A Viscosity Reducing Heating Device for Viscous Oil

A heating device and viscosity reduction technology, applied in isolation devices, wellbore/well components, and production fluids, etc., can solve problems such as uneven heating, equipment failure, and low heat-resistant temperature, achieve uniform and efficient transmission, and improve use. Longevity and efficient heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

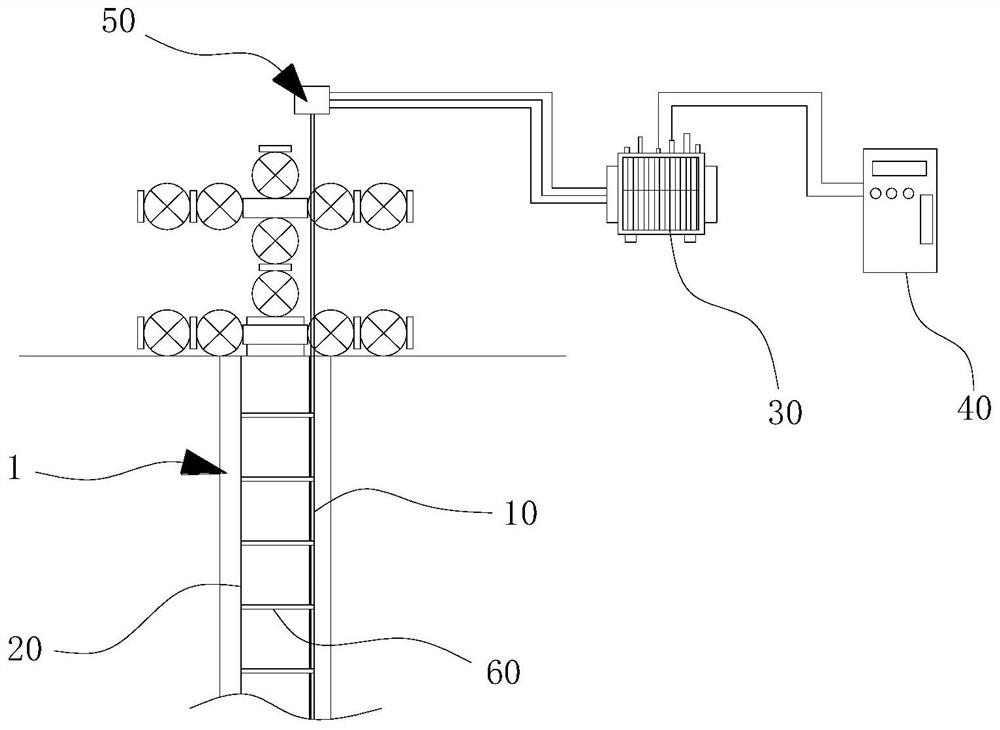

[0027] Such as figure 1 As shown, the present invention provides a heavy oil viscosity reduction heating device, including a heating cable 10, one end of the heating cable 10 extends into the oil well 1 and abuts against the wall of the oil pipe 20, and the other end extends out of the oil well 1 and forms a circuit with the power supply unit, and a transformer 30 is also provided between the power supply unit and the heating cable 10;

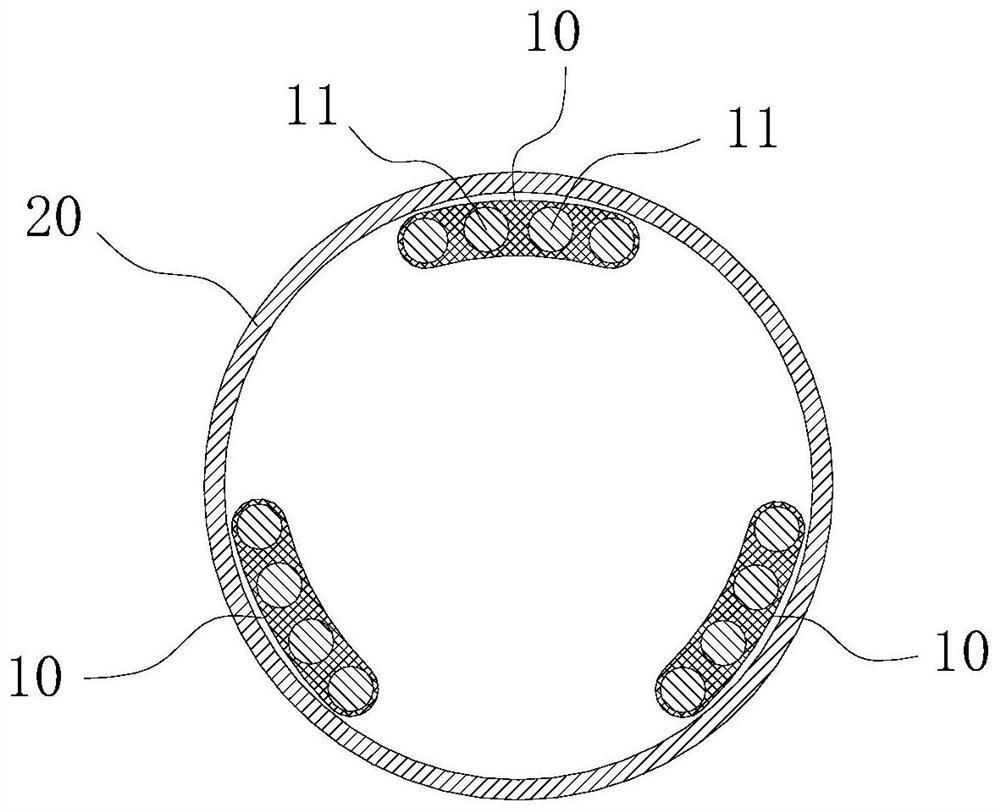

[0028] The heating cable 10 as a whole is in the shape of a flat belt, and the core wires 11 of the heating cable 10 are arranged side by side at intervals and match the curvature of the wall of the oil pipe 20 .

[0029] Further, such as Figure 5 As shown, the core wire 11 of the heating cable 10 is reciprocally laid four times along the length direction of the oil pipe 20 and the input end and output end of the core wire 11 protrude from one end of the heating cable 10 .

[0030] Further, the cable core wire 11 constituting the heating ca...

Embodiment 2

[0036] This embodiment is basically the same as the heavy oil viscosity reducing heating device in Embodiment 1, the difference is that in combination with image 3 As shown, the heating cable 10 is laid along the length direction of the oil pipe 20 and is clamped on the outer pipe wall of the oil pipe 20 by the fixing clip 60, and the rest remain unchanged.

Embodiment 3

[0038] This embodiment is basically the same as the heavy oil viscosity reducing heating device in Embodiment 1, the difference is that in combination with Figure 4As shown, the heating cable 10 is wound around the outer wall of the oil pipe 20 along the length direction of the oil pipe 20 and fixed by the fixing clip 60 .

[0039] The winding spacing of the heating cables 10 gradually decreases from the depth of the oil well 1 to the well head.

[0040] The thick oil viscosity reduction heating device provided by the present invention realizes the heating and viscosity reduction of heavy oil with relatively low heating power, avoids long-term operation of heating equipment at high power, and improves the service life of the equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com