Numerical-control automatic loading mechanism of ceramic-tile polishing equipment

A technology for automatic feeding and ceramic tiles, which is applied in the field of mechanical polishing, can solve the problems of tile damage and high labor intensity, and achieve the effects of improving efficiency, reducing labor costs, and avoiding tile bumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

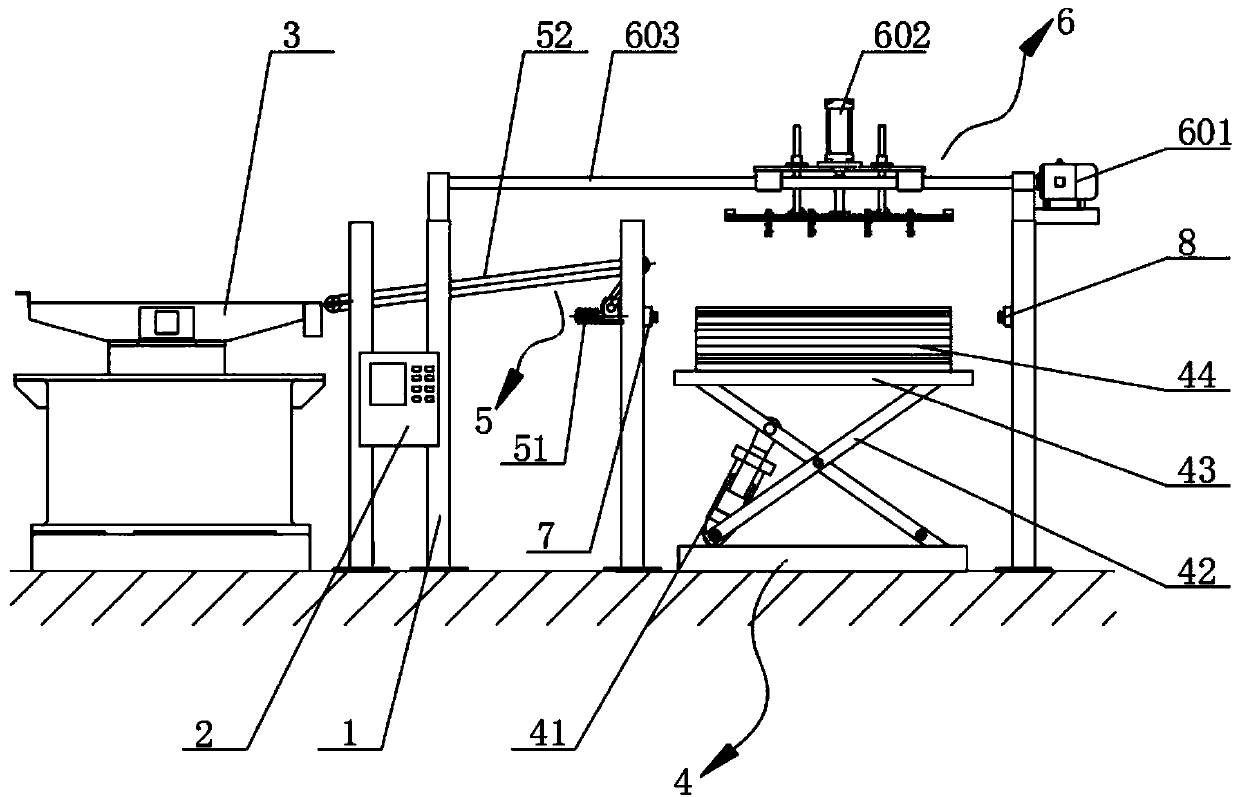

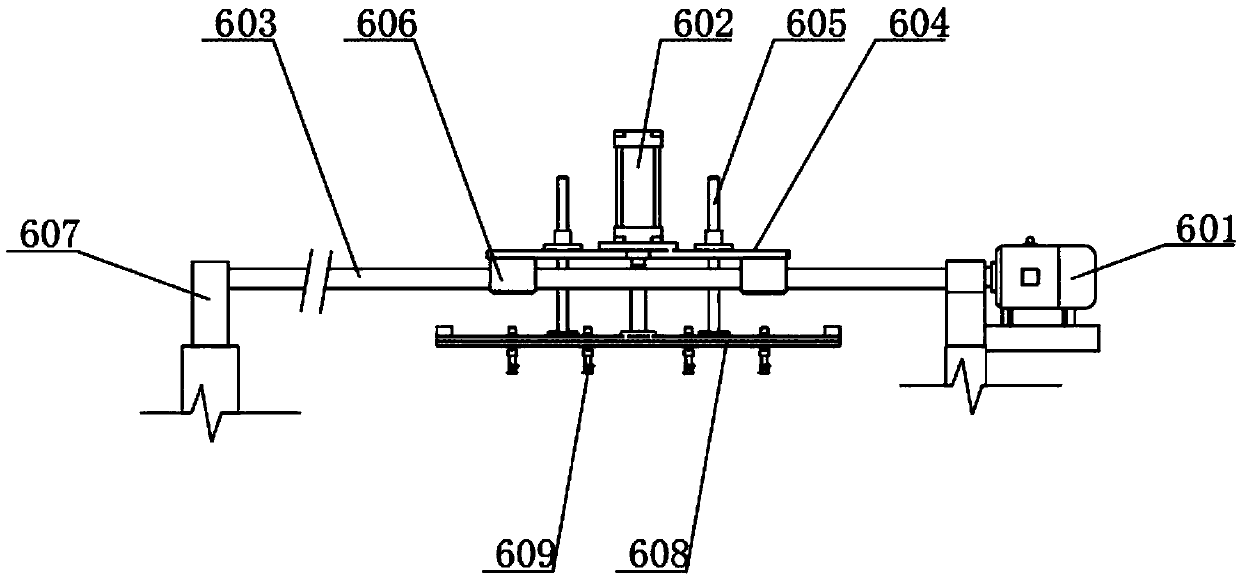

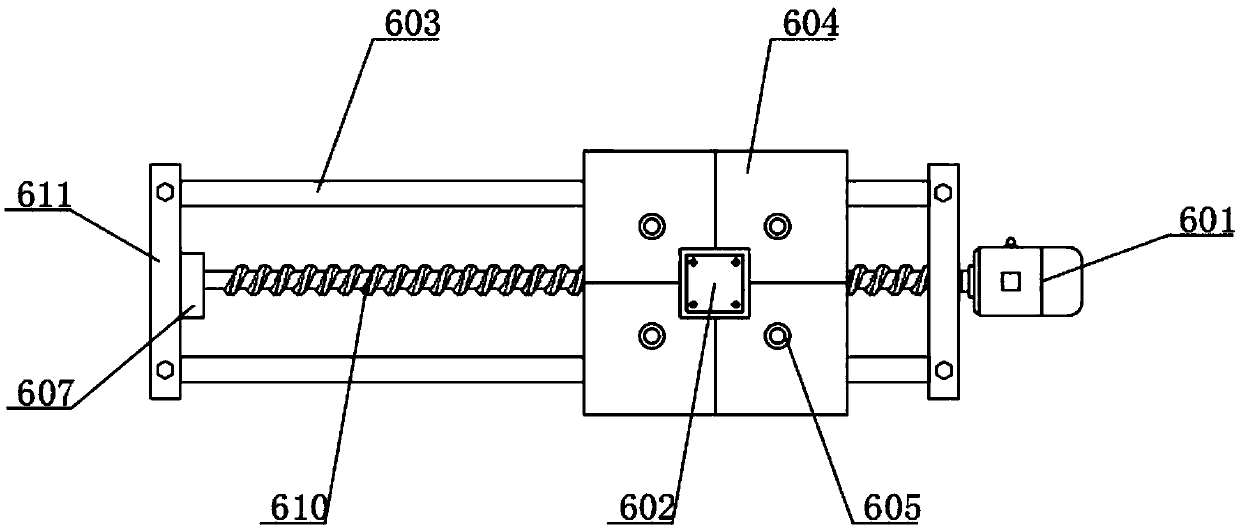

[0021] as attached figure 1 to attach image 3 Shown:

[0022] The invention provides a numerically controlled automatic feeding mechanism for ceramic tile polishing equipment, including a frame 1, a PLC controller 2, a polishing table 3, a material preparation mechanism 4, a hydraulic cylinder 41, an inner gallows 42, a material table 43, ceramic tiles 44, and a transmission mechanism 5. Transmission drive mechanism 51, conveyor belt 52, transfer mechanism 6, motor 601, cylinder 602, horizontal guide rod 603, cylinder mounting plate 604, vertical guide rod 605, slider 606, bearing 607, suction cup frame 608, suction cup 609, Screw rod 610, fixed plate 611, laser emitter 7 and laser receiver 8; Transmission mechanism 5 comprises transmission drive mechanism 51 and conveyor belt 52; Transmission drive mechanism 51 is installed on the frame 1; The top of conveyor belt 52 guiding polishing table 3; Stock preparation The mechanism 4 is located on the right side of the transmissi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com