Noble-metal nanoparticle-loading metal-organic framework, preparation method and application

A technology of metal-organic frameworks and nanoparticles, which is applied in the direction of analysis, measuring devices, and instruments through chemical reactions of materials, can solve the problems that electrodes cannot be reused, the operation process is complicated, and there is no load, so as to improve the electrical conductivity. Poor, rapid preparation process, effect of increasing dispersion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

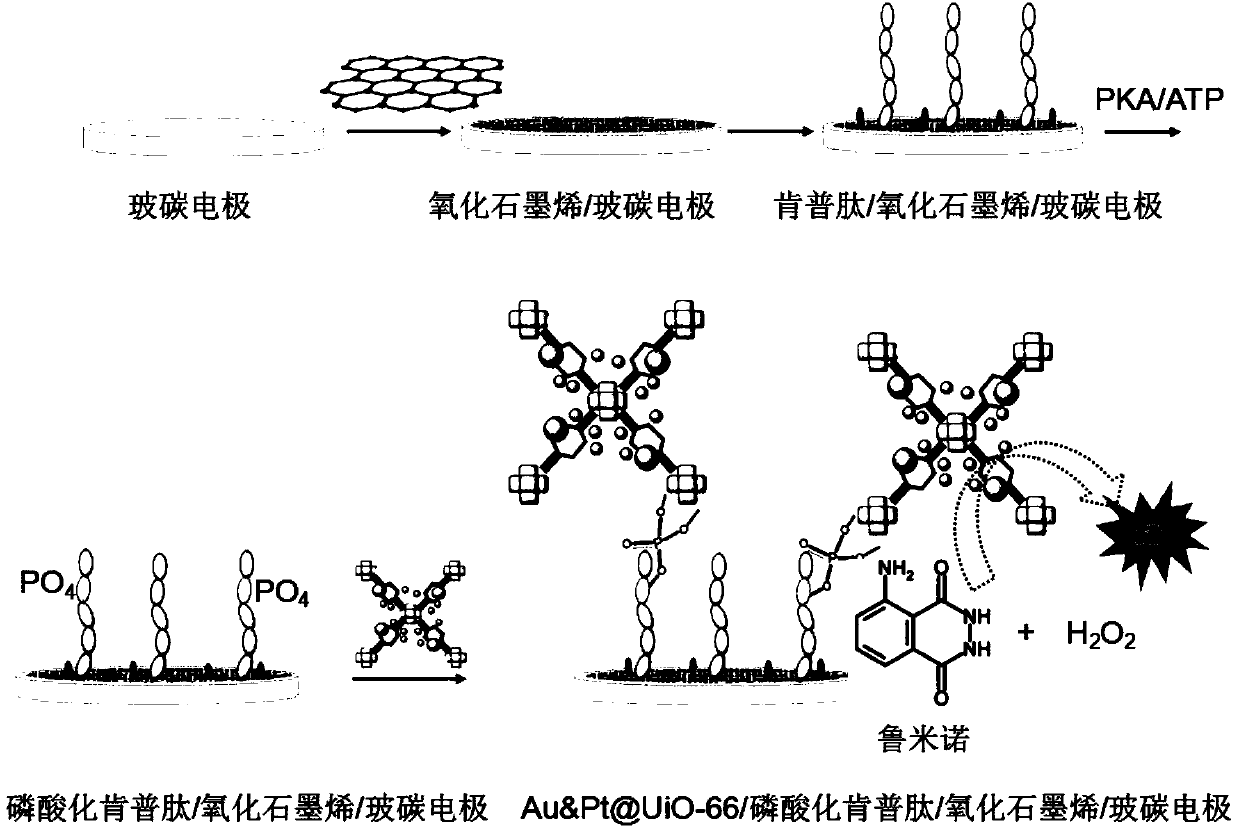

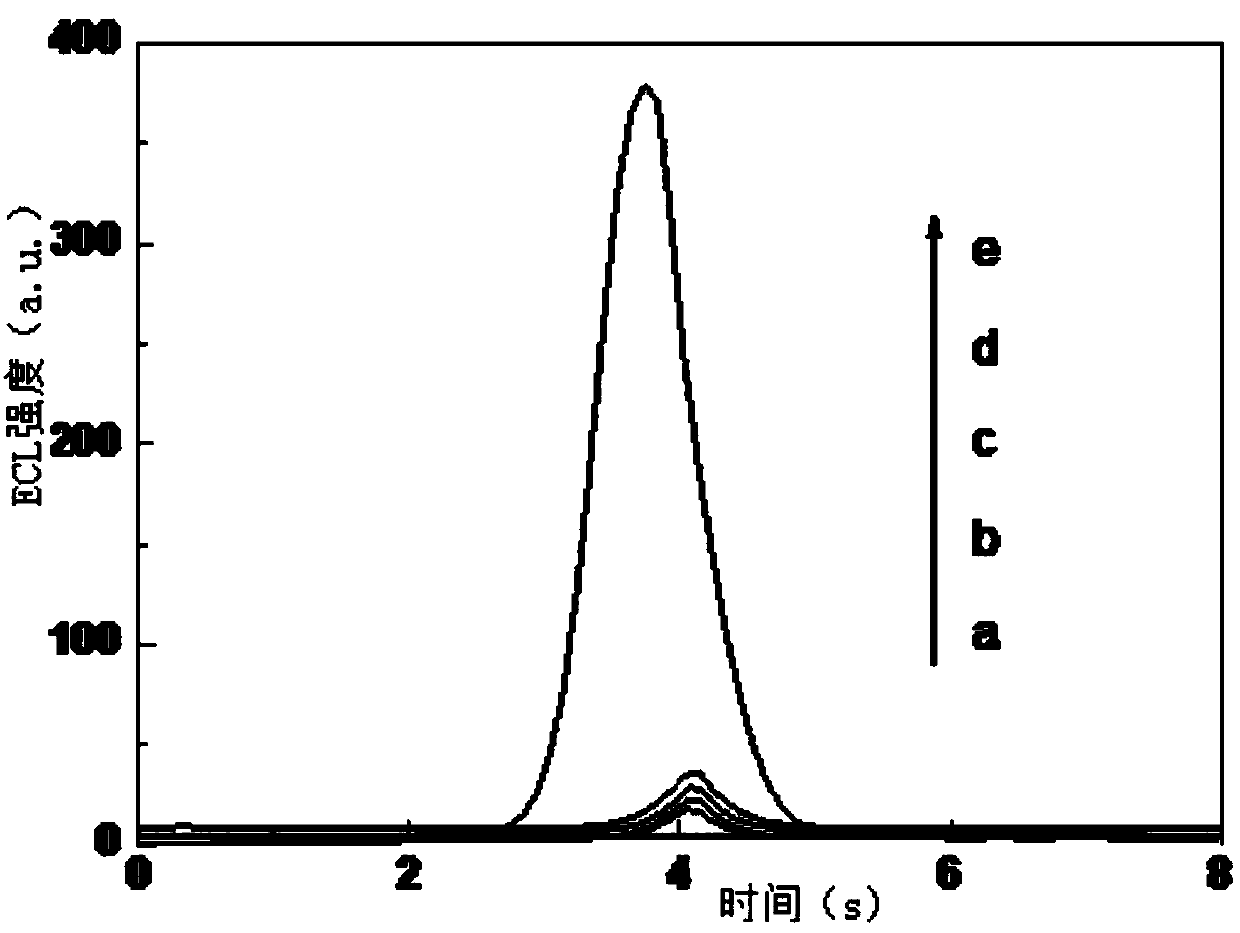

[0078] The invention provides a preparation method of a metal-organic framework composite material loaded with two or more noble metal nanoparticles, which is to first synthesize a metal-organic framework loaded with one or two kinds of noble metal nanoparticles, and then synthesize a metal-organic framework loaded with another noble metal nanoparticle. Particle method, preparing a metal-organic framework composite material loaded with two or more noble metal nanoparticles, and then using the prepared metal-organic framework composite material loaded with two or more noble metal nanoparticles to construct an electrochemiluminescent sensor , for the analysis of protein kinase activity and the screening of protein kinase inhibitors.

[0079] In a preferred specific embodiment of the present invention, a method for preparing a metal-organic framework composite material loaded with two or more noble metal nanoparticles is provided, which comprises the following steps:

[0080] (1)...

