A kind of preparation method of water-based anti-ultraviolet finishing liquid based on illite mineral

An anti-ultraviolet, finishing liquid technology, applied in fiber treatment, coating, textile and papermaking, etc., can solve the problems of easy agglomeration, high production cost, high photocatalytic activity, and overcome the problems of coarse particles, low cost and simple production process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

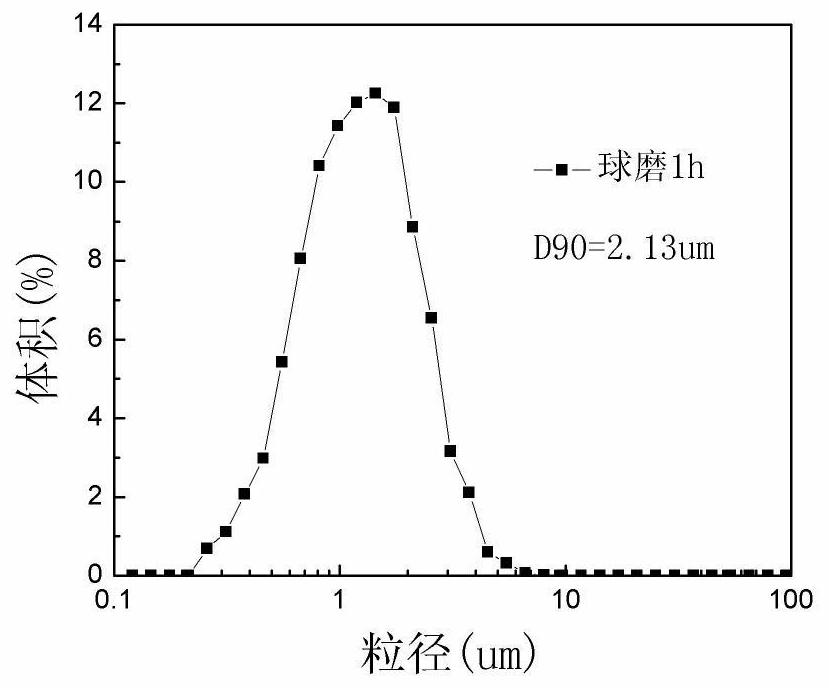

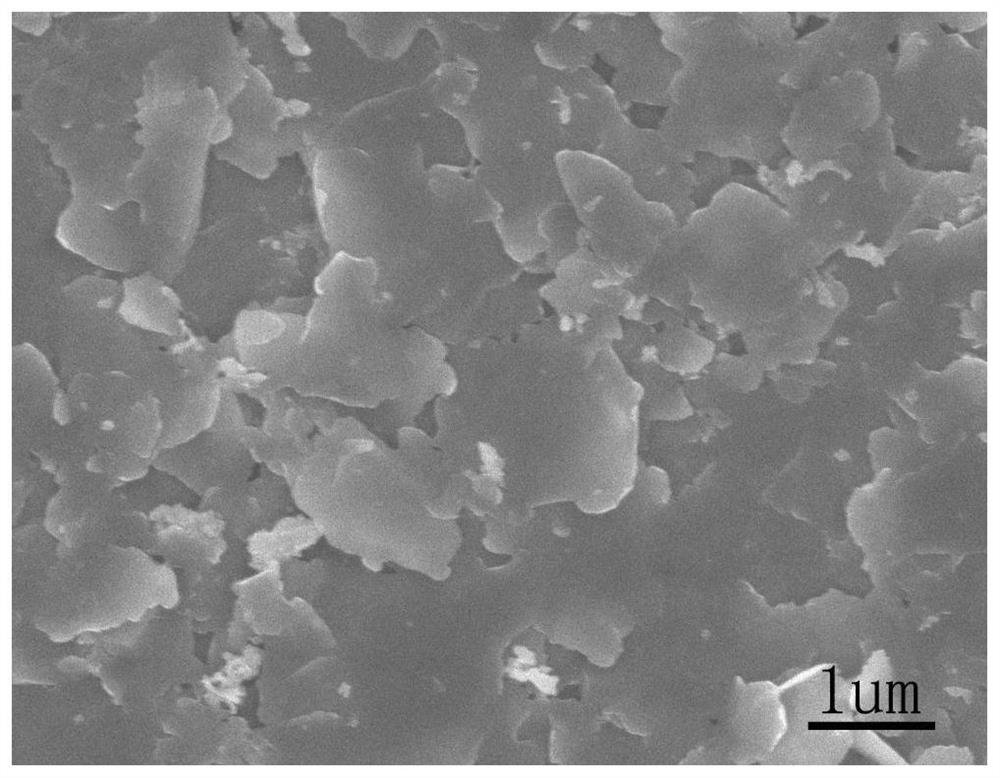

Embodiment 1

[0020] Pulverize the Jilin Antu illite ore and add water to make a suspension with a mass fraction of 20%. After fully stirring, let it stand for 48 hours. 1h, let stand for 1h. Take 100mL of the supernatant liquid and place it in a ball mill jar, then weigh 200g of zirconia large balls (Φ3) and 100g of zirconia small balls (Φ2.2) into the jar, stir well to make them evenly mixed. Afterwards, ball milling was carried out at a speed of 1200 r / min, and a high-purity ultrafine illite solution was obtained after ball milling for 1 hour. The UV-Vis ultraviolet transmittance test was carried out on the above sample, and the results showed that it could shield 52% of UVA, 59% of UVB and 68% of UVC. Then add water to the above-mentioned high-purity ultrafine illite solution to prepare a suspension with a solid content of 20 g / L, add 0.1 g of HPMC at the same time, and magnetically stir for 12 hours to obtain an anti-ultraviolet finishing solution. Put the fabric in the finishing pro...

Embodiment 2

