High-power neutral electrolyte metal-air battery system and using method thereof

An air battery and electrolyte technology, which is used in electrolyte flow treatment, fuel cell additives, fuel cell type half cells and primary cell type half cells, etc. The temperature of the plate rises and the internal cleaning of the battery is difficult to achieve the effect of low cost, cutting off the load at any time, and easy start-up and use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

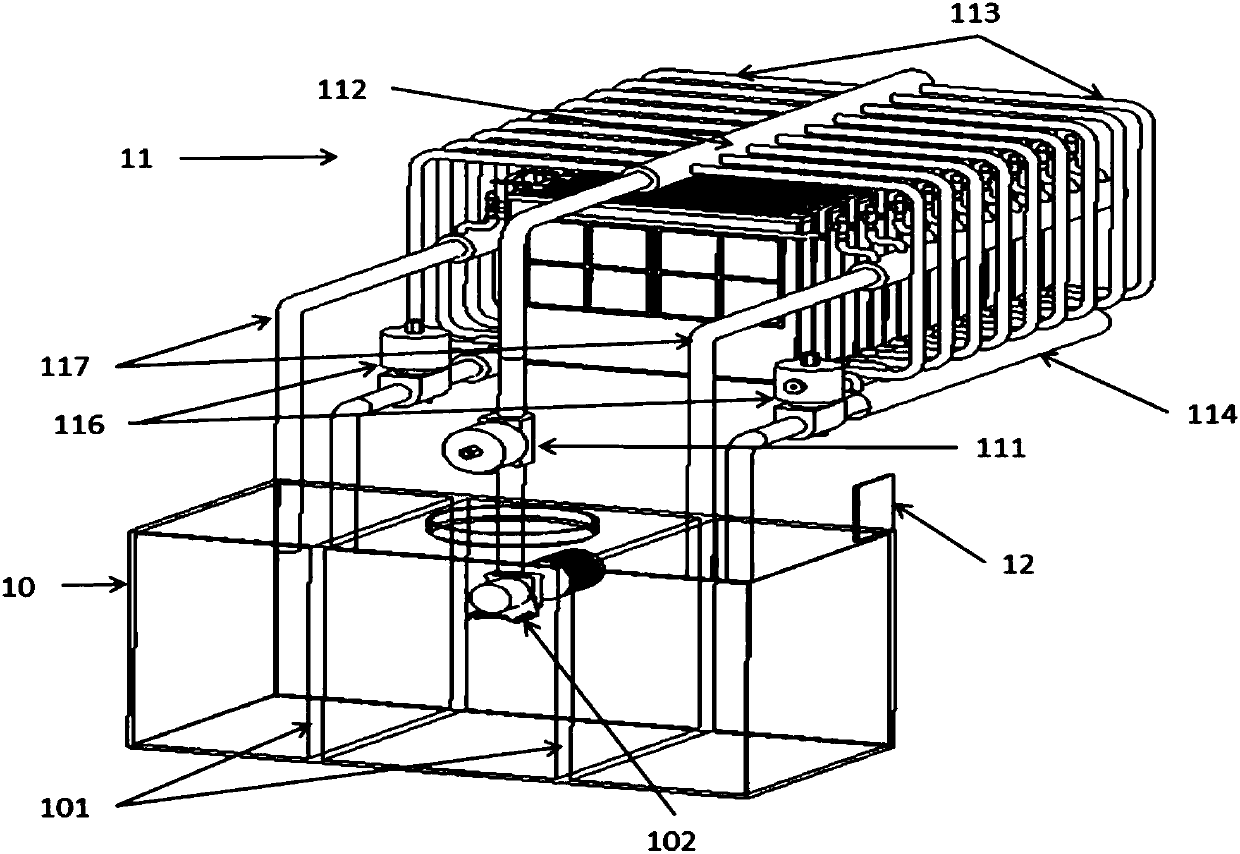

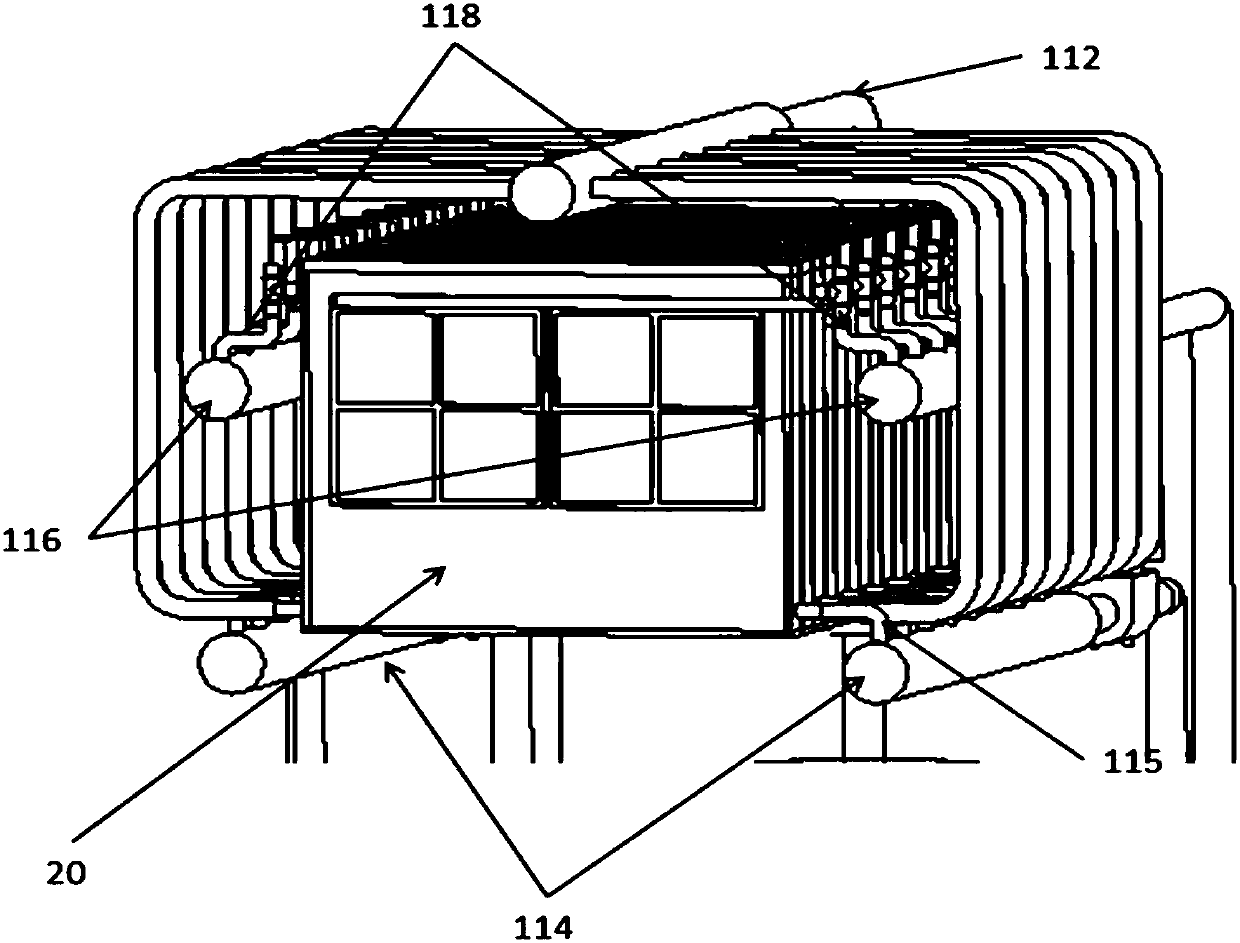

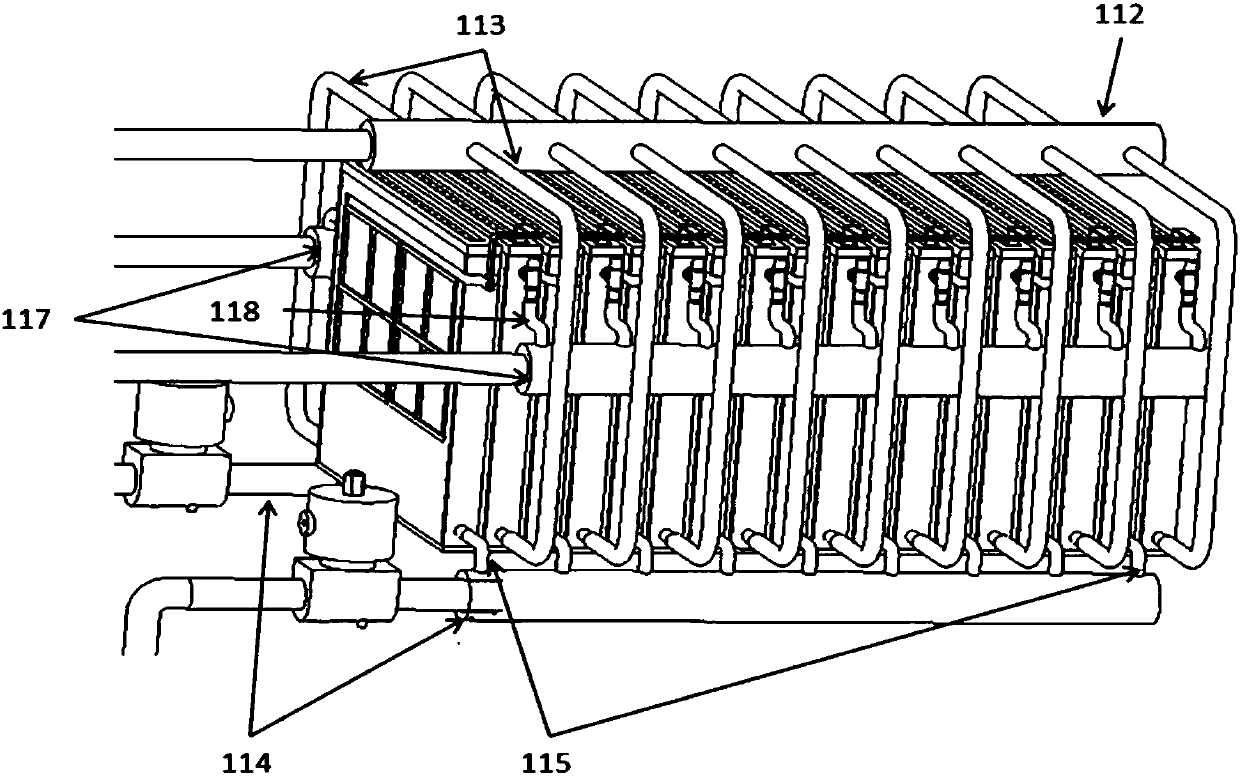

[0030] A high-power neutral electrolyte metal-air battery system. The battery system is composed of two or more (series or parallel) basic battery cells 20, an electrolyte filter box 10, a circulation pump 102, a control valve 111, an electrolyte input distributor 112, an electrolyte discharge manifold 114, and a drain valve 117. The electrolyte overflow manifold 116, the control circuit 12, the controller and the connecting pipeline are composed. The basic battery unit is composed of a reaction box 200, an anode 203, a cathode 