Preparation method of strontium-improved nickel-cobalt-manganese ternary material

A ternary material, nickel-cobalt-manganese technology, used in electrical components, electrochemical generators, battery electrodes, etc., can solve the problem that the chemical composition of samples at room temperature is difficult to be consistent, the precipitation of nickel and cobalt ions is incomplete, and the precipitation conditions are quite different, etc. problem, to achieve the effect of excellent discharge performance, good consistency, and low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

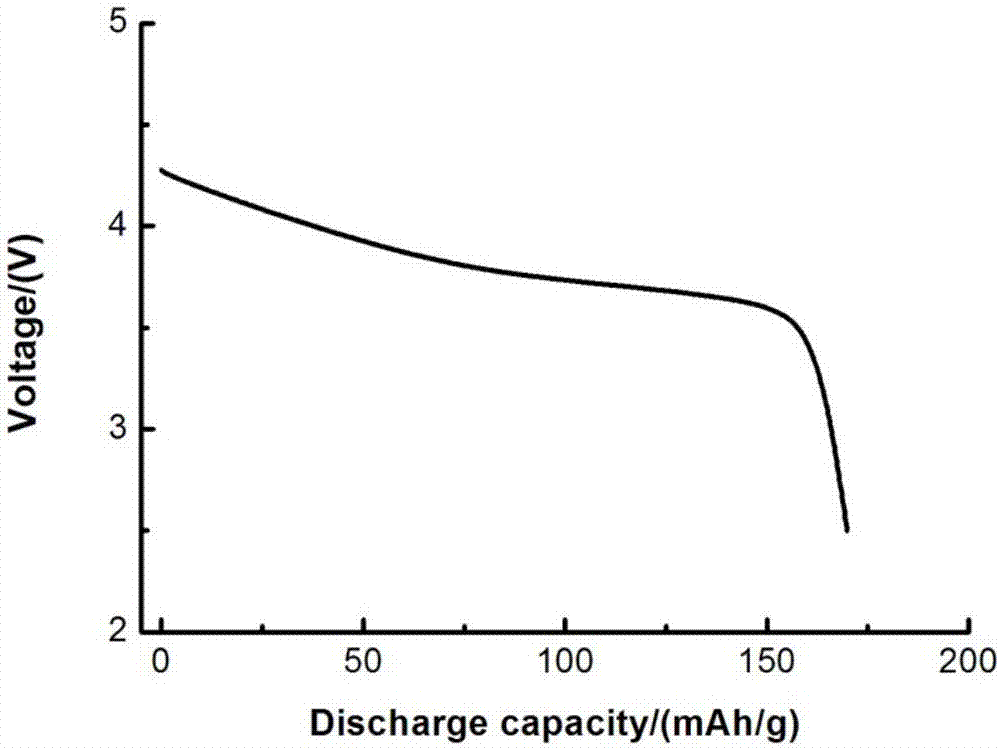

Embodiment 1

[0048] Nickel acetate, cobalt acetate, manganese carbonate, lithium hydroxide and strontium oxide were weighed according to the molar ratio of nickel, cobalt, manganese, lithium, and doped strontium ions of 0.49:0.19:0.3:1.06:0.08. Mixture 1 was obtained by mixing nickel acetate, cobalt acetate, manganese carbonate and strontium oxide. Add 3 times the volume of deionized water of the total volume of mixture 1, and mix evenly; add ammonia water dropwise under continuous stirring until the acidity of the solution is pH 12.5, add weighed lithium hydroxide, mix evenly through a ball mill, and mix in a nitrogen atmosphere and aging at 85°C for 24 hours to obtain precursor 2. Precursor 2 was heated at 230° C. under a vacuum condition of 0.1 atmosphere to prepare dry precursor 3 . Precursor 3 was placed in an oxygen atmosphere, heated from room temperature to 850 °C at a rate of 5 °C / min, and cooled to room temperature to prepare a layered α-NaFeO 2 Structural, strontium-modified n...

Embodiment 2

[0051] Nickel oxide, cobalt nitrate, manganese acetate, lithium nitrate and strontium oxide were weighed according to the molar ratio of nickel, cobalt, manganese, lithium, and doped strontium ions: 0.47:0.17:0.30:1.01:0.07. Mixture 1 was obtained by mixing nickel oxide, cobalt nitrate, manganese acetate and strontium oxide. Add 1 times the volume of deionized water to the total volume of mixture 1, and mix well. Under the condition of continuous stirring, ammonia water was added dropwise to the acidity pH of the solution to 13.5, and the weighed lithium citrate was added, mixed evenly by sand milling equipment, and aged in an argon atmosphere at 60°C for 48 hours to prepare precursor 2. Precursor 2 was spray-dried at 120 °C to prepare dry precursor 3. Precursor 3 was placed in an oxygen atmosphere, heated from room temperature to 880 °C at a rate of 10 °C / min, and cooled to room temperature to prepare a layered α-NaFeO 2 Structural, strontium-modified nickel-cobalt-manganes...

Embodiment 3

[0054] Nickel nitrate, cobalt carbonate, manganese hydroxide, lithium nitrate and strontium nitrate were respectively weighed according to the molar ratio of nickel, cobalt, manganese, lithium, and doped strontium ions of 0.52:0.19:0.19:0.98:0.08. Mixture 1 was obtained by mixing nickel nitrate, cobalt carbonate, manganese hydroxide and strontium nitrate. Add 80 times the volume of deionized water of the total volume of the mixture 1, mix well, add ammonia water dropwise under continuous stirring until the acidity of the solution is pH 10.5, add the weighed lithium nitrate, mix uniformly by a ball mill, and mix in a helium atmosphere and Precursor 2 was obtained by aging at 90° C. for 48 hours. Precursor 2 was heated at 120° C. under a vacuum condition of 0.9 atmospheric pressure to prepare dry precursor 3 . Precursor 3 was placed in an oxygen atmosphere, heated from room temperature to 880 °C at a rate of 0.1 °C / min, and cooled to room temperature to prepare a layered α-NaFe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com