A Method of Using Cartridge Logic Valve to Realize Hydraulic Control of Pulling and Straightening

A logic valve and plug-in technology, which is applied in the direction of fluid pressure actuators, servo motor components, mechanical equipment, etc., can solve the problems of small diameter of plate valve parts, large tension and straightening hydraulic system, and slow response speed. Achieve the effects of reduced structure, less internal leakage and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solutions of the present invention will be further described below through specific embodiments in conjunction with the accompanying drawings.

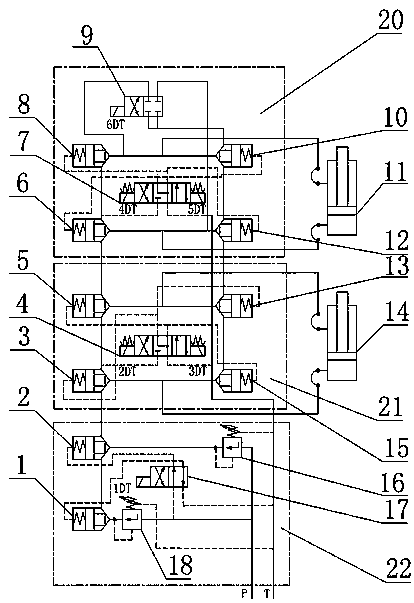

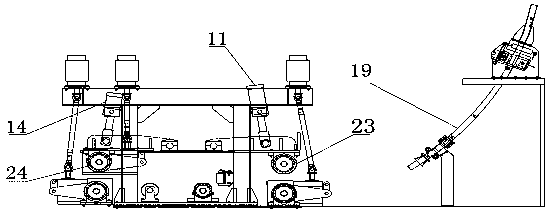

[0014] Such as figure 1 As shown, the present invention uses a plug-in logic valve to realize the hydraulic control method for tension leveling. The hydraulic control method for tension leveling of each stream of the continuous casting machine is the same, and they are all combined with functional integrated blocks using a cascading connection. Each stream has three functions. Manifolds, from bottom to top, are the decompression logic valve manifold 22, the billet drawing logic valve manifold 21, and the stripping logic valve manifold 20. The decompression logic valve manifold 22 is composed of a plug-in logic valve 1, a plug-in logic valve 2, a low-pressure pressure relief valve 16, a two-position four-way reversing valve 17, and a high-pressure pressure relief valve 18. The reversing valve 17 is a high-pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com