Hydraulic control mechanism for automatic clutch in hybrid electric vehicle

A hybrid electric vehicle and automatic clutch technology, applied in the field of machinery, can solve the problems of energy pulsation affecting the working performance of the switch valve, clutch hydraulic cylinder oil supply deviation, and low clutch control efficiency, so as to shorten the cost of repair and maintenance and improve Effect of control precision, improvement of control precision and response sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

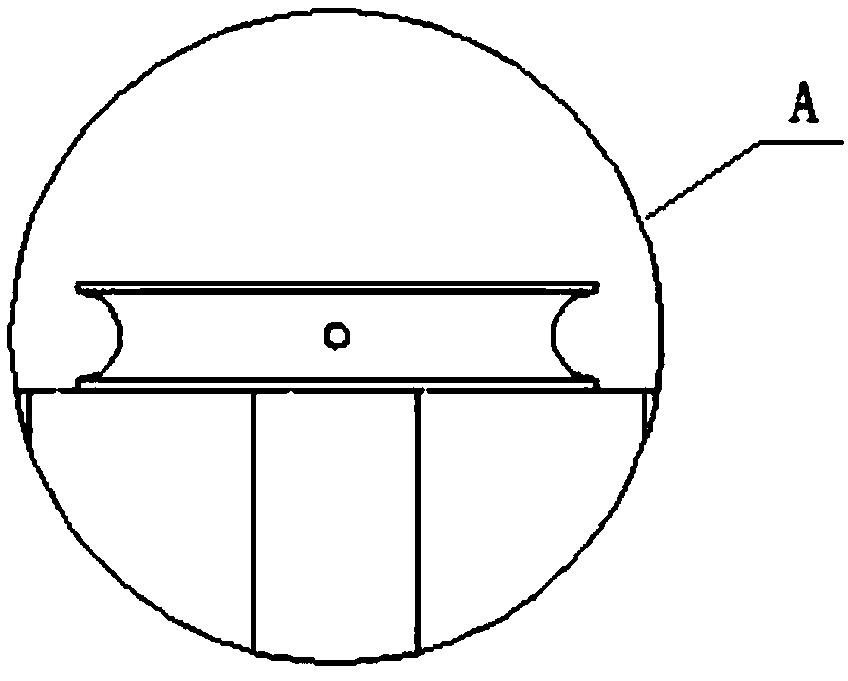

[0034] The invention provides an automatic clutch hydraulic control mechanism in a hybrid electric vehicle, such as figure 1As shown, the control mechanism includes an oil pumping system 1, an energy storage system 2, and a working cylinder system 3. A first high-pressure oil pipe 4 is connected between the energy storage system 2 and the working cylinder system 3, and the oil pumping system 1 and the energy storage system A second high-pressure oil pipe 5 and a low-pressure oil return pipe 6 are connected between the two, and a reversing valve 25 for controlling the flow direction of hydraulic oil and a pressure sensor 26 for measuring the pressure in the energy storage system 2 are installed in the energy storage system 2. An angular displacement sensor is installed in the working cylinder system 3, which is used to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com