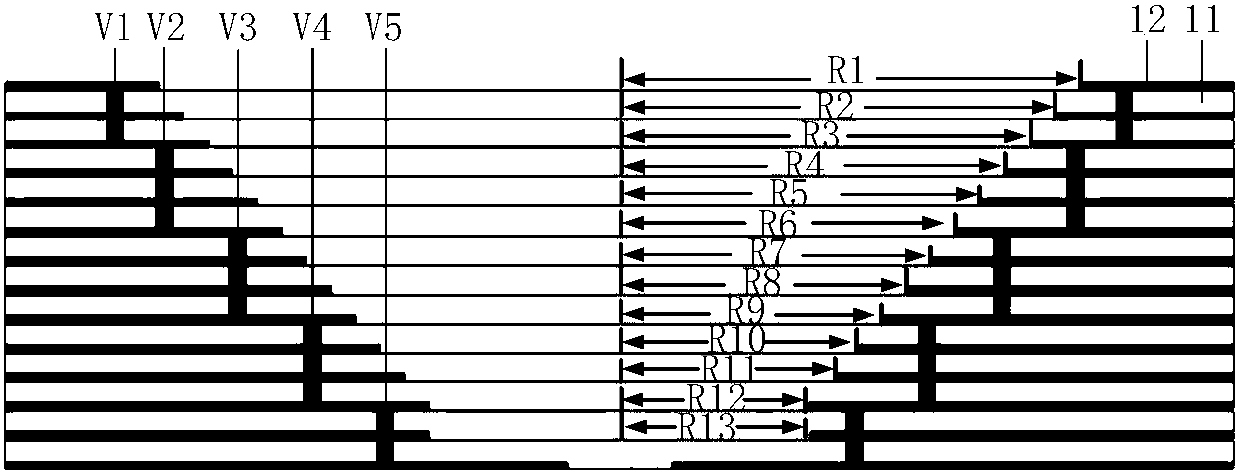

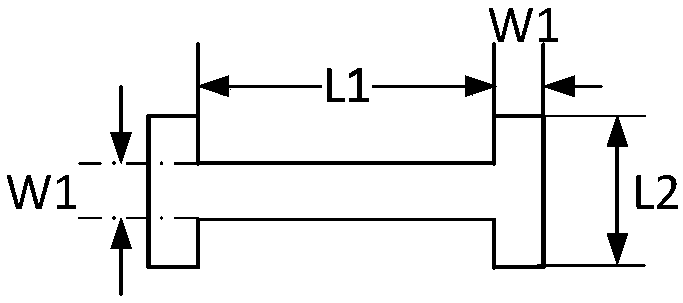

[0023] refer to figure 1 , a millimeter-wave array antenna based on a multilayer structure, including 4×8 antenna units 1, a first dielectric plate 3 and a second dielectric plate 4 stacked up and down, the thickness of the antenna unit 1 is H1=1.248mm, The thickness of the first dielectric board is H2=0.096mm, the thickness of the second dielectric board is H3=0.48mm, the upper surface of the first dielectric board 3 is printed with an internal grounding plate 2, and the second An external grounding plate 5 is printed on the lower surface of the dielectric plate 4, and 4×8 radiation slots 21 are etched on the internal grounding plate 2, such as image 3 As shown, the antenna unit 1 is fixed on the internal ground plate 2, and is located directly above the radiation slot 21, as Figure 5 As shown, a feed network 6 is provided between the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com