Organosilicon pigment as well as preparation method and use method thereof

A technology of organosilicon and organopolysiloxane, which is applied in art paints, antifouling/underwater paints, biocide-containing paints, etc., can solve the production hazards of human body and environment, and remove the old varnish layer, which is cumbersome and difficult to operate Meet other problems, to achieve good oxygen resistance and anti-aging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] A method for preparing organosilicon pigments, comprising a step of preparing component A and component B;

[0054] A component preparation step: add organopolysiloxane, filler, toner, silicone resin, organohydrogen polysiloxane, tackifier and reaction inhibitor in a mixer according to the proportion, mix for 1-3 hours, then grind, Finally, it was cooled to room temperature to obtain composition A;

[0055] Steps for preparing component B: add organopolysiloxane and reaction catalyst in a mixer according to the ratio, mix for 0.5-1 hour, and cool to room temperature to obtain composition B;

[0056] Mixing step: Mix composition A and composition B in a weight ratio of (5-10):1 to obtain a pigment.

[0057] The third objective of the present invention can be achieved by adopting the following technical solutions:

[0058] A method of using organosilicon pigments, including:

[0059] Dilution step: add a viscosity modifier to dilute the pigment, wherein the weight ratio of the visc...

Embodiment 1-5

[0071] Examples 1-5 are silicone pigments, each of which is prepared from component A and component B; the proportions of component A and component B are shown in the following table.

[0072] Table 1 Components and ratios of Examples 1-5

[0073]

[0074]

[0075] Among them, the weight ratio of the A component and the B component of Example 1 is 5:1; under room temperature conditions, complete curing can be achieved in 1 hour.

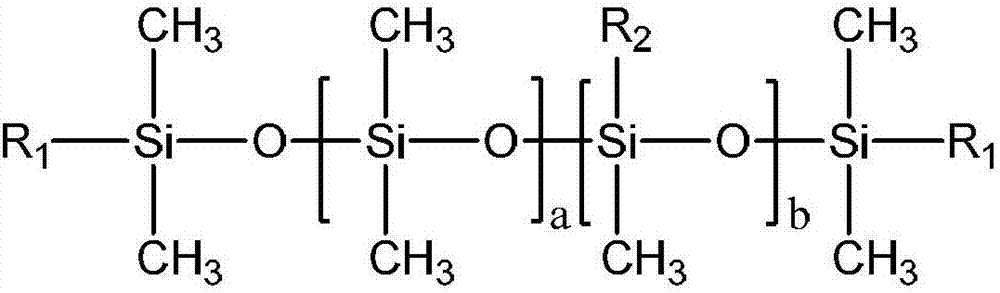

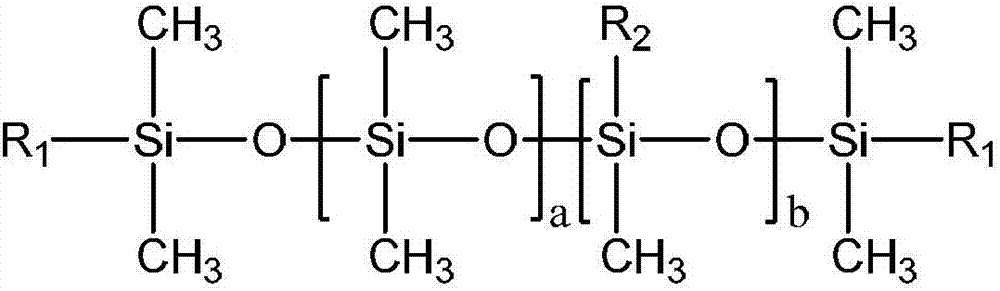

[0076] Organopolysiloxane has the following molecular structure:

[0077]

[0078] In the formula, a=500, b=0; where R 1 For -CH=CH 2 ;

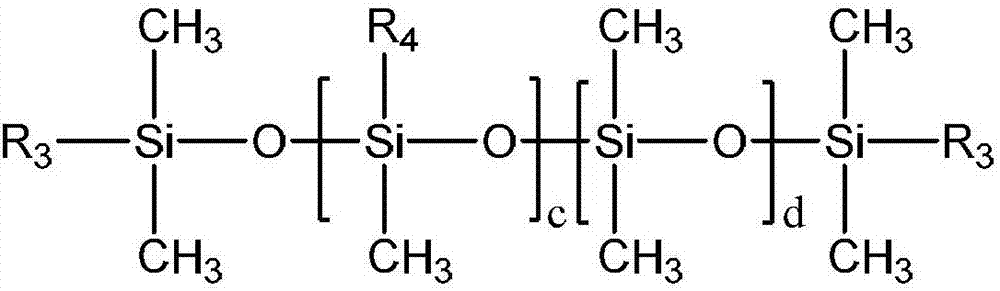

[0079] The molecular structure of organohydrogen polysiloxane is as follows:

[0080]

[0081] In the formula, c=20, d=40; where R 3 Is methyl, R 4 Is a hydrogen radical;

[0082] Silicone resin has the following molecular structure:

[0083] [(CH 3 ) 3 SiO 1 / 2 ] e [(CH 2 =CH)(CH 3 ) 2 SiO 1 / 2 ] f [SiO 4 / 2 ] g

[0084] In the formula, e=0.6, f=0.1, g=1;

[0085] The filler has a specific surface area of 100m 2 / g, bulk density ...

Embodiment 2

[0086] The weight ratio of the A component and the B component of Example 2 is 6:1; under room temperature conditions, complete curing can be achieved within 1.5 hours.

[0087] Organopolysiloxane has the following molecular structure:

[0088]

[0089] In the formula, a=400, b=50; where R 1 For -CH=CH 2 , R 2 Is methyl;

[0090] The molecular structure of organohydrogen polysiloxane is as follows:

[0091]

[0092] In the formula, c=10, d=50; where R 3 Is methyl, R 4 Is a hydrogen radical;

[0093] Silicone resin has the following molecular structure:

[0094] [(CH 3 ) 3 SiO 1 / 2 ] e [(CH 2 =CH)(CH 3 ) 2 SiO 1 / 2 ] f [SiO 4 / 2 ] g

[0095] In the formula, e=0.6, f=0.2, g=1;

[0096] The filler has a specific surface area of 150m 2 / g, bulk density 100kg / m 3 The fumed silica; reaction inhibitor is methyl butynol; reaction catalyst is chloroplatinic acid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com