Graphene anticorrosive paint with ultrastrong anticorrosive capability

A technology of anti-corrosion coatings and graphene, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of long coating cycle, high material cost and high construction cost, achieve good construction performance, reduce supporting coatings, Effect of reducing VOC emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

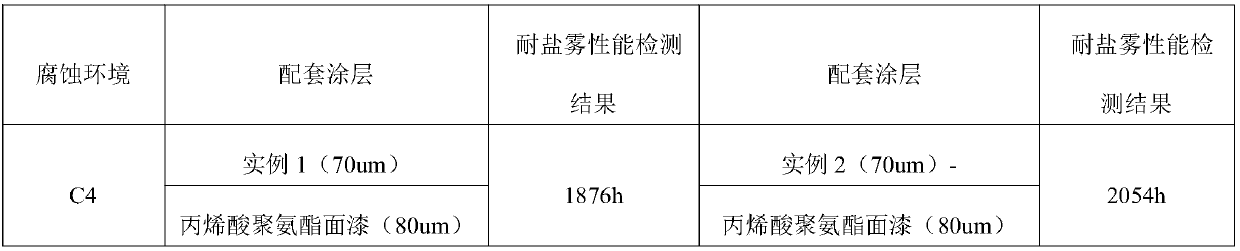

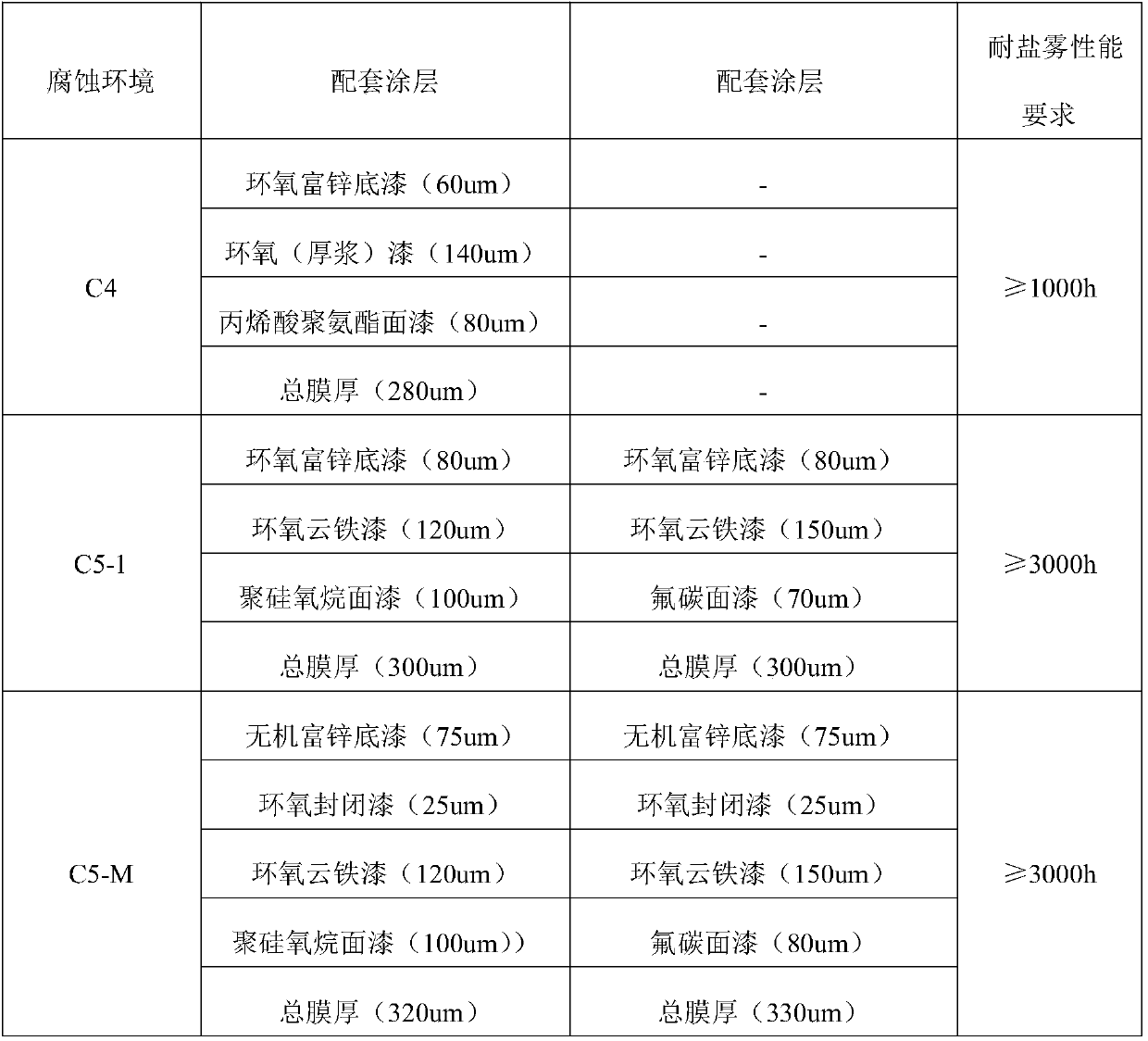

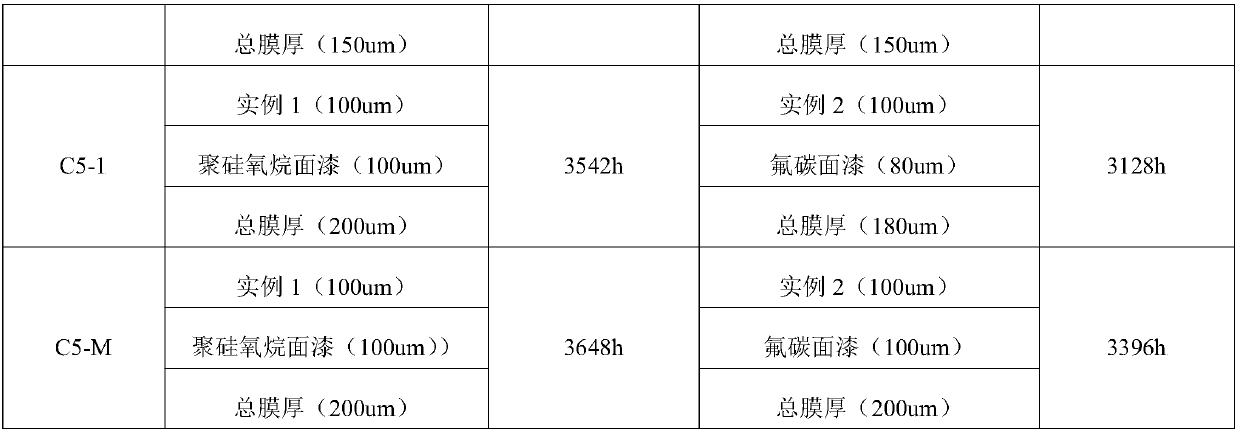

Examples

specific Embodiment 1

[0056] Preparation of graphene-infiltrated anticorrosion coatings

[0057] A component:

[0058] Step 1: Take by weighing 212Kg of modified epoxy resin liquid as modified epoxy resin, 1.8 kg of high-efficiency graphene as graphene, 0.5 kg of nonionic dispersant as dispersant, and 1.5 kg of organic bentonite as anti-sedimentation agent. kg, as the xylene 49kg of solvent, the n-butanol 31g of solvent mixes and stirs evenly; , stir and disperse for 10 minutes, grind. Grind for 45 minutes under the conditions of a rotation speed of 1369 rpm and a temperature of 28-42°C, the fineness of the ground slurry reaches 25um, and the solid content is 51% by sampling and testing, and the material is discharged for use.

