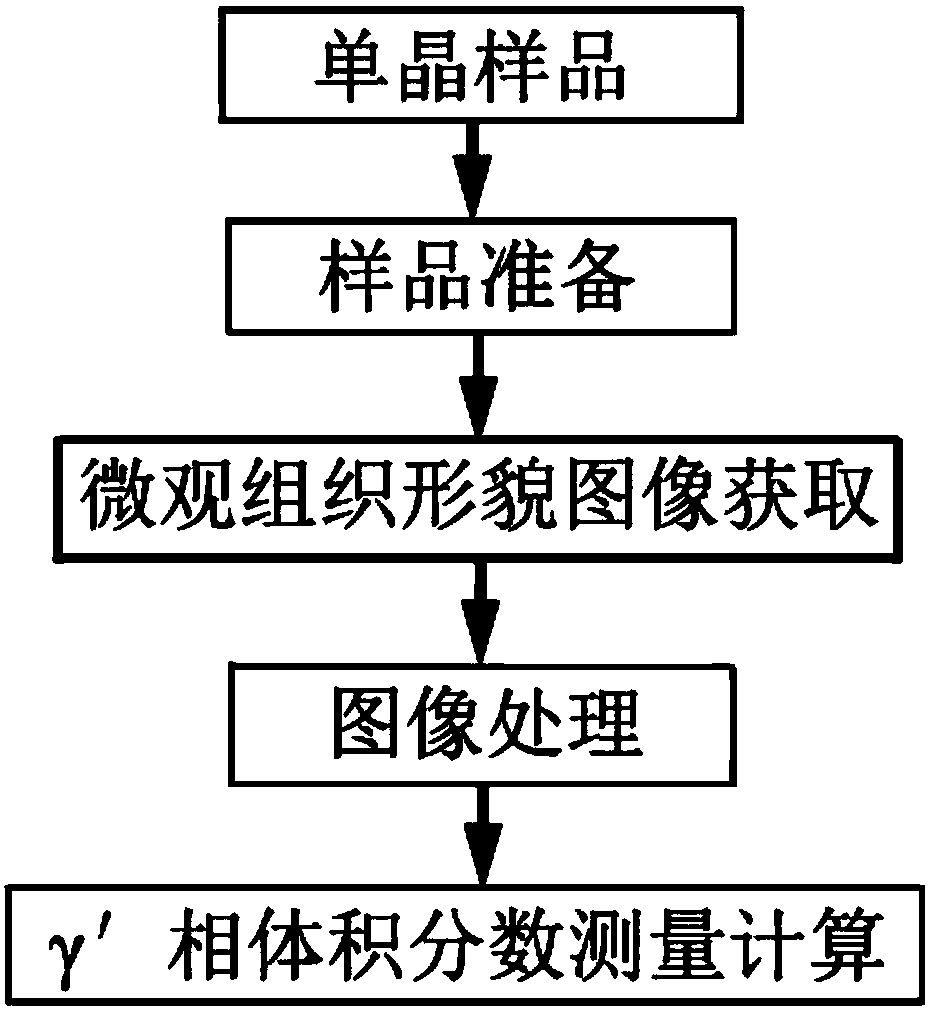

Method for measuring volume fraction of gamma' phase in nickel-based single crystal superalloy

A high-temperature alloy, nickel-based single crystal technology, applied in measurement devices, analysis materials, material analysis using wave/particle radiation, etc., can solve problems such as large errors and poor repeatability, and achieve small errors, simple operation, and simple configuration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0066] Experimental Alloy CMSX-10.

[0067] a) Sample preparation

[0068] The nickel-based superalloy samples that need to be detected and analyzed are intercepted by wire cutting, and the oil stains remaining on the surface of the samples during the cutting process are cleaned with acetone or alcohol. After the samples are ground and polished, they are made of HNO with a volume ratio of 1:2:3. 3 , HF and C 3 h 5 (OH) 3 The mixed solution is used for corrosion treatment.

[0069] b) Acquisition of microstructure and morphology images of nickel-based superalloys

[0070] The processed sample was magnified 10,000 to 50,000 times with a ZEISS SUPRA 55 field emission scanning electron microscope to observe the morphology and distribution of the γ′ phase, and the microstructure image was obtained with the camera of the scanning electron microscope system.

