Method for separating and purifying capsaicin and dihydrocapsaicin from pepper fruits

A technology for the separation and purification of dihydrocapsaicin, applied in the separation/purification of carboxylic acid amide, organic chemistry, bulk chemical production, etc., can solve the problems of low extraction rate and separation and purification efficiency of capsaicin, and achieve high yield High, avoid short service life, good reproducibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

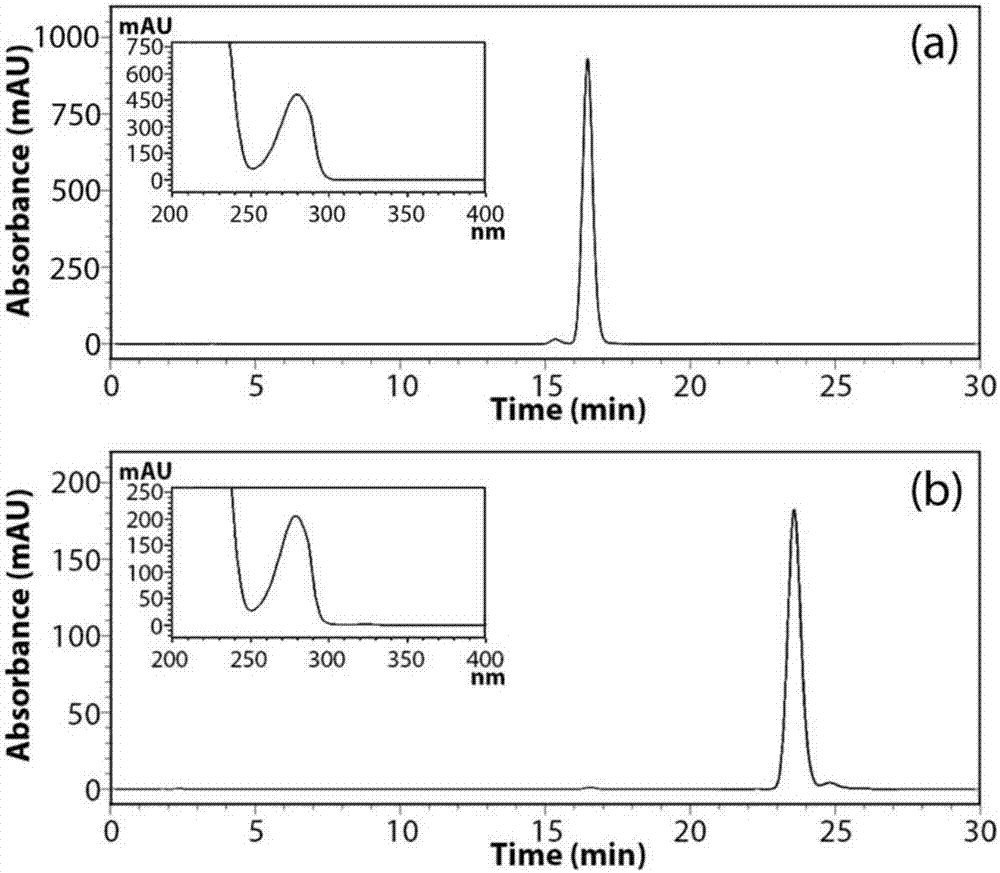

[0057] Example 1 A method of separating and purifying capsaicin and dihydrocapsaicin from capsicum fruit

[0058] A method for separating and purifying capsaicin and dihydrocapsaicin from capsicum fruit, comprising the following 4 steps:

[0059] 1. Supercritical carbon dioxide extraction

[0060] After crushing the dried chili fruit, pass through a 40-mesh sieve, take 100 g of chili powder, and place it in 1 L of supercritical CO 2 In the extraction kettle; the CO 2 Cool to 4°C and pump it into the system at a flow rate of 20L / h; the extraction pressure is 33MPa, the extraction temperature is 41°C, the amount of ethanol entrainer is 75mL, and the extraction time is 90min; 45°C, the pressure of the analytical kettle II is 5Mpa, and the temperature of the analytical kettle II is 60°C; the products in the analytical kettle I and the analytical kettle II are combined and concentrated under reduced pressure below 45°C to obtain 18.44g of capsicum oleoresin.

[0061] 2. Methanol...

Embodiment 2

[0077] Respectively with n-hexane: ethyl acetate: methanol: water = 1: 10: 1: 5, n-hexane: ethyl acetate: methanol: water = 10: 1: 5: 1, n-hexane: ethyl acetate: methanol: water =8:2:3:5 is the solvent system of high-speed countercurrent chromatography, and the remaining steps are the same as in Example 1 for the separation and purification of capsaicin and dihydrocapsaicin. The obtained capsaicin and dihydrocapsaicin have a purity greater than 96.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com