[0022] Grind Jilin Antu illite raw ore and add water to make a suspension with a mass fraction of 10%. After stirring fully, let it stand for 48 hours. 1h, let stand for 1h. Take 100mL of the supernatant liquid and place it in a ball mill jar, then weigh 250g of zirconia large balls (Φ3) and 100g of zirconia small balls (Φ2.2) into the jar, stir well to make them evenly mixed. Afterwards, ball milling was carried out at a speed of 1200 r / min, and a high-purity ultrafine illite solution was obtained after ball milling for 2 hours. The UV-Vis ultraviolet transmittance test was carried out on the above sample, and the results showed that it could shield 44% of UVA, 51% of UVB and nearly 60% of UVC. Then add water to the above-mentioned high-purity ultrafine illite solution to prepare a suspension with a solid content of 10 g / L, add an appropriate amount of polyethylene glycol at the same time, and magnetically stir for 12 hours to prepare an anti-ultraviolet finishing solution. ...

Embodiment 3

[0024] Pulverize the Jilin Antu illite raw ore and add water to make a suspension with a mass fraction of 20%. After fully stirring, let it stand for 48 hours. 1h, let stand for 1h. Take 100mL of the supernatant liquid and place it in a ball mill jar, then weigh 200g of zirconia large balls (Φ3) and 150g of zirconia small balls (Φ2.2) into the jar, stir well to make them evenly mixed. Afterwards, ball milling was carried out at a speed of 1200 r / min, and a high-purity ultrafine illite solution was obtained after ball milling for 1 hour. The UV-Vis ultraviolet transmittance test was carried out on the above sample, and the results showed that it could shield 45% of UVA, 53% of UVB and 62% of UVC. Then add water to the above-mentioned high-purity ultrafine illite solution to prepare a suspension with a solid content of 20 g / L, and add an appropriate amount of HPMC at the same time, and magnetically stir for 12 hours to prepare an anti-ultraviolet finishing solution. Put the fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com