[0071] c) Image processing

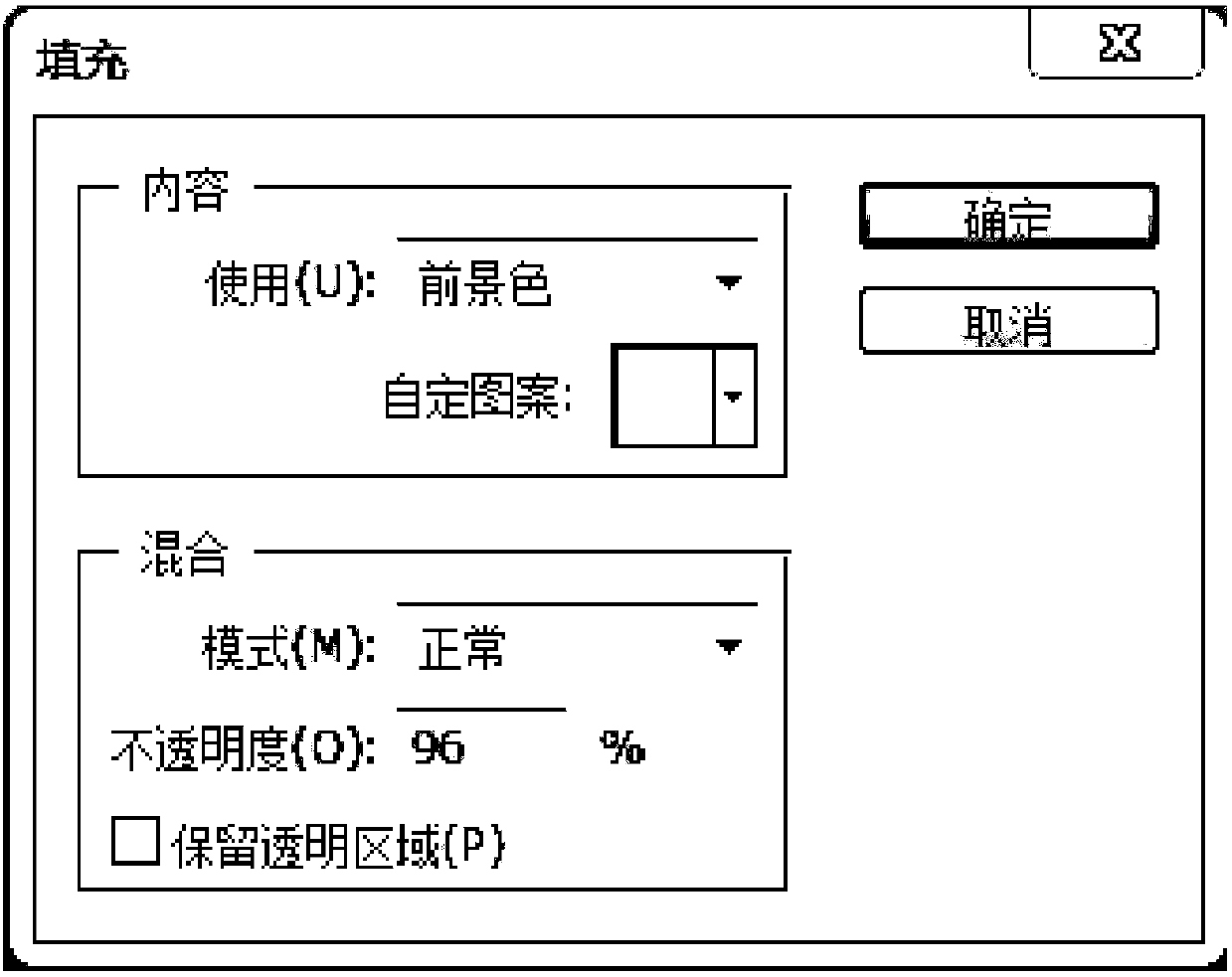

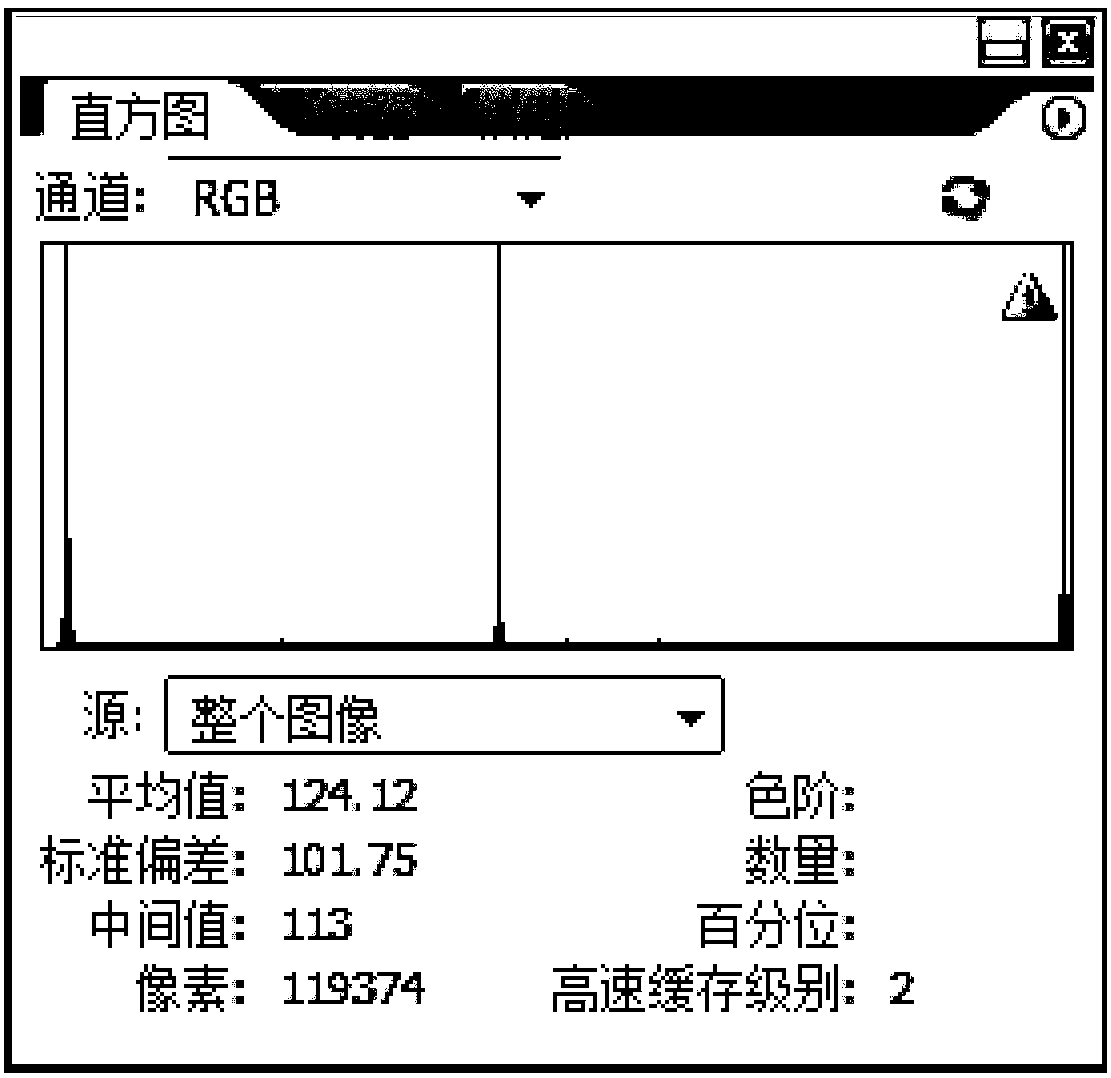

[0072] Using Adobe Photoshop CS2 software, all γ′ phases in the microstructure topography ...

Embodiment 3

[0086] Experimental alloy DD403.

[0087] a) Sample preparation

[0088] The nickel-based superalloy sample that needs to be detected and analyzed is intercepted by wire cutting, and the oil stain remaining on the surface of the sample during the cutting process is removed by cleaning with acetone or alcohol. After the sample is ground and polished, it is made of HNO with a volume ratio of 1:2:3. 3 , HF and C 3 h 5 (OH) 3 The mixed solution is used for corrosion treatment.

[0089] b) Acquisition of microstructure and morphology images of nickel-based superalloys

[0090] The processed sample was magnified 10,000 to 50,000 times with a ZEISS SUPRA 55 field emission scanning electron microscope to observe the morphology and distribution of the γ′ phase, and the microstructure image was obtained with the camera of the scanning electron microscope system.

[0091] c) Image processing

[0092] Using Adobe Photoshop CS2 software, all γ′ phases in the microstructure topography...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com