Embodiment 1

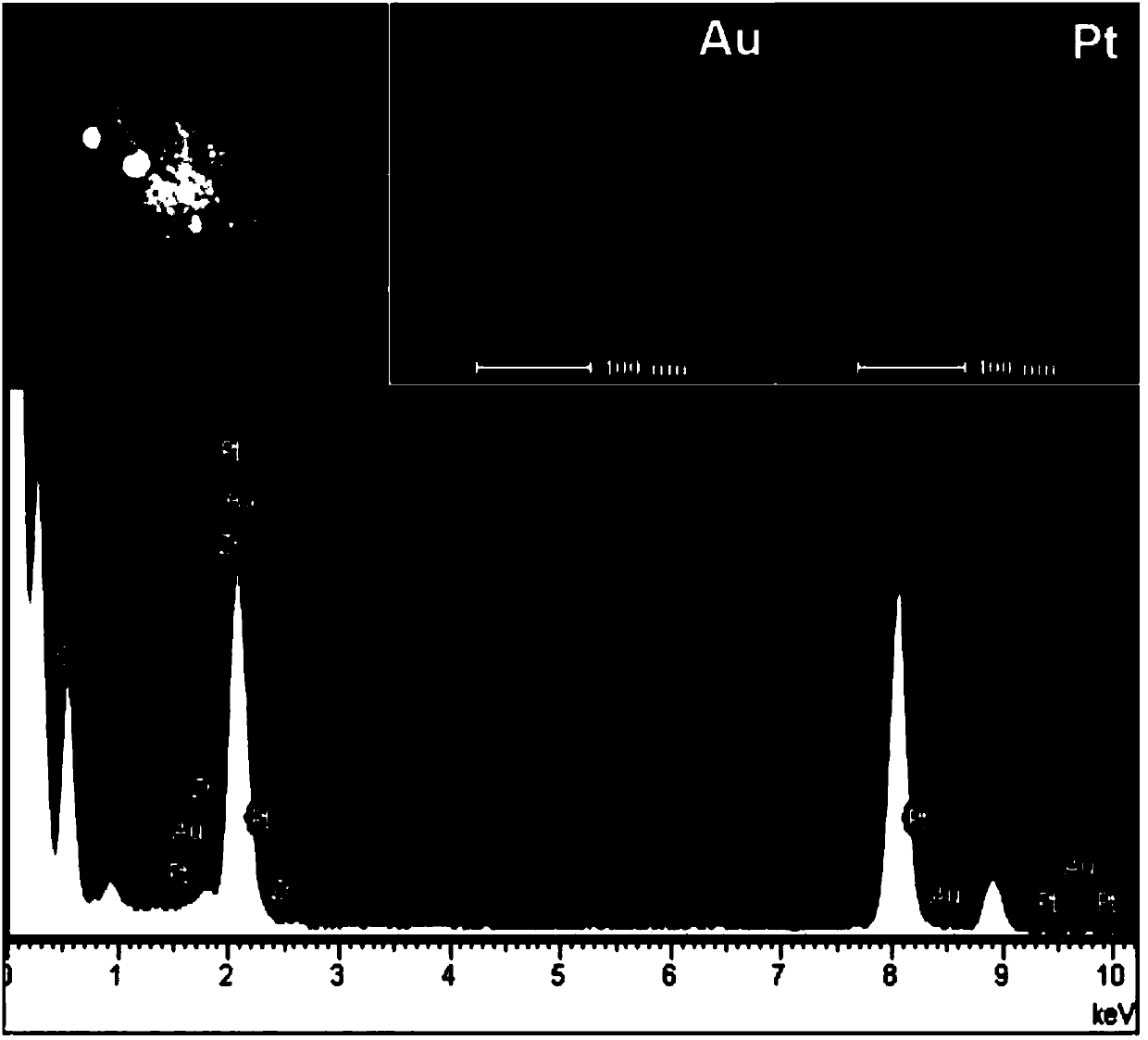

[0102] Example 1 Preparation of metal-organic frameworks simultaneously loaded with nano-gold and nano-platinum

[0103] (1) 120mgZrCl 4 1. Dissolve 96mg of terephthalic acid in a mixed solution of 4mL of glacial acetic acid and 32mL of N,N-dimethylformamide, ultrasonically mix, and then add 1mL of nano-platinum solution and mix evenly. Put the obtained mixed solution into a 45mL polytetrafluoroethylene reactor, put the reactor into a 120°C oven to react for 24 hours, and cool naturally to obtain UiO-66 loaded with nano-platinum;

[0104] (2) Immerse UiO-66 loaded with nano-platinum in 100mL 0.01% (w / v) chloroauric acid solution for 48 hours, then heat the mixed solution to boiling, and add 0.5mL 1% (w / v) sodium citrate solution Quickly add to the boiling chloroauric acid solution, stir continuously, stop heating when the solution turns purple, continue to stir until it cools down, then centrifuge, take the precipitate and dry it, and get UiO-66 composite material loaded with...

Embodiment 2

[0106] Preparation of Example 2 UiO-66 Composite Material Loaded with Nano Silver and Nano Platinum

[0107] (1) 60mg ZrCl 4 1. A mixed solution of 2 mL of glacial acetic acid and 16 mL of N, N'-dimethylformamide was ultrasonically mixed, and 48 mg of terephthalic acid was continued to be added and ultrasonically mixed to make it uniform. Then add 1 mL of nano-silver solution and mix well. The obtained mixed solution was placed in a microwave oven, heated at 1000W for 2 minutes, stopped for 2 minutes, and then heated intermittently for 10 minutes, and centrifuged to obtain UiO-66 loaded with nano-silver.

[0108] (2) According to 1g H 2 PtCl 6 Dissolve in 25mL ethanol to configure H 2 PtCl 6 ethanol solution, take 2.0mL H 2 PtCl 6 Add the ethanol solution to the UiO-66 loaded with nano-silver, stir at a constant speed at room temperature for 36 hours, then add the sodium formate solution according to the molar ratio of platinum and formic acid as 1:10, stir for 1 hour, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com