Polymer carrier for loading perfume, perfume precursor, and preparation method and application of polymer carrier

A polymer and carrier technology, applied in the direction of essential oil/fragrance, fat production, etc., can solve the problems of fragrance interference, poor adhesion strength of polymer fragrance precursors, insufficient fragrance loading rate, etc., and achieve excellent stability and high fragrance loading rate, apparent acid response properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

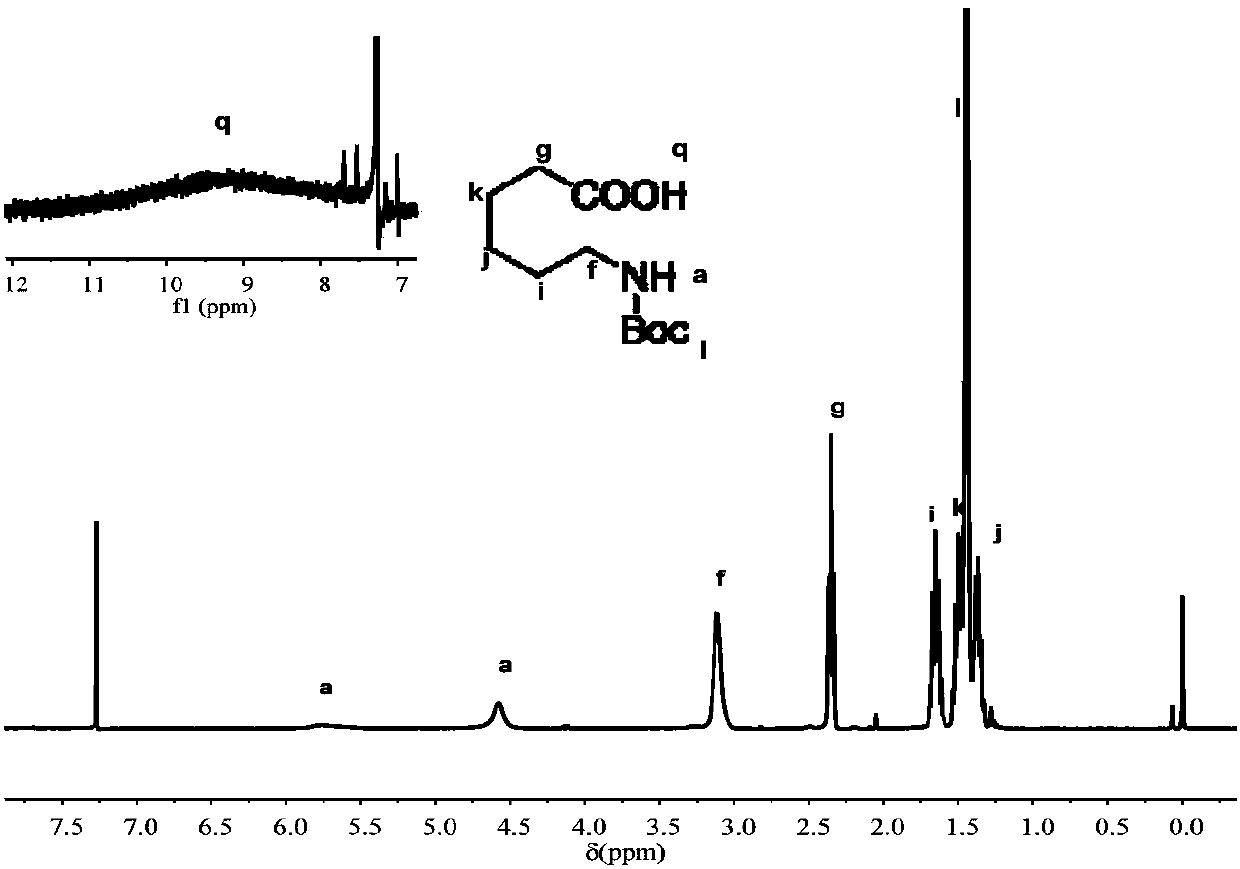

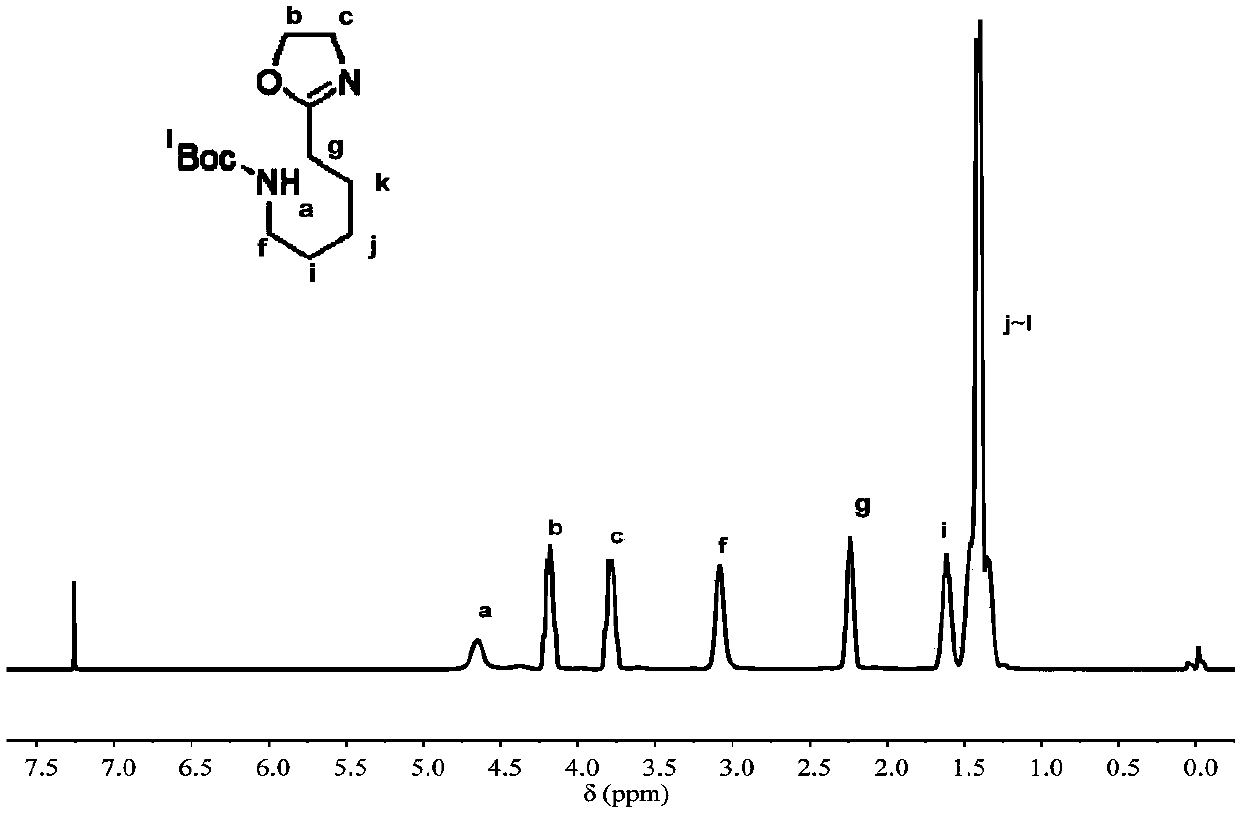

[0045] Synthesis of embodiment 1 functional monomer 2-[5-(N-tert-butoxycarbonylamino) pentyl]-2-oxazoline

[0046] synthetic route:

[0047]

[0048](1) Synthesis of 6-(N-tert-butoxycarbonylamino)caproic acid (M1): add 13.12g 6-aminocaproic acid (100.0mmol) and 80mL aqueous sodium hydroxide solution (3.5mol / L) in a flask, Stir to dissolve, then add 26.19g di-tert-butyl dicarbonate (Boc 2 O, 120.0 mmol), a white turbid solution was formed after 24 hours of reaction at room temperature. Remove the ice bath, add 2mol / L hydrochloric acid drop by drop to decompose excess Boc 2 O, the reaction solution first produced a large number of bubbles, and gradually became clear, and then re-formed a milky white turbid solution, and stopped adding hydrochloric acid until the pH value was neutralized to 3 to 4; the mixed solution was extracted three times with ethyl acetate, and the organic layer was used. Back extraction with deionized water, then adding anhydrous magnesium sulfate pow...

