A method for forming tantalum alloy special-shaped parts

A technology for tantalum alloy and special-shaped parts, which is applied in the field of forming tantalum alloy special-shaped parts. The effect of the ear phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

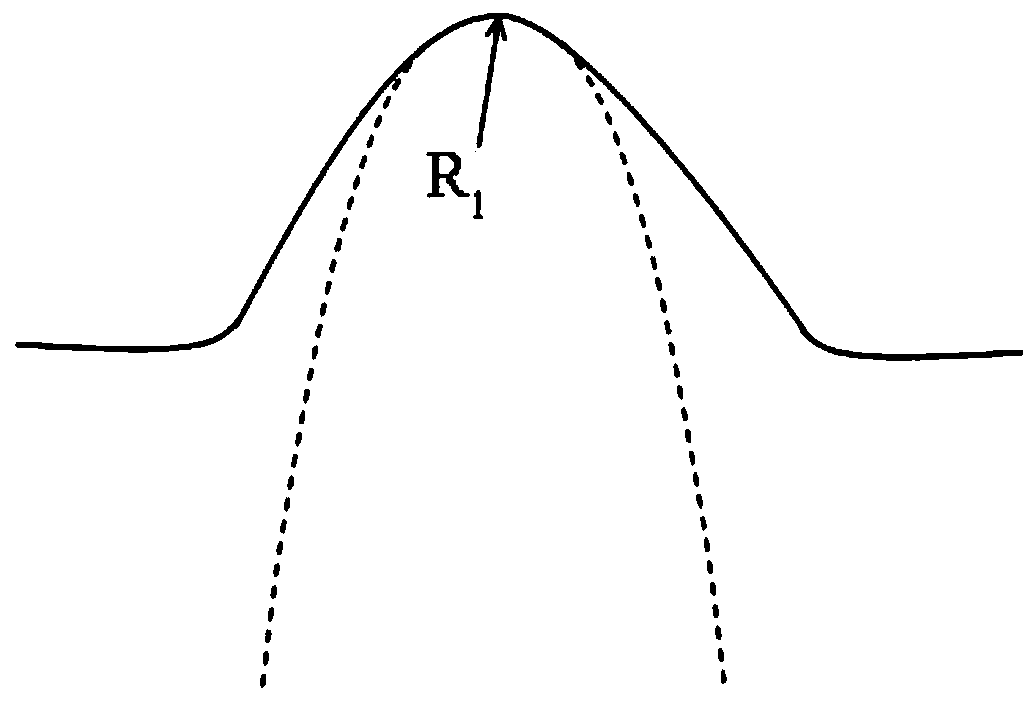

[0025] Such as figure 2 As shown, in the forming process of TaNb3 special-shaped parts in this embodiment, the solid line indicates the stamping forming part, the dotted line indicates the spinning forming part, R 1 Indicates the top radius of the semi-finished TaNb3 special-shaped part.

[0026] This embodiment includes the following steps:

[0027] Step 1. Cut the TaNb3 plate obtained by cross rolling into a TaNb3 disc with a diameter of 500 mm and a thickness of 20 mm. After polishing the surface of the TaNb3 disc, heat it to 200 ° C and keep it warm for 10 minutes, and then stamp it in 2 passes , to obtain the TaNb3 special-shaped piece semi-finished product; the top radius R of the TaNb3 special-shaped piece semi-finished product 1 60mm, cone angle 90°;

[0028] Step 2. Place the TaNb3 special-shaped semi-finished product obtained in step 1 on a spinning machine for spinning, and use graphite mechanical oil mixture to lubricate. After 5 passes of cold spinning, a bull...

Embodiment 2

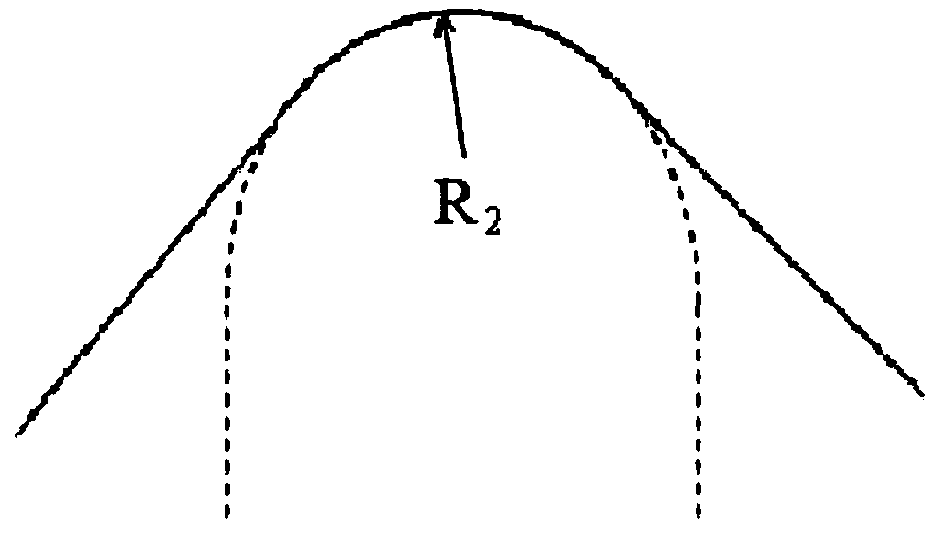

[0032] Such as image 3 As shown, in the forming process of TaNb20 special-shaped parts in this embodiment, the solid line indicates the stamping forming part, the dotted line indicates the spinning forming part, R 2 Indicates the top radius of the semi-finished TaNb20 special-shaped part.

[0033] This embodiment includes the following steps:

[0034] Step 1. Cut the TaNb20 plate obtained by cross-rolling into TaNb20 discs with a diameter of 325mm and a thickness of 15mm. After polishing the surface of the TaNb20 disc, heat it to 200°C and keep it warm for 10 minutes, and then stamp it in one pass , to obtain the semi-finished TaNb20 special-shaped piece; the top radius R of the semi-finished TaNb20 special-shaped piece 2 is 85mm, and the cone angle is 120°;

[0035] Step 2. Place the semi-finished TaNb20 special-shaped piece obtained in step 1 on a spinning machine for spinning, and use a graphite mechanical oil mixture to lubricate. After 7 passes of cold spinning, a TaN...

Embodiment 3

[0040] Such as Figure 5 As shown, in the forming process of TaW10 special-shaped parts in this embodiment, the solid line indicates the stamping forming part, and the dotted line indicates the spinning forming part, Φ 1 Indicates the outer diameter of the bottom of the semi-finished TaW10 special-shaped part.

[0041] This embodiment includes the following steps:

[0042] Step 1. Cut the TaW10 plate obtained by cross-rolling into TaW10 discs with a diameter of 200mm and a thickness of 13mm. Polish the surface of the TaW10 disc and apply an anti-oxidation coating, then heat to 600°C and keep it warm for 20min , and then through 3 times of stamping, the bowl-shaped TaW10 special-shaped semi-finished product is obtained; the bottom outer diameter of the bowl-shaped TaW10 special-shaped semi-finished product is Φ 1 80mm;

[0043] Step 2. Put the TaW10 special-shaped semi-finished product obtained in step 1 on a spinning machine for hot spinning, lubricate with graphite mechani...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com