[0059] Step 2: take by weighing the slurry 136kg that step 1 makes, as the modified epoxy resin liquid 48kg of modified epoxy resin, as the nonionic dispersant 0.4kg of dispersant, as the titanium dioxide 79kg of pigment filler, as 116 kg of micaceous iron oxide ash for p...

Embodiment 2

[0065] Preparation of graphene-infiltrated anticorrosion coatings

[0066] A component:

[0067] Step 1: Take by weighing 106Kg of modified epoxy resin liquid as modified epoxy resin, 0.8 kg of efficient graphene as graphene, 0.2 kg of nonionic dispersant as dispersant, 0.9 kg of organic bentonite as anti-sedimentation agent kg, as solvent xylene 33.4kg, as solvent n-butanol 21.3kg mixed and stirred evenly;, stirred and dispersed for 10 minutes, and ground. Grind for 45 minutes under the conditions of a rotation speed of 1403 rpm and a temperature of 26-45°C, the fineness of the ground slurry reaches 25um, and the solid content is 50% by sampling and testing, and the material is discharged for use.

[0068] Step 2: Take by weighing 108.6 kg of the slurry prepared in step 1, 24.7 kg of modified epoxy resin liquid as modified epoxy resin, 0.3 kg of non-ionic dispersant as dispersant, 74.5 kg of titanium dioxide as pigment and filler kg, 97kg of micaceous iron oxide ash as pigm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com