201, an electrolyte, a cathode busbar 202, and an anode busbar 204. Both sides of the reaction box are provided with an electrolyte input port 207, an electrolyte outlet port 206, and an electrolyte overflow. Exhaust port 208 .

Embodiment 2

[0032] In the high-power neutral electrolyte metal-air battery system, the metal-air battery is composed of at least two basic battery cells 20 that are electrically connected in series or parallel to each other to form a battery pack 11 . When the battery pack 11 is running, the control valve 111 is opened, and the circulating pump 102 located in the circulating filter box 10 pumps the filtered electrolyte into the battery pack 11 . An electrolyte input distributor 112 is arranged above the battery pack 11 , and the electrolyte input distributor 112 sends the electrolyte into the electrolyte input ports 207 of each reaction box 200 respectively through the electrolyte input communication pipe 113 . The excess electrolyte in the reaction box 200 is input, and discharged to the electrolyte overflow manifold 117 through the electrolyte overflow pipe 118 through the electrolyte overflow exhaust port 208 on the upper part of the reaction box 200 . The electrolyte overflowing from ...

Embodiment 3

[0034] The use method of the air battery includes the following steps:

[0035] Step A: Open the control valve 111, under the driving of the circulating pump 102, the pre-filtered electrolyte is pumped into the electrolyte input distributor 112, and then respectively flows into the reaction box 200 of each basic battery unit 20, according to the temperature of the electrolyte. Control the switch of the drain valve 116 to discharge the high-temperature electrolyte and the reaction residue in the reaction box 200 to the filter box 10;

[0036] Step B: start the circulating pump 102 to pump the electrolyte into the reaction box 200 through the water inlet pipe, control the water level of the reaction box 200, after all the water levels of the reaction boxes 200 have reached the working water level, start the drain valve 116 of the battery system to produce in the reaction process. The resulting reaction residues together with the electrolyte are led out to the filter box 10 through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com