Preparing method for lightweight wall

A light-weight wall and wall technology, applied in the direction of walls, building components, climate change adaptation, etc., can solve the problems of large amount of resin, high temperature resistance, resin curing, etc., to improve service life, excellent sound insulation performance, overall high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

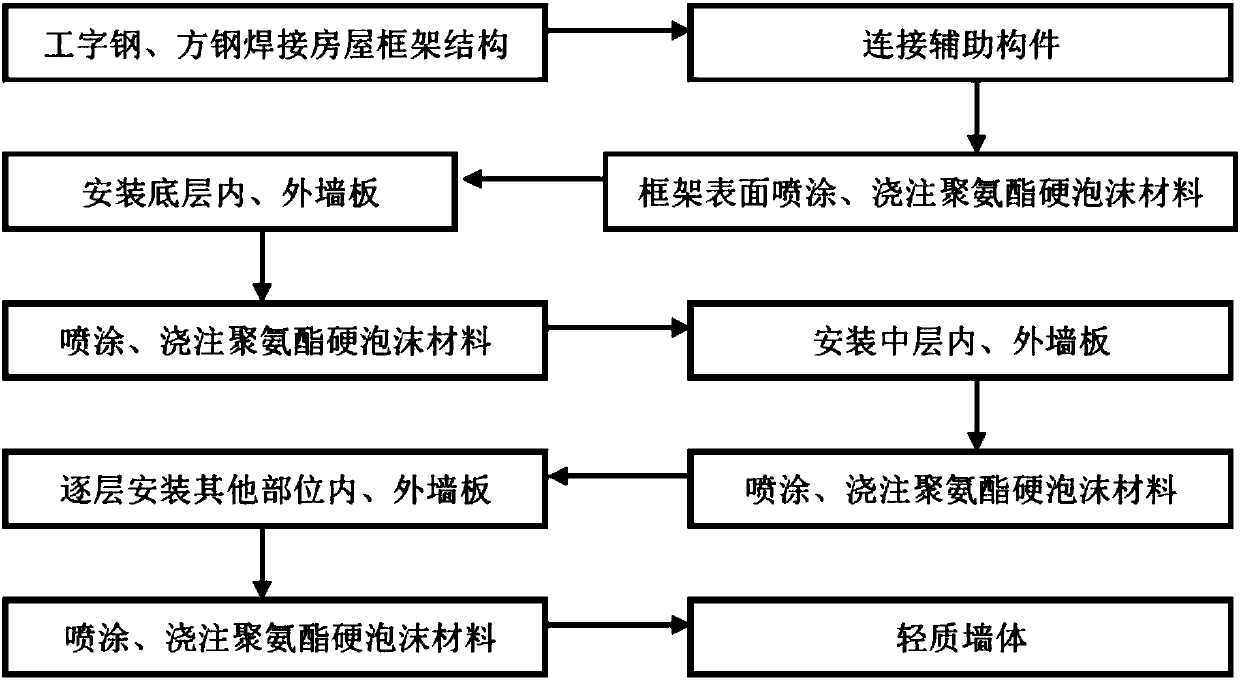

[0058] Such as Figures 1 to 4 As shown, the invention provides a kind of preparation method of lightweight wall, comprising:

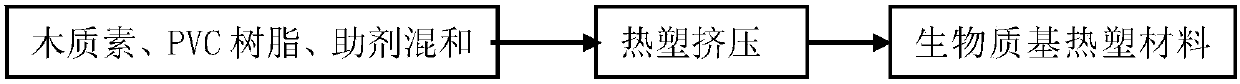

[0059] Step 1. According to the design of the house structure, firstly, use the I-beam or square steel material to make the main frame of the house structure. Biomass-based thermoplastic material as a fine-grid frame;

[0060] Step 2, first connecting the auxiliary components used to connect the inner and outer wall panels to the main frame of the building structure, and then connecting the bottom inner and outer wall panels to the auxiliary components;

[0061] Step 3. Pouring or spraying the biomass-based polyurethane rigid foam material into the cavities of the inner and outer wall panels of the bottom layer, making it compatible with the inner and outer wall panels of the bottom layer and the main frame and auxiliary structure of the house structure here. The members form a dense lower wall;

[0062] Step 4. After forming the lower wall, instal...

