Chitosan-based metal ion adsorbent and preparation method thereof

An ion adsorbent, chitosan technology, applied in the directions of alkali metal compounds, chemical instruments and methods, adsorbed water/sewage treatment, etc. and other problems, to achieve the effect of increasing adsorption active points and adsorption area, low production cost and increasing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

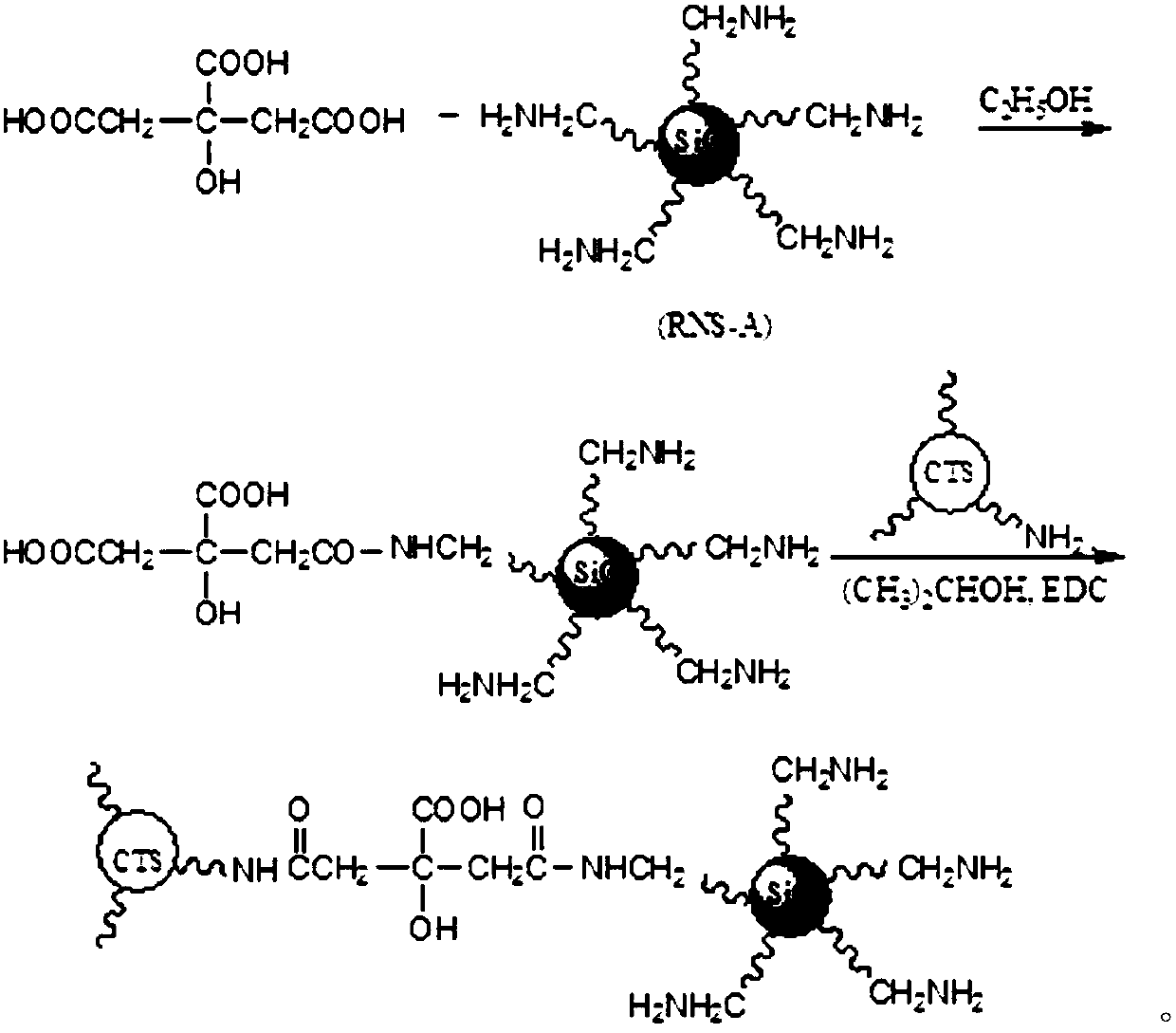

[0026] The chitosan-based metal ion adsorbent of this embodiment is prepared by the following method:

[0027] 1) Disperse 3g RNS-A in 80mL of absolute ethanol, then add 3g of citric acid, stir the reaction at 30℃ for 2h, cool, filter with suction, wash the filter cake with absolute ethanol, and dry it in vacuum at 35℃ for 3h to obtain White powdery solid, that is, the RNS-A modification of citric acid as modified citric acid;

[0028] 2) Disperse 2g of chitosan in 50mL of isopropanol, stir for 30min, add 2g of RNS-A modified citric acid and 0.5g of 1-ethyl-(3-dimethylaminopropyl) carbodisulfide Amine, stirred and reacted at 50℃ for 6h, cooled, filtered with suction, the filter cake was washed with isopropanol and acetone, and dried in vacuum at 45℃ for 5h to obtain milky white particles, namely RNS as a chitosan-based metal ion adsorbent -A modified chitosan grafted with citric acid.

[0029] Raw material and product characterization:

[0030] Use infrared spectroscopy to character...

Embodiment 2

[0035] The chitosan-based metal ion adsorbent of this embodiment is prepared by the following method:

[0036] 1) Disperse 3g RNS-A in 80mL of absolute ethanol, then add 2g of citric acid, stir the reaction at 25℃ for 3h, cool and filter with suction. After the filter cake is washed with absolute ethanol, it is vacuum dried at 30℃ for 4h to obtain White powdery solid, that is, the RNS-A modification of citric acid as modified citric acid;

[0037] 2) Disperse 2g of chitosan in 40mL of isopropanol, stir for 30min, add 1g of RNS-A modified citric acid and 0.3g of 1-ethyl-(3-dimethylaminopropyl) carbon dioxide Imine, stirred and reacted at 45℃ for 7h, cooled, filtered with suction, the filter cake was washed with isopropanol and acetone, and dried in vacuum at 40℃ for 6h to obtain milky white particles, which are used as chitosan-based metal ion adsorbents RNS-A modified citric acid grafted chitosan.

Embodiment 3

[0039] The chitosan-based metal ion adsorbent of this embodiment is prepared by the following method:

[0040] 1) Disperse 3g RNS-A in 80mL absolute ethanol, then add 4g citric acid, stir the reaction at 35℃ for 1h, cool, filter with suction, the filter cake is washed with absolute ethanol, and dried in vacuum at 40℃ for 2h to obtain White powdery solid, that is, the RNS-A modification of citric acid as modified citric acid;

[0041] 2) Take 2g of chitosan and disperse it in 60mL of isopropanol. After stirring for 30min, add 3g of RNS-A modified citric acid and 1g of 1-ethyl-(3-dimethylaminopropyl) carbodioxide Amine, stirred and reacted at 55°C for 5h, cooled, filtered with suction, the filter cake was washed with isopropanol and propanol, and dried in vacuum at 50°C for 4h to obtain milky white particles, which are used as chitosan-based metal ion adsorbents RNS-A modified citric acid grafted chitosan.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com