Superhydrophilic underwater-superlipophobic oil-water separation membrane, and preparation method thereof

An underwater superoleophobic, oil-water separation membrane technology, applied in semi-permeable membrane separation, chemical instruments and methods, membrane technology, etc. problem, to achieve the effect of low cost, inhibition of movement, and reduction of crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

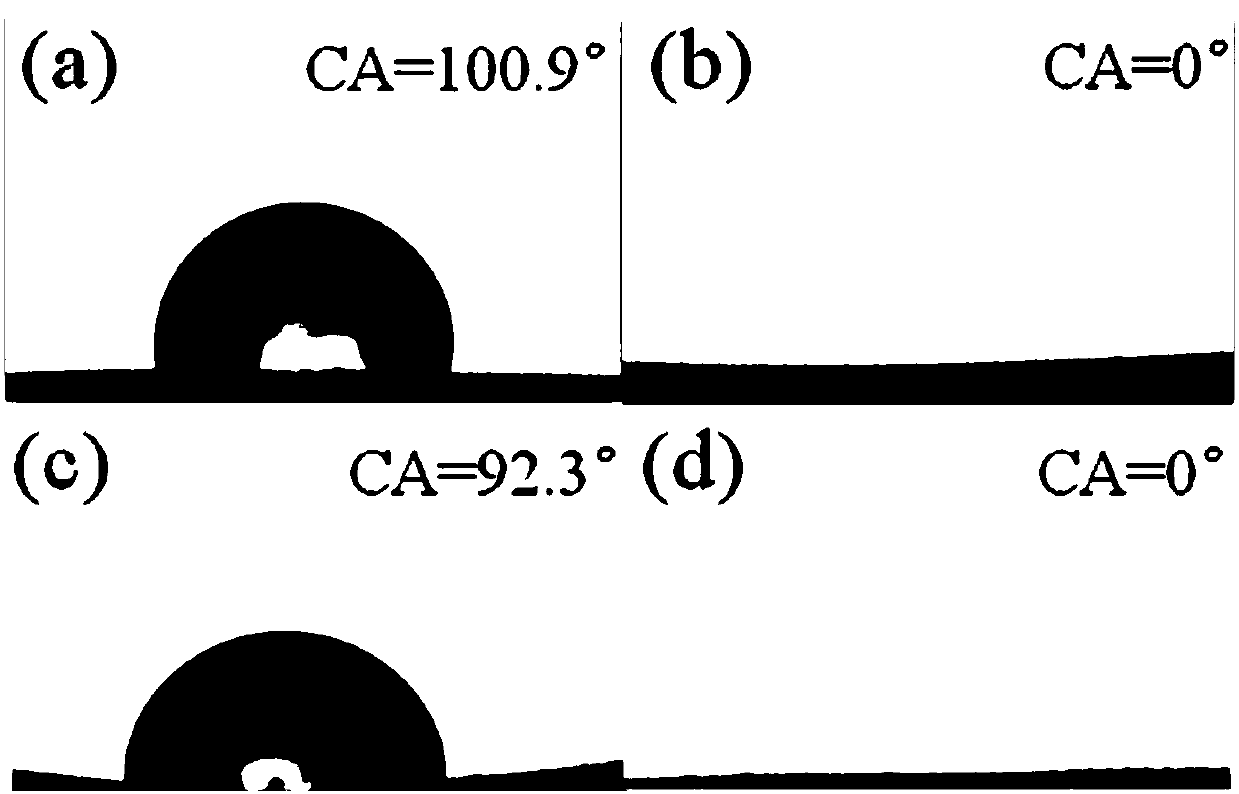

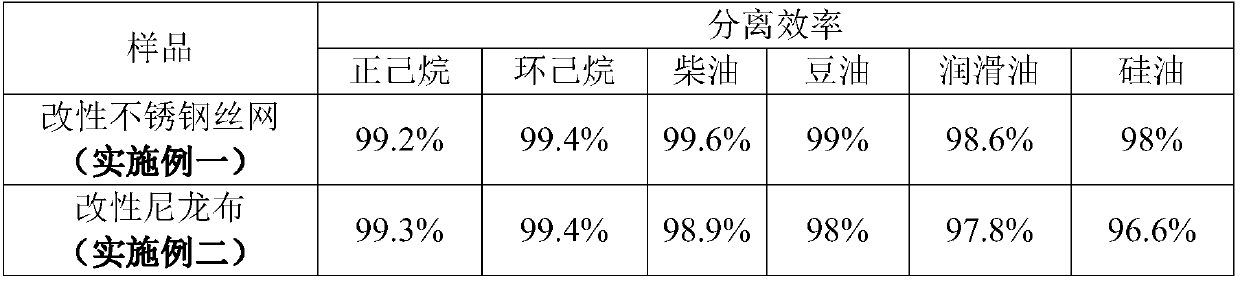

[0028] In this example, see figure 1 and figure 2 , a method for preparing an underwater super-oleophobic oil-water separation membrane with a polymer and nanoparticle composite coating, comprising the following steps:

[0029] a. Pretreatment of the fabric mesh base material: use stainless steel wire mesh with a mesh number of not less than 300 mesh as the fabric mesh base material, and clean the stainless steel mesh with anhydrous acetone ultrasonically for 15 minutes to remove organic matter on the surface of the stainless steel mesh, Then use absolute ethanol to wash away the residual acetone on the surface of the stainless steel wire mesh, continue to ultrasonically clean it with deionized water for 15 minutes to remove impurities on the surface of the stainless steel mesh, and finally dry the clean stainless steel wire mesh at 60°C for 1 hour to obtain a clean and dry product. stainless steel wire mesh;

[0030] b. preparing an aqueous solution of polyvinyl alcohol 17...

Embodiment 2

[0034] This embodiment is basically the same as Embodiment 1, especially in that:

[0035] In this example, see figure 1 and figure 2 , a method for preparing an underwater super-oleophobic oil-water separation membrane with a polymer and nanoparticle composite coating, comprising the following steps:

[0036]a. Pretreatment of fabric omentum base material: use nylon cloth with a mesh number of not less than 300 mesh as the fabric omentum base material, first clean the nylon cloth with anhydrous acetone ultrasonically for 15 minutes, remove the organic matter on the surface of the nylon cloth, and then clean it with anhydrous acetone Rinse off the residual acetone on the surface of the nylon cloth with water and ethanol, continue ultrasonic cleaning with deionized water for 15 minutes to remove impurities on the surface of the nylon cloth, and finally dry the clean nylon cloth at 60°C for 1 hour to obtain a clean and dry nylon cloth;

[0037] b. preparing an aqueous solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| oil-water separation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com