Embodiment 1

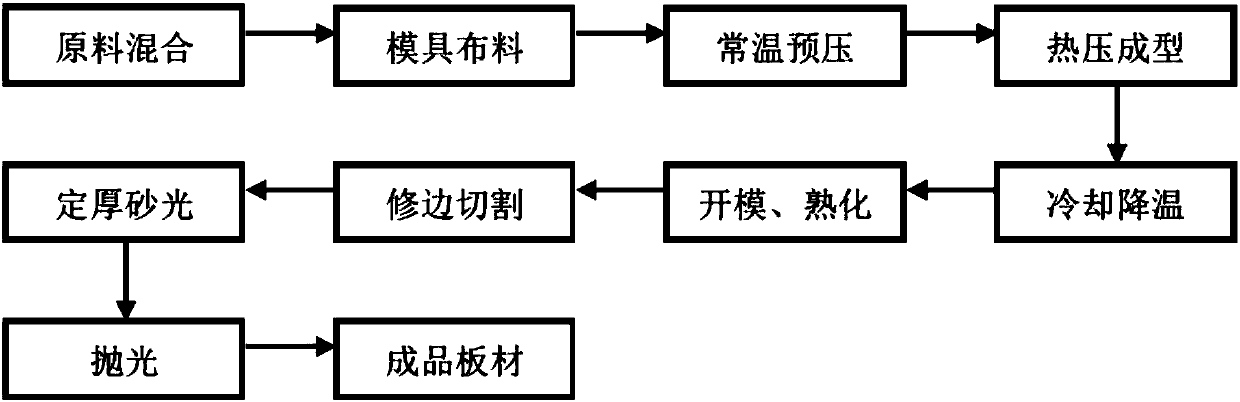

[0098] 1) Specific steps and parameters of the plate process:

[0099] 1), raw materials

[0100] In terms of parts by mass, one or more selected and crushed 40-mesh colored stones are selected as the waste stone, 50 parts;

[0101] The cement is ordinary Portland cement P.O 32.5, 10 parts;

[0102] Mica powder is selected from one or more of 40 meshes of various colored mica powders, 20 parts;

[0103] The resin powder is thermosetting phenolic resin powder, 6 parts.

[0104] 2), mold

[0105] According to the requirements of plates of different specifications, 65Mn carbon steel molds with covers of different specifications are self-made, and all surfaces of the molds are polished and polished. Spread a layer of straw paper or kraft paper of appropriate specifications on the mold bottom plate (12mm thick 65Mn carbon steel) before fabricating, and install four detachable mold frames (the mold frame is 15*15mm 65Mn carbon steel square steel, according to different Assembli...

Embodiment 2

[0154] 1) Specific steps and parameters of the plate process:

[0155] 1), raw materials

[0156] In terms of parts by mass, one or more selected and crushed 200-mesh colored stones are selected as the stone waste, 80 parts;

[0157] The cement is white Portland cement P.W 32.5, 20 parts;

[0158] The sand is selected from washed dry fine river sand, 20 parts;

[0159] The resin powder is thermosetting phenolic resin powder, 8 parts.

[0160] 2), mold

[0161] According to the requirements of plates of different specifications, 65Mn carbon steel molds with covers of different specifications are self-made, and all surfaces of the molds are polished and polished. Spread a layer of straw paper or kraft paper of appropriate specifications on the mold bottom plate (12mm thick 65Mn carbon steel) before fabricating, and install four detachable mold frames (the mold frame is 15*15mm 65Mn carbon steel square steel, according to different Assembling the appropriate number of layers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com