Preparation technique of stable non-stoichiometry nanometer cerium dioxide particles

A nano-cerium dioxide, non-stoichiometric technology, applied in nanotechnology, inorganic chemistry, nanotechnology, etc. for materials and surface science, can solve the problem of low, non-existent, and poor stability of nano-cerium dioxide average oxygen vacancies and other problems, to achieve the effect of high oxygen vacancy content, high oxygen vacancy content, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: A kind of technique of preparing stable non-stoichiometric nano ceria particles, the steps are as follows:

[0034] 1) Grind cerium carbonate to a particle size of less than 20 μm, and then put it in a drying oven at 100°C for 12 hours to dry and dehydrate to obtain product A;

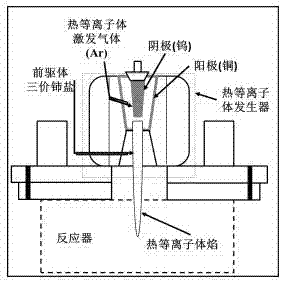

[0035] 2) Use a thermal plasma generator to excite argon gas (the flow rate of argon gas is 39L / min) into a thermal plasma flame, and use argon gas (the flow rate of argon gas is 3L / min) to carry product A to the thermal plasma In the reactor, the power of the thermal plasma generator is controlled to be 20kW, so that product A is completely reacted in the thermal plasma flame to obtain product B;

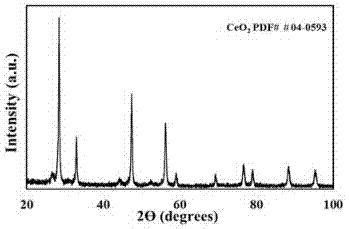

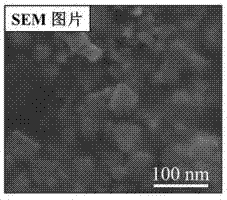

[0036] 3) The product B is transported to the collector with the airflow for collection, and the particle size is less than 100 nm, the oxygen vacancy concentration is 22%, and the blue powdery non-stoichiometric nano-cerium oxide particles are obtained.

Embodiment 2

[0037] Embodiment 2: A kind of technique of preparing stable non-stoichiometric nano ceria particles, the steps are as follows:

[0038] 1) Grind cerium carbonate, cerium nitrate or cerium chloride to a particle size of less than 20 μm, and then put it in a drying oven at 80°C for 15 hours to dry and dehydrate to obtain product A;

[0039] 2) Use a thermal plasma generator to excite argon gas (the gas flow rate of argon is 30L / min) into a thermal plasma flame, using argon, hydrogen or argon and hydrogen mixed gas (gas flow rate of 1L / min) Carry product A into a thermal plasma reactor, control the power of the thermal plasma generator to 10kW, let product A react completely in the thermal plasma flame, and obtain product B;

[0040] 3) The product B is transported to the collector with the airflow for collection, and the particle size is less than 100 nm, the oxygen vacancy concentration is 15%, and the blue powdery non-stoichiometric nano-cerium oxide particles are obtained. ...

Embodiment 3

[0041]Embodiment 3: A kind of technique of preparing stable non-stoichiometric nano ceria particles, the steps are as follows:

[0042] 1) Grind cerium carbonate, cerium nitrate or cerium chloride to a particle size of less than 20 μm, and then put it in a drying oven at 120°C for 10 hours to dry and dehydrate to obtain product A;

[0043] 2) Use a thermal plasma generator to excite argon gas (the gas flow rate of argon is 60L / min) into a thermal plasma flame, using argon, hydrogen or argon and hydrogen mixed gas (gas flow rate of 6L / min) Carry product A into a thermal plasma reactor, control the power of the thermal plasma generator to 30kW, let product A react completely in the thermal plasma flame, and obtain product B;

[0044] 3) The product B is transported to the collector with the airflow for collection, and the particle size is less than 100 nm, the oxygen vacancy concentration is 30%, and the blue powdery non-stoichiometric nano-cerium oxide particles are obtained. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com