Flow separation, pressure adjustment and speed adjustment reversing integrated valve

A technology of pressure regulation and speed regulation, integrated valve, applied in the direction of fluid pressure actuation device, servo motor assembly, mechanical equipment, etc., can solve the problems of high manufacturing cost and failure rate, waste of energy, temperature rise of working medium, etc. And the effect of reducing operation and maintenance costs, reducing system failure rate, and solving excessive temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be further described below in conjunction with the examples, but it should not be interpreted as a limitation of the present invention. The protection scope of the present invention is based on the contents recorded in the claims. protection scope of the present invention.

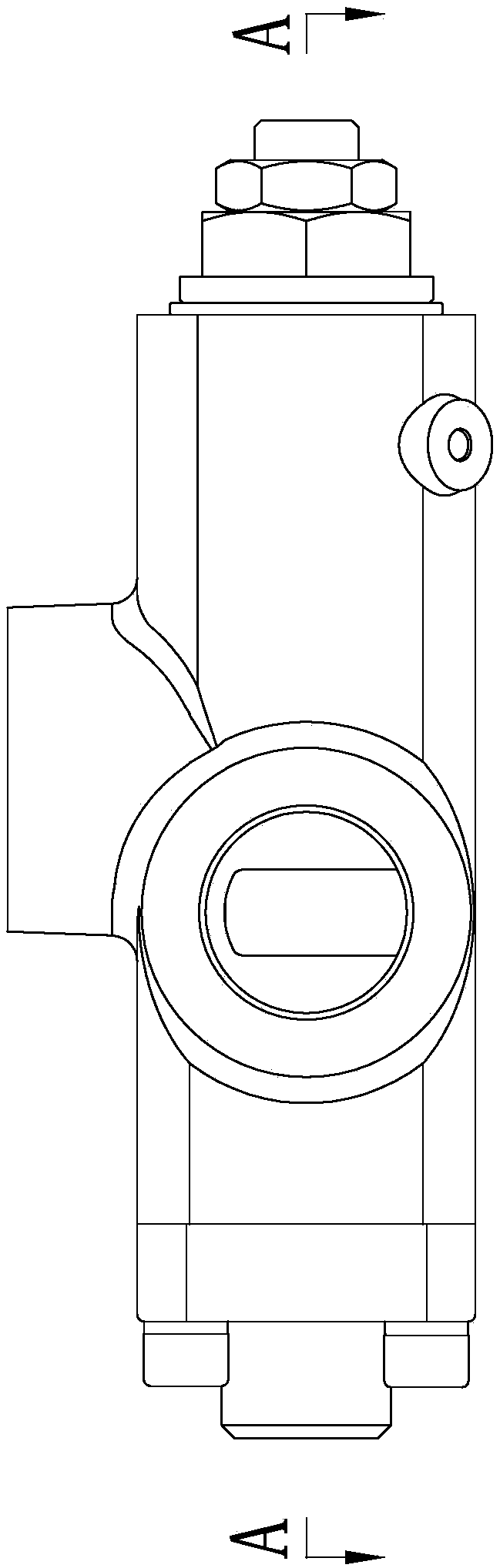

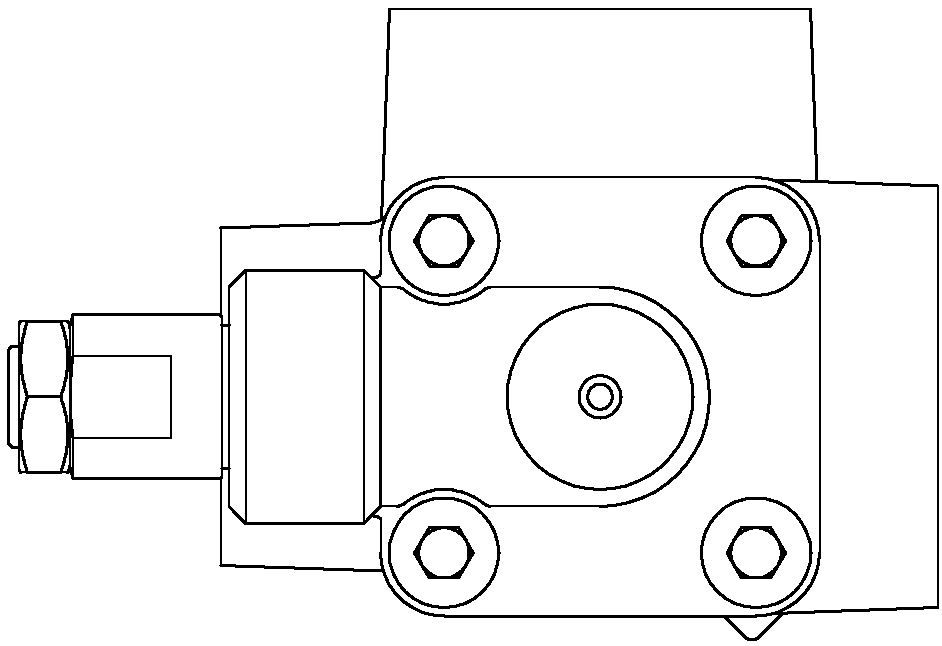

[0059] The overall structure of this embodiment is shown in the figure, which includes a valve body 10, an oil inlet P opened on the valve body 10, the oil inlet P is connected to the oil inlet chamber PQ, and a relief valve is inserted on the valve body 10; 10 is provided with an oil return port T, a throttle oil outlet FL, and an oil outlet ZL. The valve body 10 is successively separated from left to right with an overflow back pressure chamber BQ and an oil outlet chamber ZQ axially penetrated by the main hole 4. , oil inlet chamber PQ, fuel saving oil outlet chamber FQ, hydraulic control chamber YQ; throttle outlet chamber FQ connects with throttle outlet FL, oil outle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com