Embodiment 2

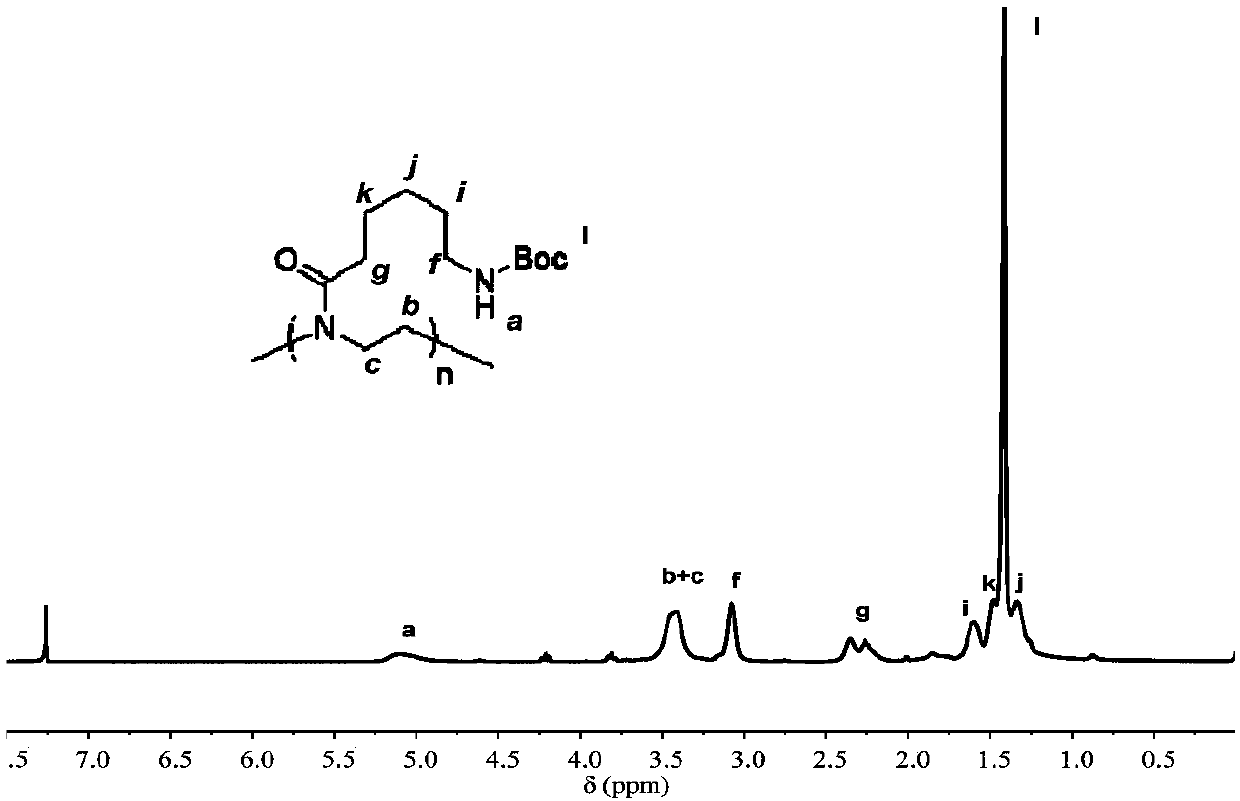

[0053] The synthesis of embodiment 2 homopolymer P'1

[0054] synthetic route:

[0055]

[0056] The polymerization bottle is connected to the latex tube, the tee, the latex tube in turn, and connected to the anhydrous and oxygen-free operating system. After vacuuming, high-temperature baking, cooling, and nitrogen gas, the water and oxygen in the reaction device are removed. Under nitrogen protection, drop into functional monomer M, initiator (Sc(OTf) 3 acetonitrile solution or MeOTs acetonitrile solution) and solvent acetonitrile (monomer concentration is 2mol / L); after the monomer is dissolved, the polymerization bottle is put into a Dewar flask filled with liquid nitrogen under the condition of nitrogen gas, and pumped after 20s Vacuum until a white solid is formed inside the polymerization bottle, stop vacuuming, take out the polymerization bottle and put it in water, refill nitrogen after the solid melts, repeat the above steps three times, remove oxygen in the syste...

Embodiment 3

[0061] The synthesis of embodiment 3 copolymer P1:

[0062] synthetic route:

[0063]

[0064] The polymerization bottle is vacuumized, baked at high temperature, cooled, and ventilated with nitrogen to remove water and oxygen. Under the protection of nitrogen, put functional monomer M and initiator (Sc(OTf) 3 or the acetonitrile solution of MeOTs) and the solvent acetonitrile, after the monomer is dissolved, put the polymerization bottle into liquid nitrogen to evacuate to form a solid, then take out the polymerization bottle and put it in water, fill it with nitrogen after the solid melts, repeat three times, and then put The sealed polymerization bottle is placed in an oil bath at 90°C for reaction t 1 Time, get functional monomer block, then add 2-ethyl-2-oxazoline, continue reaction t 2 time, and finally 0.1 mL of piperidine was added to terminate the reaction. The post-processing method is the same as in Example 2, and the characterization results are shown in Tab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com