Metal lithium negative electrode piece, preparation method thereof and metal lithium secondary battery

A metal lithium and negative electrode technology, which is applied in the repair/maintenance of secondary batteries, lithium batteries, battery electrodes, etc., can solve problems such as the inability to completely eliminate the influence of lithium dendrite growth, and improve safety performance and cycle performance. Effect of large actual surface area and reduced risk of short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

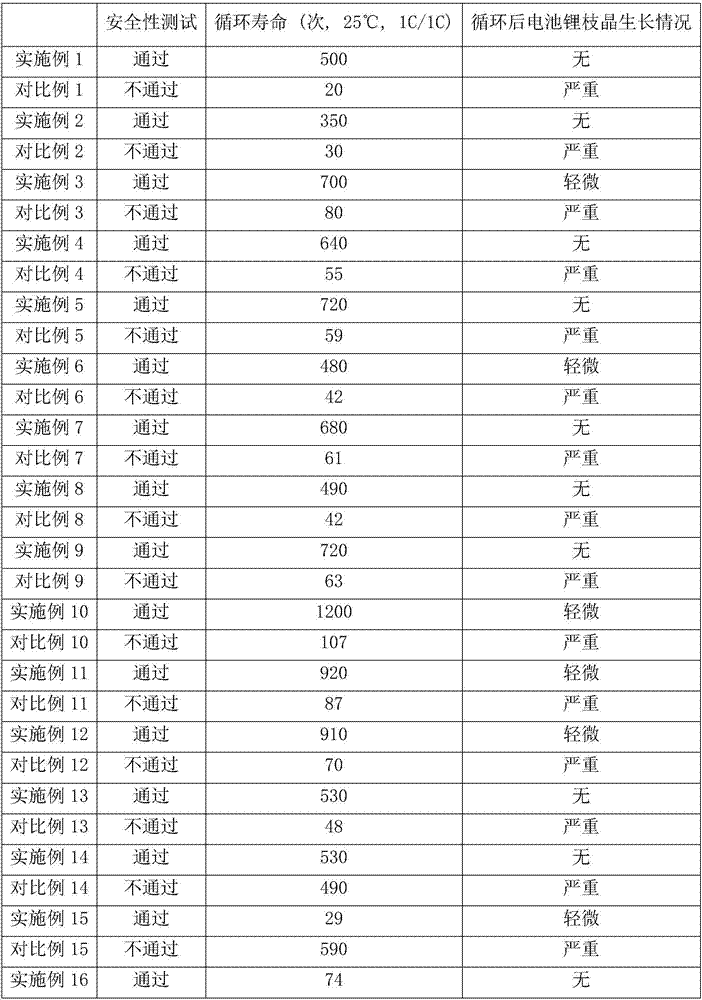

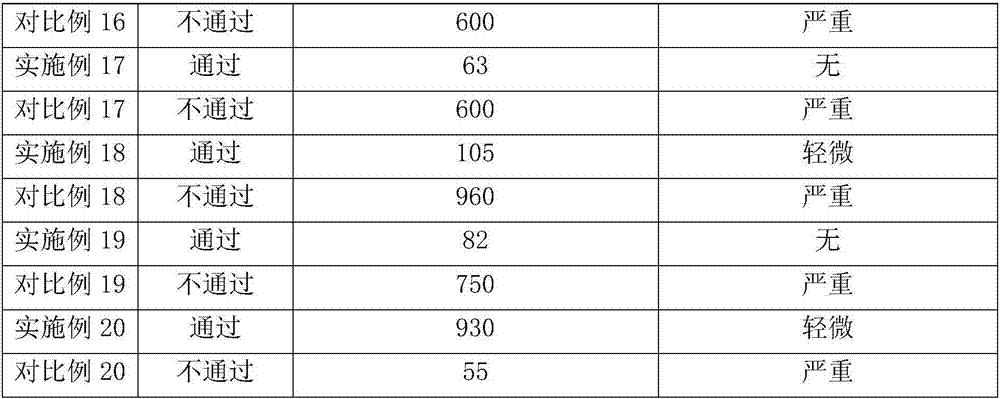

Examples

Embodiment 1

[0049] Press the 500μm metal lithium foil and the copper grid current collector together;

[0050] Dissolve PEO in acetonitrile to make a polymer electrolyte solution with a concentration of 1%, add Super P (the mass ratio of Super P to PEO is 1:99) into the polymer electrolyte solution and stir evenly, and spread the mixed solution on the set On the fluid metal lithium layer, the solvent is evaporated to dryness, and a composite conductive film with a thickness of 0.1 μm is formed on the surface of the metal lithium layer to obtain a metal lithium negative electrode sheet.

[0051] The positive electrode sheet is prepared by a conventional method. The positive electrode active material on the positive electrode sheet is lithium iron phosphate, and the metal lithium negative electrode sheet, lithium iron phosphate positive electrode sheet, and separator are wound by a winding process, and a lithium battery is made with a liquid electrolyte.

Embodiment 2

[0055] Coating a layer of 1 μm metal lithium layer on the surface of copper foil by vacuum evaporation method;

[0056] PVDF-HFP was dissolved in N,N-dimethylformamide (DMF) to make a polymer electrolyte solution with a concentration of 10%, and carbon nanotubes (the mass ratio of carbon nanotubes to PVDF-HFP was 99:1 ) was added into the polymer electrolyte solution and stirred evenly, the mixed solution was coated on the metal lithium layer of the current collector, the solvent was evaporated to dryness, and a composite conductive film with a thickness of 1 μm was formed on the metal lithium surface to obtain a metal lithium negative electrode sheet.

[0057] The positive electrode sheet is prepared by a conventional method. The positive electrode active material on the positive electrode sheet is lithium iron phosphate, and the metal lithium negative electrode sheet, lithium iron phosphate positive electrode sheet, and separator are laminated by a lamination process, and the...

Embodiment 3

[0061] A metal lithium layer of 5 μm is plated on the surface of the etched copper foil by vacuum evaporation method;

[0062] Dissolve the polycarbonate polymer in acetone to make a polymer electrolyte solution with a concentration of 50%, add acetylene black (the mass ratio of acetylene black to polycarbonate polymer is 50:50) into the polymer electrolyte solution and stir evenly, Coating the mixed solution on a substrate with a smooth surface, evaporating the solvent to obtain a composite film with a thickness of 100 μm, and pressing the composite film on the surface of the lithium metal layer by rolling to obtain a lithium metal negative electrode sheet.

[0063] The positive electrode sheet is prepared by a conventional method. The positive electrode active material on the positive electrode sheet is lithium iron phosphate, and the metal lithium negative electrode sheet and the lithium iron phosphate positive electrode sheet are laminated with a solid electrolyte to form a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com